Kaboer’s Double-Sided Flexible PCB for Displays is tailor-made for core display components such as smart wearable screens, automotive infotainment display modules, portable medical monitor display units, and IoT smart terminal displays. It precisely meets the core demands of display scenarios—ultra-thin flexible adaptation, distortion-free high-definition signal transmission, compact integration, and long-term reliable durability. With a cost-effective configuration of "1mil immersion gold finish + refined wiring", it stands as a preferred solution for display products across consumer electronics, automotive, medical, and other sectors, empowering brands to create flagship display terminals with slim profiles, smooth imaging, and exceptional user experiences!

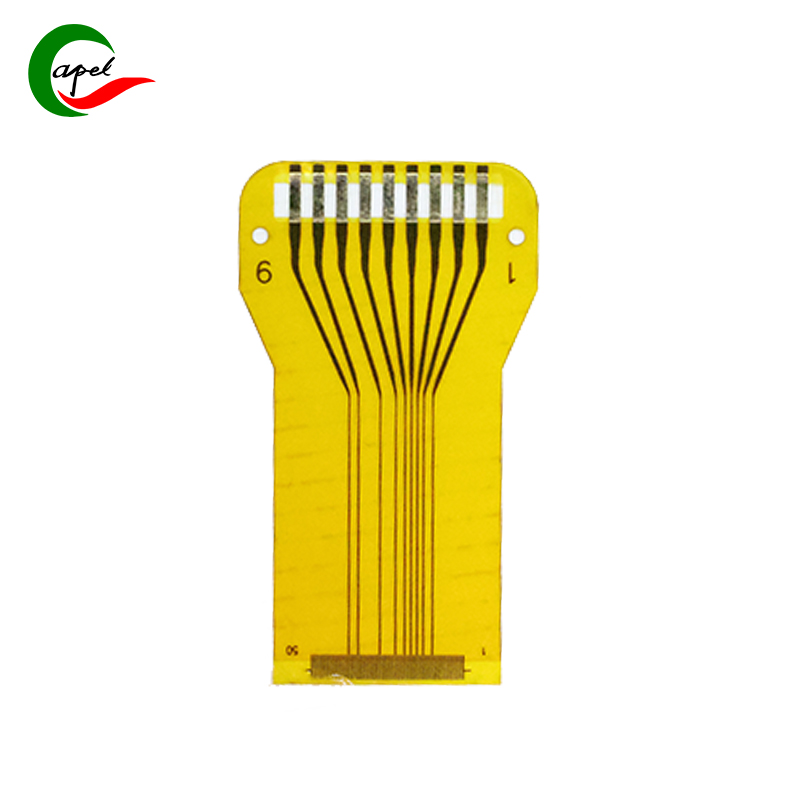

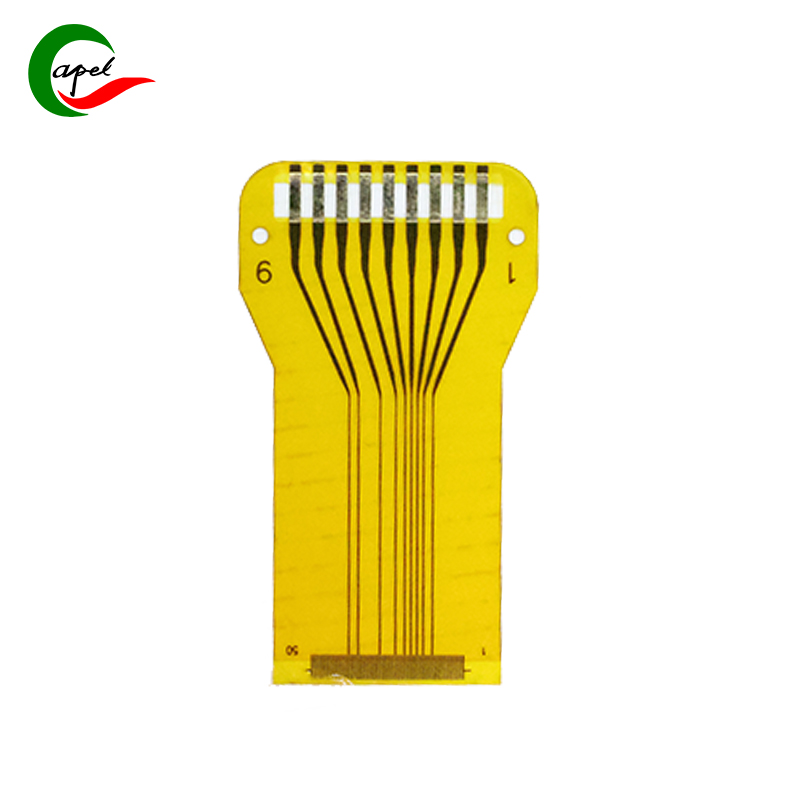

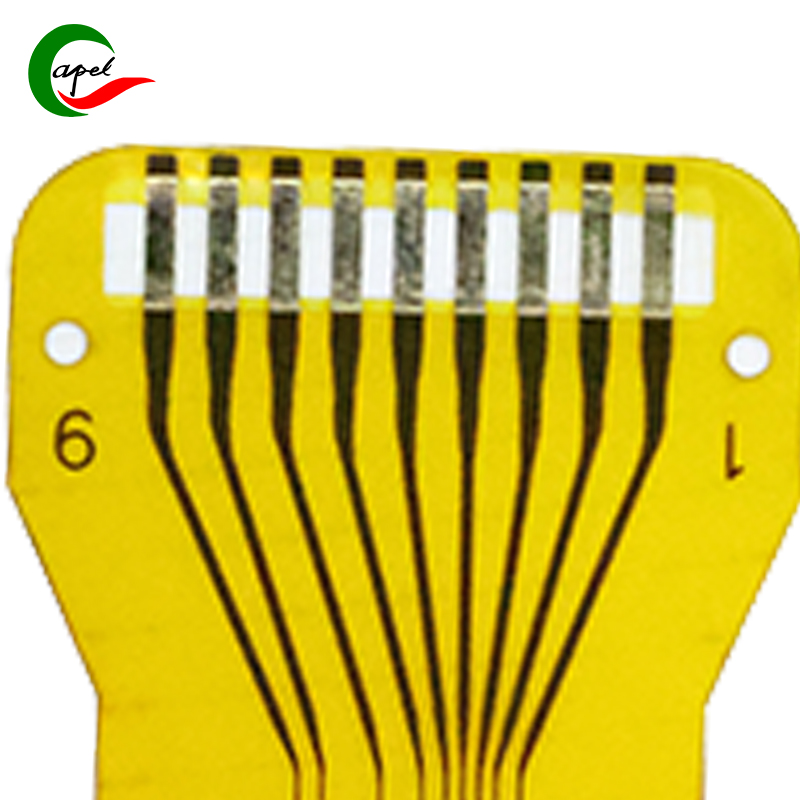

Featuring a double-sided flexible core structure, it perfectly balances the space constraints and operational reliability of display modules: at only 0.13mm thick, it is extremely slim with outstanding bending resilience, seamlessly fitting complex layouts such as curved screens, narrow bezels, and irregular-shaped displays. It adapts to the curved dials of smart watches, curved center consoles of automotive displays, and compact internal spaces of portable devices—completely solving the pain point of traditional rigid PCBs being unable to accommodate flexible display forms. With precise dimensions of 23.8*30mm, the compact layout perfectly matches the installation needs of small-to-medium display modules without redundant bulk; the 0.18/0.1mm fine line width/spacing and optimized 0.5mm drill size enable high-density signal channel integration and secure solder joint connections, efficiently carrying the transmission of multiple signal groups (e.g., pixel data, touch commands, backlight control) in limited space and providing solid circuit support for high resolution and high refresh rates of display panels.

