Imagine a satellite orbiting 400 kilometers above Earth—its internal FPC (Flexible Printed Circuit) fails because it couldn’t handle the extreme cold of space. Or a fighter jet’s navigation system shuts down mid-flight, all because a PCB (Printed Circuit Board) solder joint cracked under vibration. In aerospace, these aren’t just product defects—they’re catastrophic failures that risk lives, destroy multi-million-dollar equipment, and derail critical missions.

Unlike consumer electronics (where a phone dying is a minor annoyance), aerospace devices operate in environments no other technology faces. That’s why FPCs and PCBs for planes, rockets, and satellites can’t follow the same standards as those in your AirPods or laptop. They need rules that prioritize survivability, consistency, and zero tolerance for flaws. Let’s break down the 4 key reasons aerospace demands special manufacturing standards.

Consumer electronics live in mild conditions: pockets, desks, rooms with controlled temperatures. Aerospace electronics? They face hellish extremes:

-

Extreme Temperatures: A satellite’s FPCs swing between -180°C (in Earth’s shadow) and 120°C (in direct sunlight)—far beyond the -40°C to 85°C range consumer FPCs handle. If the FPC’s insulation cracks in the cold, the satellite loses power.

-

Vacuum & Radiation: In space, there’s no air to cool PCBs—heat builds up fast. Radiation also damages PCB materials: a single cosmic ray can fry a circuit trace, causing a navigation error. NASA once lost a small satellite because its PCB wasn’t radiation-shielded.

-

Intense Vibration & Shock: During a rocket launch, PCBs endure vibrations 10x stronger than a car crash. A loose solder joint (common in low-standard PCBs) would snap instantly, shutting down the rocket’s guidance system.

Aerospace standards (like NASA’s NASA-STD-8739.4) force manufacturers to use heat-resistant materials (e.g., polyimide for FPCs) and test PCBs in vacuum chambers—something consumer electronics never require.

If your laptop’s PCB fails, you send it to a repair shop. If a Mars rover’s FPC fails? It’s 55 million kilometers from Earth—there’s no way to fix it. Aerospace devices are "mission-critical": they work once, or the mission fails.

Take the James Webb Space Telescope: its PCBs had to survive a 30-day journey to space and 10+ years of operation without maintenance. To ensure this, manufacturers followed IPC-A-610 Space Addendum—a standard that requires 100% inspection of every solder joint (consumer PCBs only need 10-20% inspection). A single missed flaw (like a tiny bubble in solder) could have blinded the telescope forever.

This "zero-failure" mindset means aerospace FPCs/PCBs cost 5-10x more than consumer versions—but the cost of failure (e.g., a $2 billion satellite crashing) is infinitely higher.

Your smartphone’s PCB lasts 2-3 years before you upgrade. Aerospace PCBs? They need to work for decades:

-

A commercial airplane’s avionics PCBs must last 20+ years, through 100,000+ flights.

-

A military drone’s FPCs need to survive 15 years of exposure to dust, humidity, and fuel vapors.

Consumer PCBs use cheap materials (e.g., epoxy resins that degrade over time) to cut costs. Aerospace PCBs use high-grade materials like PTFE (Teflon) for insulation—materials that resist aging, corrosion, and chemical damage. For example, Boeing’s 787 Dreamliner uses PCBs with PTFE insulation; these PCBs have a projected lifespan of 25 years, with no signs of degradation.

Aerospace standards also mandate "life-cycle testing": PCBs are exposed to simulated 20-year wear (temperature cycles, vibration) before they’re approved. Consumer PCBs never undergo this—they’re designed to be replaced, not retained.

Every aerospace device is regulated by strict agencies: NASA for space missions, the FAA (Federal Aviation Administration) for planes, and the DoD (Department of Defense) for military gear. These agencies don’t just set standards—they audit manufacturers to ensure compliance.

For example, the FAA requires airplane PCBs to meet RTCA DO-254: a standard that tracks every step of PCB production (from material sourcing to testing) with detailed documentation. If a manufacturer can’t prove a PCB’s copper traces meet a specific thickness, the FAA rejects the entire batch.

Why? Because a faulty PCB in a plane’s landing gear system could cause a crash. In 2018, a small aircraft crashed because its PCB (made to consumer standards) overheated—killing both passengers. Since then, the FAA has tightened rules to ban consumer-grade FPCs/PCBs in critical avionics.

Aerospace FPC/PCB standards aren’t just "strict"—they’re a necessity. They’re designed to tackle the unique horrors of space, the irreversibility of missions, the demand for decades-long durability, and the responsibility to protect lives.

Next time you look at a satellite image or fly on a plane, remember: the tiny FPCs and PCBs inside didn’t just "work"—they survived conditions no consumer tech could handle, all because of standards that refuse to accept "good enough." For aerospace, that’s not just quality assurance—it’s mission assurance.

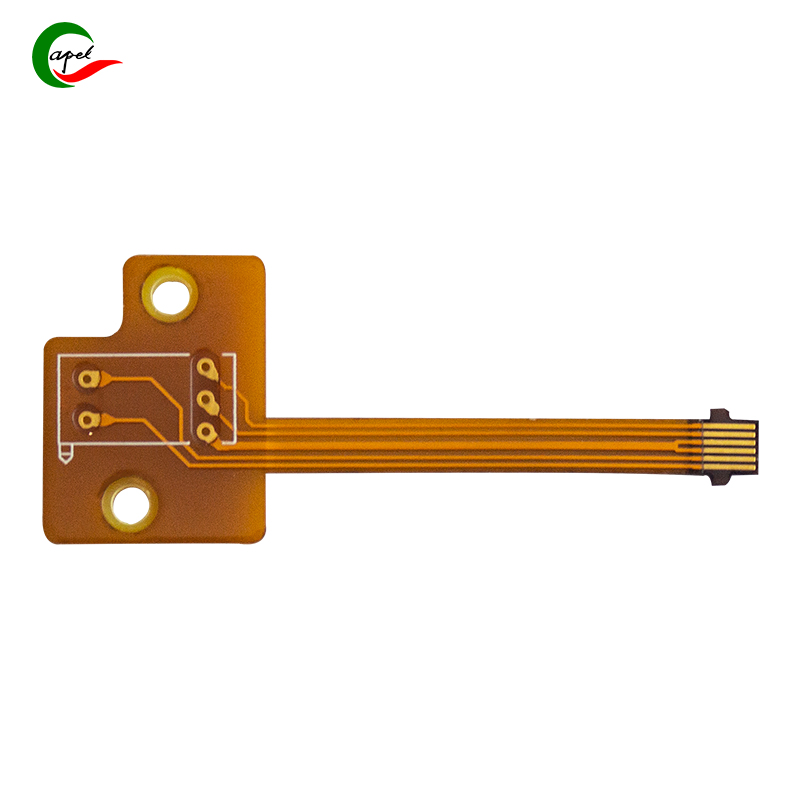

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.