Date: 2025-07-10

The GPS smartwatch industry has experienced significant growth and popularity worldwide in recent years. As a circuit board engineer working in the GPS smartwatch or smartwatch GPS tracker industry, it is fascinating to see how these wearable devices evolve to meet the diverse personal needs of consumers around the world. By focusing on the complex technical components within these devices, such as the GPS smartwatch printed circuit board (PCB), we can gain insight into how these components play a key role in enhancing the functionality and value of a GPS smartwatch. This article will explore the impact of GPS Smart Watch PCBs on meeting diverse personal needs while adding substantial value to market products.

A. The basis of technological innovation

PCB design and functionality

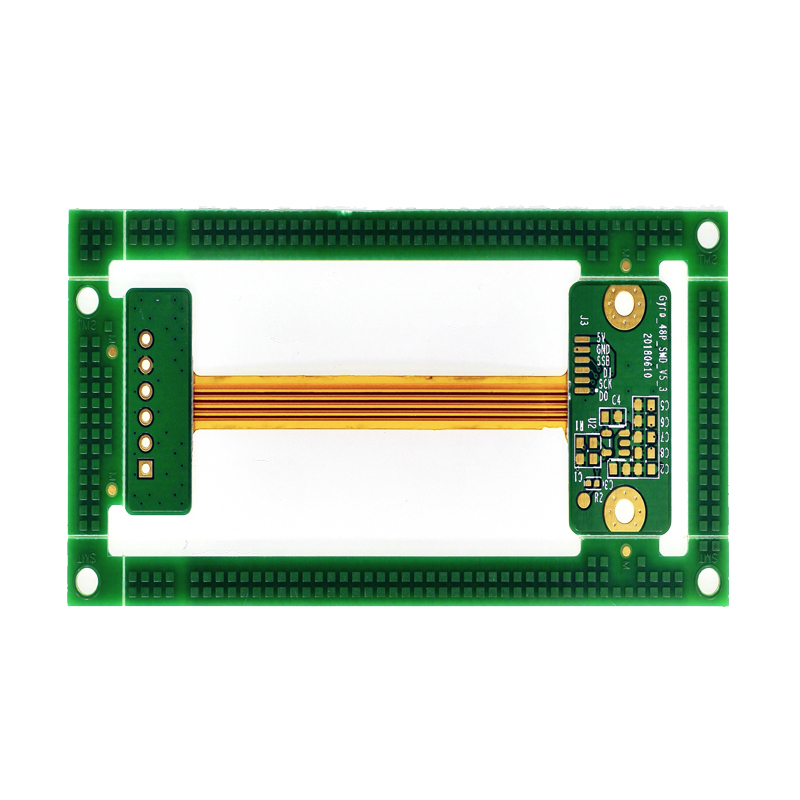

As a circuit board engineer, it is crucial to understand the basic role of PCB in a GPS smartwatch. These complex circuit boards are the backbone of technological innovation and provide the necessary platform for integrating various electronic components. The design and functionality of a tracker PCB circuit board must meet the requirements for GPS tracking, wireless communications, and sensor integration to ensure seamless functionality.

Miniaturization and space optimization

The development of the 4G GPS Tracker Circuit Board has been marked by significant advances in miniaturization and space optimization. As consumer demand for stylish, lightweight smartwatches continues to grow, circuit board engineers are tasked with developing PCBs that are not only compact but also capable of housing a range of functions on a single board, including GPS, cellular connectivity, heart rate monitoring, and more.

B. Enhance functional capabilities

GPS tracking accuracy and reliability

GPS functionality is the cornerstone of modern smartwatches, allowing users to track their location, monitor outdoor activities, and ensure personal safety. The integration of a GPS module into a smartwatch PCB requires precise design and layout considerations to ensure optimal signal reception, accuracy, and energy efficiency. As a circuit board engineer, the responsibility of fine-tuning PCB designs to enhance GPS tracking capabilities is an integral aspect of meeting the needs of individuals around the world.

Sensor integration for health and activity tracking

In the context of GSM GPRS GPS PCB boards, the integration of health and activity-tracking sensors becomes critical. From heart rate monitoring to step counting and sleep analysis, circuit board engineers play a key role in seamlessly integrating sensor technology into PCB layout. This integration not only helps meet personal health and fitness needs but also adds tremendous value to GPS smart watch products.

