Kaboer’s Double-Sided Flexible PCB (General-Purpose) is tailor-made for small-to-medium electronic components, including core modules of smart wearables, circuit units of portable medical monitors, main control boards of IoT smart terminals, and auxiliary modules of automotive infotainment systems. It precisely addresses the core demands of multiple industries—ultra-thin flexible adaptation, stable signal transmission, multi-component integration, and long-term durability—with a highly adaptive configuration of "1mil immersion gold finish + double-sided scientific wiring". As a reliable preferred solution in consumer electronics, medical, automotive, and IoT sectors, it empowers enterprises to develop compact, high-performance, and low-failure products!

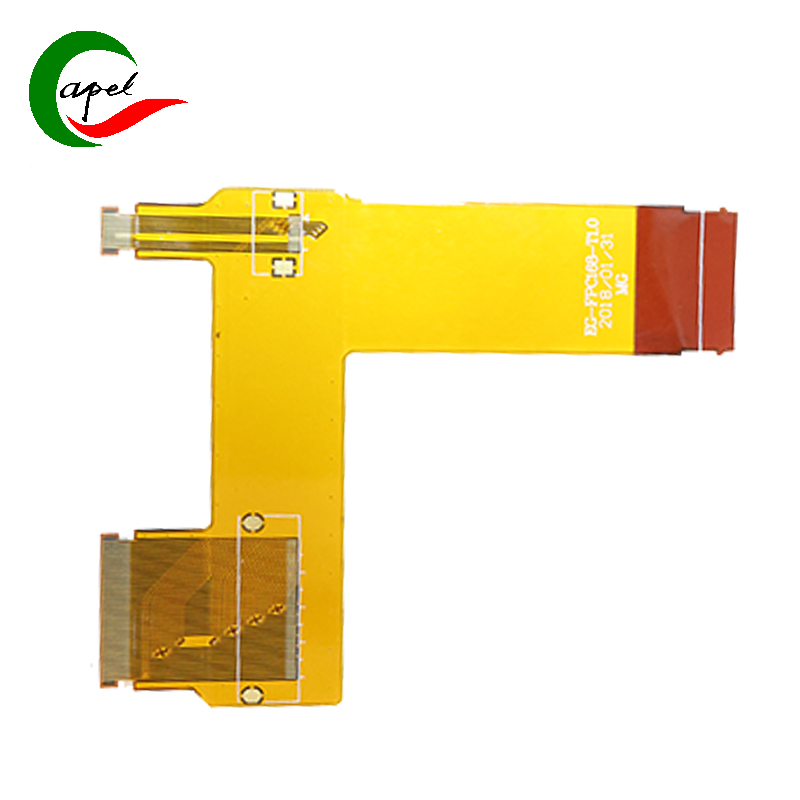

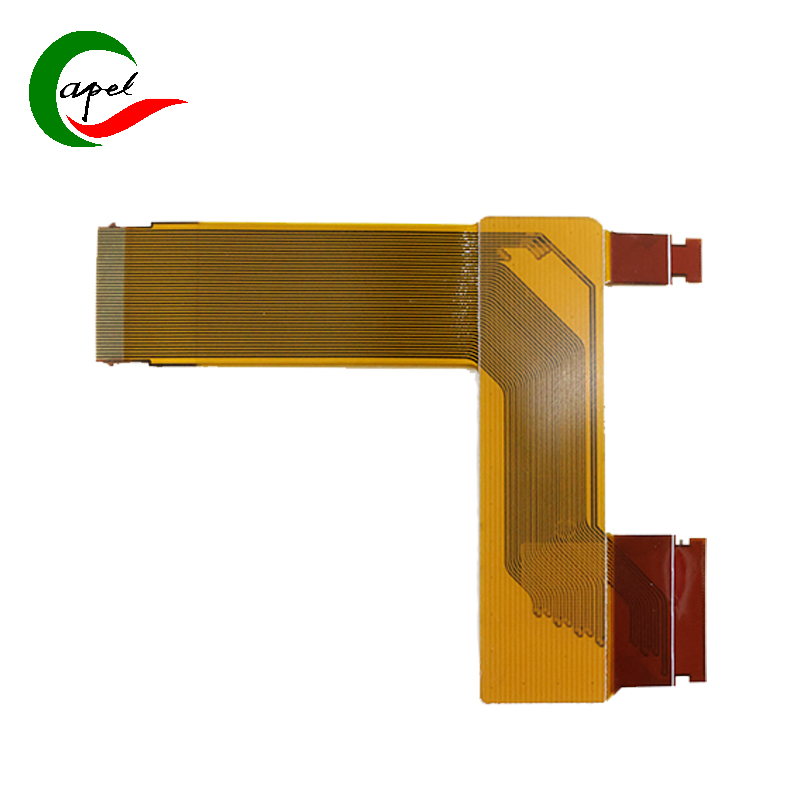

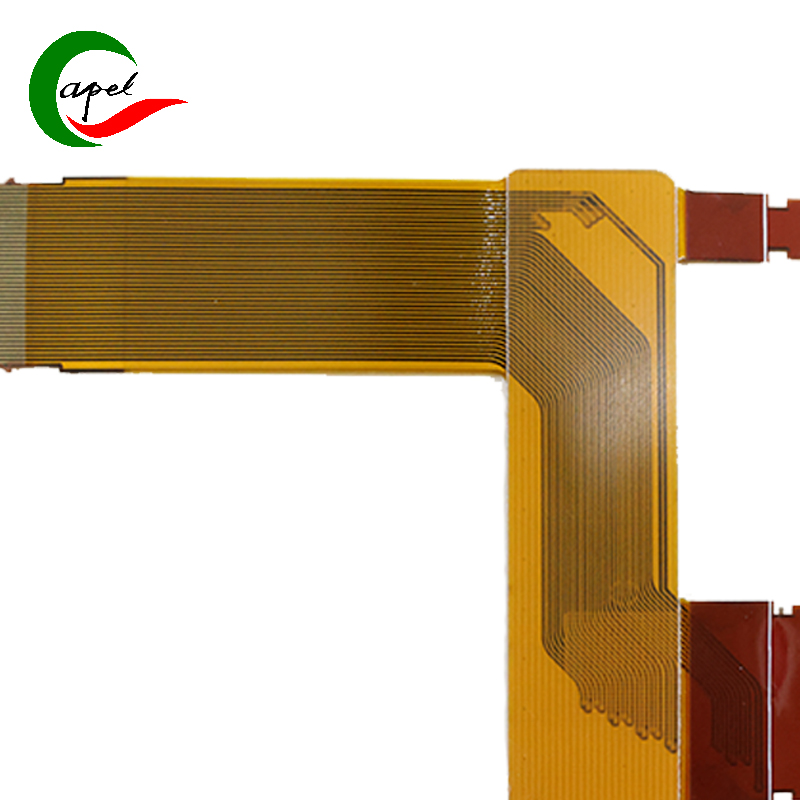

Featuring a double-sided flexible core structure, it perfectly balances the space constraints and operational reliability of multi-scenario devices: with an overall thickness of only 0.15mm, it is extremely slim and boasts excellent bending resilience, seamlessly fitting the curved surfaces of smart wearables, narrow cavities of portable medical devices, and complex layouts of automotive modules—completely solving the pain point of traditional rigid PCBs being unable to adapt to flexible installation scenarios; with precise dimensions of 74*91mm, the moderate board size supports multi-component integration (e.g., simultaneous layout of sensors, control chips, and data interfaces) without occupying redundant space, leaving ample room for device miniaturization; the 0.2/0.2mm equal line width/spacing ensures standardized wiring and stable signal transmission, while the double-sided layout enables separate transmission of "signal channels + power supply", reducing crosstalk risks and providing solid circuit support for efficient device operation.

