Date: 2026-01-26

If you're in the electronics manufacturing industry, you've certainly heard the term "PCB assembly" countless times. But what exactly does it involve? Let's break it down in plain language.

PCB Basics: The Foundation

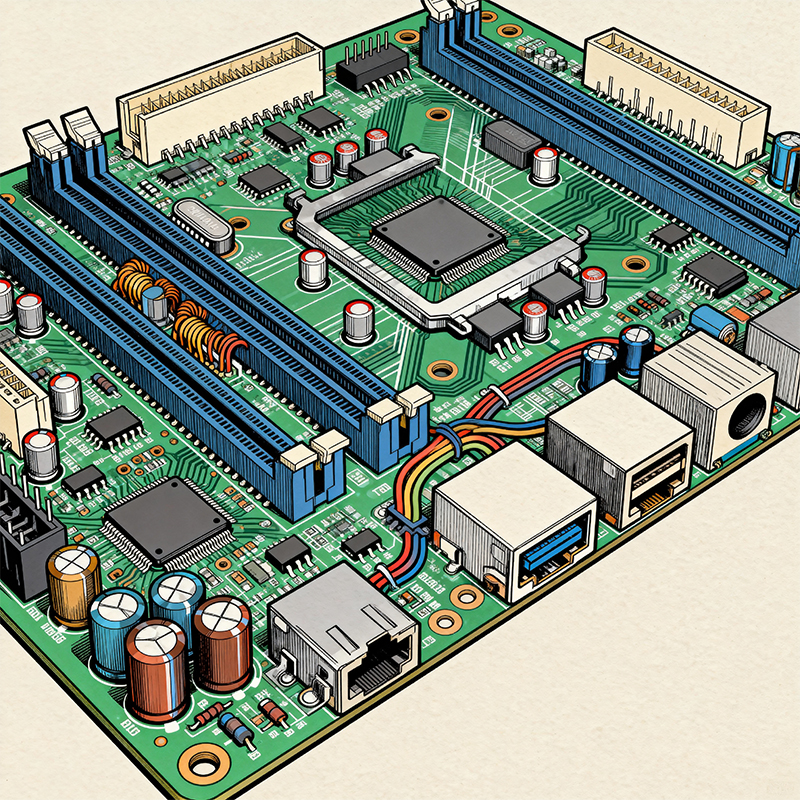

First, a PCB (Printed Circuit Board) is that green (or sometimes blue, red, or black) board you see inside virtually every electronic device. It's the platform that connects all the electronic components – think of it as the nervous system of your device.

The Assembly Process: Bringing Circuits to Life

PCB assembly is the process of attaching electronic components to that bare board. It's where that empty board transforms into a functional circuit that can power everything from smartphones to industrial machinery.

Here's how it typically works:

Solder Paste Application

Imagine spreading a thin layer of special "electronic glue" on the board. This solder paste (a mixture of tiny metal balls and flux) gets applied precisely where components will sit.

Component Placement

Next, pick-and-place machines (or sometimes skilled technicians) position resistors, capacitors, chips, and other components onto the prepared board. It's like a high-tech, ultra-precise version of setting up pieces on a game board.

The Soldering Process

The board then goes through a reflow oven – essentially a carefully controlled heating tunnel. The heat melts the solder paste, creating permanent electrical connections as it cools. For through-hole components, wave soldering or hand soldering might be used instead.

Inspection and Testing

After soldering, boards get checked. Automated optical inspection looks for alignment issues, while X-rays can check connections under chips. Functional testing ensures everything works as intended.

Final Cleaning and Protection

Boards are cleaned to remove any residue. Sometimes a protective coating is applied, especially for devices that might face moisture, dust, or extreme temperatures.

Why PCB Assembly Matters

For electronics manufacturers, understanding PCB assembly helps with:

Better design decisions

More reliable product planning

Informed supply chain choices

Effective quality control

Common Assembly Types

Surface Mount Technology (SMT): Components sit directly on the board surface – most modern electronics use this.

Through-Hole Technology (THT): Components have wires that go through holes in the board – often used for larger or more robust parts.

Mixed Technology: Many boards use both SMT and THT components.

Everyday Applications

From the phone in your pocket to the car in your driveway, from medical equipment to smart home devices – nearly every electronic product relies on professionally assembled PCBs.

The next time you use any electronic device, remember there's a carefully assembled PCB inside, making it all possible through this precise, fascinating manufacturing process.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..