A. Cultural and geographical relevance

Localization and language support

One of the major challenges in the global smartwatch market is catering to different language and cultural preferences. Smartwatch PCBs help support multi-language displays and user interfaces, ensuring that individuals from different regions and backgrounds can access and use GPS smartwatches. As a circuit board engineer, the ability to facilitate localization through PCB design helps meet individual needs on a global scale.

Geographical mapping and navigation

From urban commuting to outdoor adventures, smartwatch GPS capabilities are indispensable to individuals around the world. By developing PCBs that optimize GPS signal reception and enable advanced mapping and navigation functions, engineers help improve the usability and reliability of GPS smartwatches to meet the diverse navigation needs of users in different geographical locations.

B. Customization and professional features

Customized features for specific groups of people

The versatility of GPS watch PCB designs enables the incorporation of specialized features to meet the needs of specific groups of people. For example, customizing the PCB layout to incorporate emergency SOS capabilities, child tracking capabilities, or elder care monitoring capabilities can meet the specific needs of different user groups. As a circuit board engineer, being able to adapt a PCB design to accommodate such specialized functionality can add significant value to the smartwatch product offered to consumers.

Power management and energy efficiency

Energy efficiency is a key issue for wearable devices, and the role of PCBs in managing power consumption cannot be overstated. Implementing optimized power management solutions and low-power design techniques in GPS Tracker PCBs can directly contribute to extending battery life and enhancing usability to meet the changing energy efficiency needs of users in different regions and environments.

A. Product differentiation and competitive advantage

Enhanced performance and reliability

Advanced PCB design in GPS smartwatches improves performance and reliability. By leveraging cutting-edge technologies such as multi-layer PCBs, high-frequency signal integrity optimization, and advanced component placement, circuit board engineers can enhance smartwatch functionality and position the product as a high-performance product in a highly competitive market environment.

Future-proof through upgradability

As technology continues to evolve, the importance of future-proof smartwatch products cannot be ignored. PCB engineers play a strategic role in developing scalable designs that seamlessly integrate new functionality and features through firmware updates or hardware expansions. This forward-thinking approach adds tremendous value to GPS smartwatch products by ensuring longevity and adaptability in the face of technological advancements.

B. Quality Assurance and Regulatory Compliance

PCB Fabrication and Component Selection

The quality and reliability of PCB manufacturing and component selection directly affect the overall performance and longevity of the smartwatch product. As a circuit board engineer, adhering to industry-leading manufacturing standards and selecting high-quality components is crucial to ensuring that your GPS smartwatch motherboard contributes to the robustness and longevity of the final product.

Comply with global standards and regulations

Navigating complex global standards and regulations is a key aspect of smartwatch development. PCB designs must comply with regulatory requirements related to wireless communications, electromagnetic compatibility, and environmental sustainability, ensuring that GPS smartwatch products meet the necessary certifications and approvals for different markets. Compliance with these standards not only adds value but also enhances the trust and reliability of the product.

In conclusion, as a circuit board engineer in the GPS smartwatch or smart watch GPS tracker industry, the intricate role of PCB in meeting the needs of different individuals around the world and adding value to the product cannot be overemphasized. The continuous innovation and optimization of PCB design directly affects the functionality, localization, customization, and reliability of GPS smartwatches, ultimately shaping the user experience and market positioning of these wearable devices. By staying at the forefront of technological advancements and aligning PCB innovation with user-centric needs, engineers can push GPS smartwatch products to new heights that meet the unique needs of individuals across cultures, geographies, and demographic groups.

As the GPS smartwatch industry continues to evolve, strategic integration of advanced PCB technologies will play a key role in driving product differentiation, enhancing competitiveness, and promoting global adoption. A holistic approach to PCB design and development, including functional optimization, cultural relevance, customization, and compliance with quality and compliance standards, will help shape the future of GPS smartwatch products and their ability to meet the diverse personal needs of users around the world. By recognizing the critical role of GPS smartwatch PCBs, engineers can continue to innovate and raise the bar for wearable technology, ultimately enriching individuals’ lives and adding significant value to the products they create.

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..