Key advantages directly tackle pain points across industries, demonstrating general-purpose robustness: ① Equipped with 1mil immersion gold finish, it offers excellent oxidation resistance, wear resistance, and low contact resistance. It can withstand wiping with disinfectants like alcohol and hydrogen peroxide in medical scenarios, and resist high-temperature and high-humidity environments in automotive scenarios—effectively preventing signal interruptions caused by oxidation or poor contact and extending product service life; ② The double-sided wiring design increases space utilization by over 40%, allowing flexible circuit topology planning to meet the composite needs of "data collection + command control + power supply". Meanwhile, the immersion gold surface enhances soldering reliability, reducing module assembly defect rates and adapting to mass production rhythms; ③ The flexible substrate features wide-temperature resistance (-40℃ to 85℃) and excellent fatigue resistance, withstanding tens of thousands of bending cycles and environmental temperature changes. It maintains stability in scenarios such as frequent wearing of smart wearables, automotive jolts, and mobile use of portable devices, reducing after-sales failure risks.

Backed by Kaboer’s years of technical expertise in flexible PCBs and strict quality control systems, this double-sided flexible PCB can be customized for circuit layout, contour, and mounting holes based on device functional needs (e.g., interface type, signal transmission protocol, protection level). Paired with full-chain services including "1-30 layer FPC customization + rapid prototyping (7-day sample delivery) + efficient SMT assembly", it helps customers shorten R&D cycles and accelerate product launch. Whether for precise data transmission in smart wearables, reliable monitoring in portable medical devices, or stable control in automotive modules, it serves as the "core circuit hub" of devices with core advantages of "high adaptability, high stability, and high durability", helping enterprises reduce R&D costs, enhance product competitiveness, and gain an edge in multi-industry markets!