Date: 2025-07-10

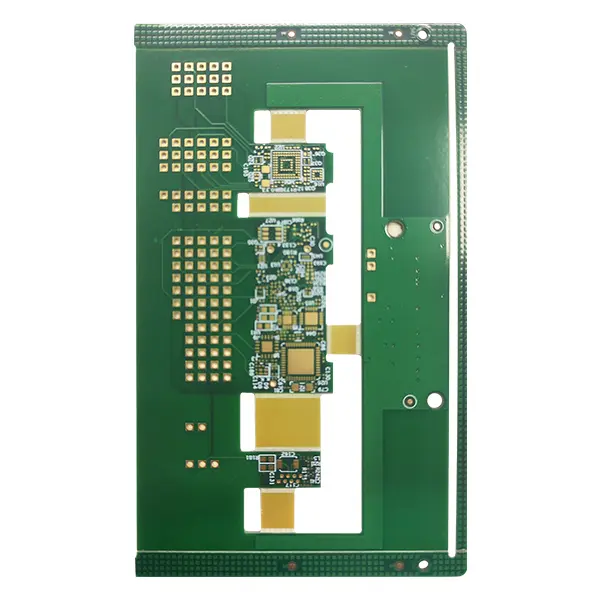

High-density interconnect printed circuit boards (HDI PCBs) have become an important innovation in the field of electronics, playing a key role in enhancing the functionality and performance of modern electronic devices.

In the digital age, electronic devices have become an integral part of our daily lives. From smartphones to smart home appliances, demand for advanced, compact and high-performance electronic products continues to grow. As the complexity of these products continues to increase, so does the need for advanced electronic components.

HDI PCBs are at the forefront of the electronics industry, driving the development of smaller, lighter, and more powerful devices. Their importance lies in their ability to accommodate increasing circuit density, optimize signal integrity, and contribute to the miniaturization of electronic products. As the demand for high-performance electronic devices continues to grow, the importance of HDI PCB as an enabling technology cannot be overstated.

HDI PCB is the abbreviation of High Density Interconnect PCB and represents the evolution of printed circuit board technology. It is designed to accommodate higher circuit density and finer lines and spaces, making it a necessity for modern electronic applications. There are many types of HDI PCBs, each type is tailored to meet specific design requirements and manufacturing capabilities.

Single Sided HDI PCB: This type of HDI PCB is designed with a single conductive layer on one side of the board, providing a cost-effective solution for space-constrained applications.

Double-sided HDI PCB: Double-sided HDI PCB uses two conductive layers to increase circuit density while maintaining a relatively compact form factor.

Single Layer HDI PCB: Single layer HDI PCB uses a single layer of conductive material and is suitable for applications requiring moderate circuit complexity.

Double-Layer HDI PCB: Double-layer HDI PCB has two conductive layers that provide enhanced routing capabilities and higher circuit density compared to single-layer PCB.

Multilayer HDI PCB: Multilayer HDI PCB uses multiple conductive layers and is good at accommodating complex circuits and high-density interconnections, making it ideal for cutting-edge electronic devices.

Advantages of HDI PCB: HDI PCB technology offers several advantages that help shape the electronics industry and drive innovation. These advantages include:

A. Increased circuit density: HDI PCB allows the integration of a greater number of components and interconnections in a smaller area, enabling the development of compact and feature-rich electronic products.

B. Improve signal integrity: By minimizing signal interference and transmission loss, HDI PCB helps maintain the integrity of high-frequency signals, ensuring reliable performance of advanced electronic systems.

C. Reduced size and weight: The compact design and high-density interconnection of HDI PCBs enable the development of thin and light electronic devices, meeting the growing demand for portable and space-saving solutions.

D. Enhanced electrical performance: The advanced design and manufacturing technology used in HDI PCB enhances electrical characteristics, including impedance control and power distribution, thereby improving overall performance.

E. Higher Reliability and Lower Cost: By optimizing signal paths and reducing bugs, HDI PCB provides higher reliability, while its compact size and efficient use of materials help save costs during the manufacturing process.

Capel Capel is a recognized leader in HDI PCB design, prototyping and manufacturing with over 15 years of experience in providing cutting-edge solutions to the electronics industry. With a focus on innovation and customer satisfaction, Capel has become a trusted partner for businesses seeking high-quality HDI PCB solutions customized to their specific requirements.

A. 15 years of HDI PCB design, prototyping and manufacturing experience: Capel’s extensive experience in HDI PCB design and manufacturing has made the company a key player in the electronic components industry. Through years of dedicated research and development, Capel continues to develop its capabilities to comply with the latest technological advancements and industry standards.

B. Range of HDI PCB products offered: Capel offers comprehensive HDI PCB solutions to meet different application needs, including:

1-40 Layer HDI PCBs: Capel has expertise in producing 1 to 40 layer HDI PCBs, enabling customers to take advantage of advanced circuitry and interconnect capabilities for complex electronic design needs.

1-30 HDI Flexible PCB: Flexible HDI PCB from Capel combines the advantages of high-density interconnect with flexibility to provide a versatile solution for applications requiring bendable and compact form factors.

2-32 HDI rigid-flexible PCB: Capel’s rigid-flexible HDI PCB integrates the advantages of rigid and flexible substrates, enabling the development of innovative electronic products with enhanced design flexibility and reliability.

C. Commitment to Quality and Customer Satisfaction: Capel’s unwavering commitment to delivering high-quality HDI PCBs and meeting customer needs makes it a reliable partner for businesses looking for top-notch electronic component solutions

All in all, the importance of HDI PCBs in shaping the modern electronics landscape cannot be overstated. Capel’s deep expertise and diverse product offerings in HDI PCB technology make it a leading partner for businesses looking for cutting-edge capabilities and dedicated support in PCB design and manufacturing. We encourage readers to explore the many benefits of HDI PCBs and consider Capel a trusted partner for their PCB needs.

Incorporating the latest advances in HDI PCB technology, Capel is ready to provide innovative solutions to businesses across industries, driving progress and shaping the future of electronic product development.

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..