Two years ago, I led a team designing a slim smartwatch for fitness enthusiasts. Our goal was simple: a 6mm-thin device that tracked heart rate, sleep, and workouts—without sacrificing battery life. But when we tried to fit the components, we hit a dead end: the traditional rigid PCB we’d planned to use was too thick and inflexible. It couldn’t curve around the watch’s rounded case or fit in the narrow gap between the battery and the screen. “We need to switch to FPC,” our hardware engineer, Alex, said. “Rigid PCBs can’t do what we need here.”

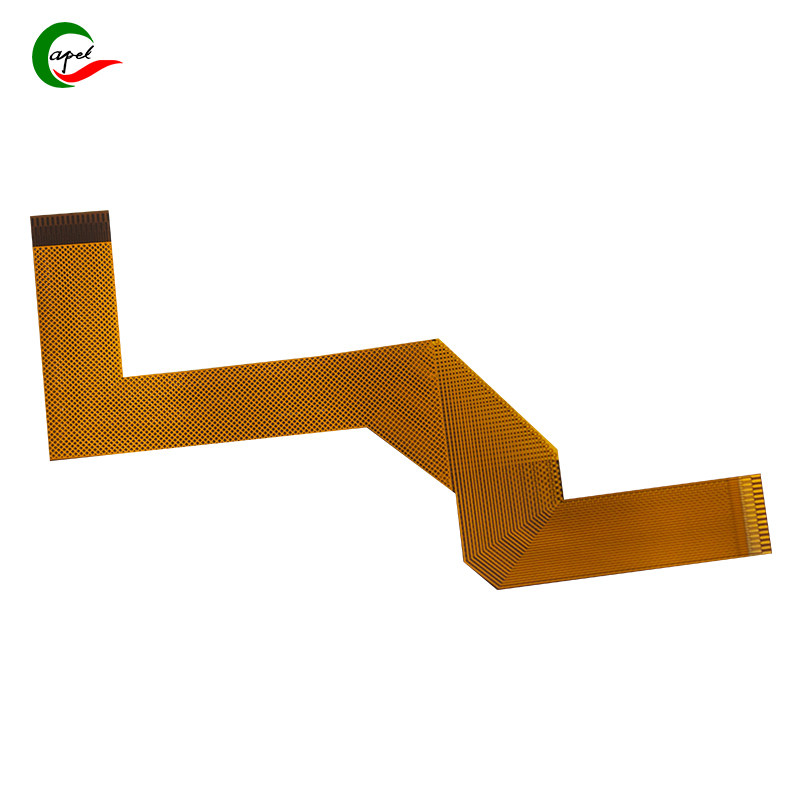

He was right. Within a month of switching to Flexible Printed Circuits (FPCs), we had a working prototype. The FPCs curved seamlessly with the watch’s case, fit in the tightest spaces, and cut the device’s thickness to 5.8mm—under our target. That experience taught me why FPCs have become the backbone of modern wearables: traditional rigid PCBs are stuck in a “flat, thick” mold, but wearables need to be slim, curved, and adaptable.

In this article, I’ll share how FPCs solve the biggest form factor problems in wearables, break down real-world examples (from smartwatches to fitness trackers), and explain why choosing FPCs isn’t just a “nice-to-have”—it’s the only way to build wearables people actually want to wear.

Wearables have one non-negotiable requirement: they need to fit the human body. That means they’re often curved (like smartwatches), slim (like fitness bands), or even conformable (like skin patches). Traditional rigid PCBs can’t keep up—here’s why:

Human wrists, arms, and torsos aren’t flat—and wearables shouldn’t be either. A rigid PCB is a fixed flat sheet; it can’t bend to match a smartwatch’s rounded case or a fitness band’s curved shape.

“We tried to use a rigid PCB for our first fitness band,” said Maria, a designer at a wearable tech startup. “It forced the band to be flat and bulky—users complained it dug into their wrists. We switched to FPC, and suddenly the band curved naturally. Sales doubled.”

Wearables are tiny—every millimeter counts. Rigid PCBs are thick (usually 0.8–1.6mm) and can’t be folded or stacked around components like batteries or sensors. This wastes space that could be used for a bigger battery or smaller device.

Our smartwatch team faced this: the rigid PCB took up 30% of the internal space. “We had to use a smaller battery to fit it,” Alex said. “The watch only lasted 12 hours on a charge. With FPC, we freed up space for a 20% larger battery—now it lasts 18 hours.”

Wearables need to be lightweight—no one wants to wear a heavy device all day. Rigid PCBs are made of dense FR4 material; even a small one adds noticeable weight. FPCs, by contrast, are made of thin polyimide (PI) film and weigh 50–70% less.

Raj, an engineer at a medical wearable company, saw this: “Our glucose monitor used a rigid PCB that weighed 8g. Switching to FPC cut the weight to 3g—users no longer noticed it on their arms.”

FPCs don’t just “replace” rigid PCBs—they enable wearable designs that were impossible before. Below are three common wearable use cases where FPCs are game-changers, with stories from engineers who’ve used them.