Key advantages directly address display scenario pain points, delivering display-grade robust performance: ① Equipped with a 1mil immersion gold finish, it offers excellent conductivity, oxidation resistance, and wear resistance. Low contact resistance ensures high-speed, distortion-free transmission of high-definition display signals, eliminating issues such as image stuttering and touch lag. It also withstands plugging, unplugging, and friction during long-term use, extending product service life and adapting to high-frequency usage across multiple scenarios; ② Double-sided wiring design significantly improves space utilization and transmission efficiency, allowing flexible division of signal and control channels to effectively avoid crosstalk. It perfectly meets the dual needs of "high-definition display + precise touch control", while the immersion gold surface enhances soldering reliability, reducing module assembly defect rates and helping reduce costs and increase efficiency in mass production; ③ The flexible substrate boasts excellent wide-temperature adaptability (-40℃ to 85℃) as well as fatigue and vibration resistance. It can withstand long-term bending, environmental temperature changes, and automotive jolts in harsh scenarios, minimizing after-sales failure risks and aligning with the core demand of "low maintenance and high stability" for display products.

Backed by Kaboer’s profound technical expertise in flexible PCBs and strict quality control systems, this double-sided flexible PCB for displays can be customized for circuit layout, interface types, and contours based on display module resolution, installation methods, and functional requirements. Paired with rapid prototyping (sample delivery within 7 days) and efficient SMT assembly services, it helps customers shorten R&D cycles and accelerate time-to-market. Whether for ultra-slim smart wearable displays, reliable automotive screens, or high-precision medical display units, it serves as the "signal hub" of display modules with core advantages of "flexible adaptation, precise signal transmission, and stable durability", helping brands enhance product competitiveness and seize shares in the mid-to-high-end display market!