Date: 2025-12-30

Introduction: The Building Blocks of Your Electronic Device

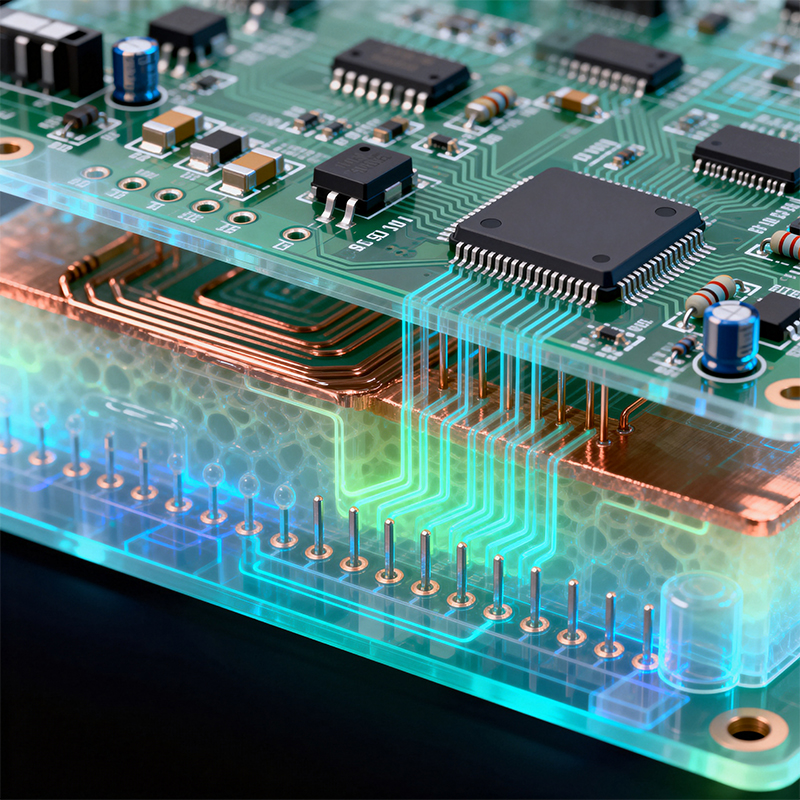

Imagine a printed circuit board (PCB) as a miniature city. The green board itself is the land and the roads. But what brings this city to life? The answer is the components on a PCB — the tiny “buildings” and “infrastructure” that perform all the electronic functions.

If you design, source, or manufacture electronics, understanding these common parts is crucial. It helps you communicate clearly with suppliers, optimize designs, and ensure your product’s quality. Let’s meet the key residents of this electronic city.

Meet the Residents: Common Components on a PCB

Components can be broadly split into two families by how they are installed: Surface Mount Device (SMD) parts that sit flat on the board, and Through-Hole Technology (THT) parts that have long leads poking through holes. Here are the most essential ones:

Resistors (SMD & THT): The Traffic Regulators

What they do: They resist the flow of electrical current, acting like narrow sections of road that control “traffic” (current). They’re used to set voltage levels, limit current, and divide signals.

On the board: SMD resistors look like tiny black rectangles or cylinders with numbers on them. THT resistors are colorful cylinders with wire legs.

Capacitors (SMD & THT): The Tiny Energy Reservoirs

What they do: They store and release electrical energy quickly, like mini rechargeable batteries or water tanks. They smooth out power supply fluctuations, filter noise, and control timing in circuits.

On the board: They can look like small, flat ceramic chips or tiny metal cans (SMD), or larger cylindrical barrels (THT).

Integrated Circuits (ICs) / Microchips (Mostly SMD): The City’s Brain and Specialists

What they do: These are the most complex components. A single IC, which is a small black rectangle with many tiny metal legs, can contain millions of transistors. They act as the brains (like microprocessors and microcontrollers), memory storage, or specialized function units (like signal amplifiers or power regulators).

On the board: They are often the most prominent SMD components, secured with precise solder connections.

Connectors (SMD & THT): The City Gates

What they do: These are the interfaces where your PCB connects to the outside world—power, USB cables, antennas, or other boards.

On the board: They are usually among the largest components, like USB ports, pin headers, or screw terminals.

Other Key Citizens:

Inductors/Coils (SMD & THT): Store energy in a magnetic field, used in power supplies and radio circuits.

Diodes (SMD & THT): One-way valves for electricity, allowing current to flow in only one direction. LEDs are a popular light-emitting type.

Crystals/Oscillators (SMD & THT): The PCB’s clock, providing a precise timing signal for the ICs to operate in sync.

Why the Right Components and Assembly Matter More Than You Think

Choosing the correct components is just the first step. A successful product relies on:

Correct Specifications: A capacitor with the wrong voltage rating can fail.

Authentic Quality: Counterfeit or low-grade components lead to early field failures.

Precise Assembly: Even the best part fails if it’s misaligned or poorly soldered.

This is where your PCBA partner’s expertise becomes critical. A great partner manages the entire journey from design support and component sourcing to flawless assembly.

Simplify Your Build with Kaboer, Your Partner in Shenzhen

Managing a global supply chain for dozens of tiny parts is complex. Kaboer, with our own PCBA factory in Shenzhen, China, streamlines this entire process for global brands.

How Kaboer Masters the World of PCB Components:

Informed Component Selection: Our engineers review your Bill of Materials (BOM) to suggest reliable, cost-effective alternates and help avoid obsolete or hard-to-source parts.

Trusted Supply Chain Access: Located in Shenzhen, we leverage direct relationships with authorized distributors and component manufacturers. We handle sourcing, procurement, and BOM cost optimization, ensuring genuine parts at competitive prices.

Precision Assembly & Inspection: Our automated SMT lines place thousands of components per hour with micron-level accuracy. Post-assembly, every board is scrutinized by Automated Optical Inspection (AOI) and X-ray to verify perfect soldering, especially under dense ICs.

Complete Solution from One Location: From initial PCB fabrication and component kitting to assembly, testing, and box-build, we provide a seamless, vertically integrated service. You get a single point of contact and responsibility.

Conclusion: Great Products Start with Great Foundations

The components on a PCB are the fundamental building blocks of your device’s functionality, performance, and longevity. Partnering with a manufacturer that masters both the selection and assembly of these parts is a strategic advantage.

Ready to build your next electronic product on a solid foundation? Contact Kaboer today to discuss your component needs and PCBA project. Let us handle the complexity, so you can focus on innovation.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..