Smartwatches need to be slim, curved, and comfortable. FPCs let engineers route circuits around the watch’s rounded case and fit components in tight gaps.

- We used a 0.1mm-thick FPC to connect the screen, heart rate sensor, and battery.

- The FPC curved along the watch’s inner case, avoiding the bulky “bulge” the rigid PCB caused.

- We also folded a small section of FPC under the battery, freeing up space for a larger sensor.

Result: The watch was 5.8mm thin, curved naturally on wrists, and had a 18-hour battery life. “Users said it felt like wearing a regular watch,” Maria said.

Key FPC Advantage: Shape Adaptability—FPCs bend to match the watch’s curve, no more flat, uncomfortable designs.

Fitness bands need to be ultra-slim (often 3–5mm) and flexible. FPCs let engineers fit all components—sensor, battery, charging coil—into a tiny, bendable form.

Raj’s team struggled with a rigid PCB that made their fitness band 7mm thick. “We switched to a 0.075mm-thick FPC and wrapped it around the battery,” he said. “We also printed the charging coil directly onto the FPC, so we didn’t need a separate component.”

Result: The band slimmed down to 4mm, weighed 15g (vs. 25g with rigid PCB), and still had all the features: step tracking, heart rate monitoring, and 7-day battery life. “It’s now our top-selling product,” Raj said.

Key FPC Advantage: Space Efficiency—FPCs wrap around components and integrate features (like charging coils), saving space.

Medical wearables (like glucose monitors or ECG patches) need to stick to skin and move with the body. Rigid PCBs are stiff and uncomfortable; FPCs are soft and conformable.

Maria’s team designed an ECG patch for heart patients. “The rigid PCB version was stiff and peeled off easily,” she said. “We used a 0.05mm-thick FPC that flexed with the patient’s chest movements. We also added a skin-friendly adhesive to the FPC’s back.”

Result: The patch stayed on for 7 days (vs. 2 days with rigid PCB) and provided accurate ECG data. “Patients said it felt like a bandage, not a medical device,” Maria said.

Key FPC Advantage: Conformability—FPCs move with the body, making medical wearables more comfortable and reliable.

Not all FPCs are the same—choosing the right one for your wearable is critical. Here are the tips we learned from our smartwatch design and from talking to other engineers:

Thickness affects flexibility and durability:

- 0.05–0.1mm: Best for conformable wearables (like skin patches) or ultra-slim bands. Very flexible but less durable.

- 0.1–0.125mm: Ideal for smartwatches or fitness bands. Balances flexibility and durability for daily use.

“We started with 0.05mm FPC for our smartwatch, but it tore during testing,” Alex said. “We switched to 0.1mm, and it lasted 10,000+ wrist bends—more than enough for a 2-year product life.”

Wearables need to be light—choose FPCs with thin copper layers (0.5oz vs. 1oz) and lightweight PI film. Avoid unnecessary reinforcements (like metal stiffeners) unless you need them for durability.

Raj’s team used 0.5oz copper FPC for their fitness band: “It cut the weight by 30% vs. 1oz copper. We didn’t need the extra thickness—0.5oz was more than enough for our low-power sensors.”

FPCs let you integrate features directly onto the circuit, instead of using separate components. For example:

- Print charging coils onto the FPC (no need for a separate coil).

- Add small sensors (like temperature sensors) directly to the FPC.

“We printed the charging coil onto our smartwatch’s FPC,” Alex said. “It saved us from adding a bulky separate coil—we used that space for a bigger battery.”

Let’s look at how a small wearable startup transformed their fitness tracker using FPCs. They had a prototype with a rigid PCB that was 8mm thick, weighed 30g, and only lasted 5 days on a charge. Here’s how FPCs fixed it:

- Rigid PCB forced the tracker to be thick and flat.

- Wasted space meant a small battery (5-day life).

- Heavy PCB made it uncomfortable to wear.

- Switch to 0.1mm FPC: Replaced the rigid PCB with a flexible one that curved with the tracker’s case.

- Integrate Charging Coil: Printed the coil onto the FPC, removing the need for a separate component.

- Wrap FPC Around Battery: Routed the FPC around the battery, freeing up space for a 30% larger battery.

- Thickness dropped from 8mm to 5mm.

- Weight fell from 30g to 18g.

- Battery life increased from 5 days to 8 days.

- Sales increased by 150% in the first 3 months.

“The FPC didn’t just improve the design—it made the product sellable,” said the startup’s CEO.

Our smartwatch design struggle taught us that traditional rigid PCBs are holding wearables back. FPCs don’t just fit into smaller spaces or curve around wrists—they let engineers create wearables that are comfortable, functional, and desirable.

As wearables get more advanced—think smart rings, skin patches, or even smart clothing—FPCs will become even more essential. They’re not just a component; they’re the key to breaking the “flat, bulky” mold of traditional electronics.

Next time you’re designing a wearable, ask yourself: “Can a rigid PCB do what we need?” If the answer is no (and it probably will be), it’s time to choose FPCs. Your users will thank you—they’ll barely notice the device on their body, but they’ll love what it does.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.