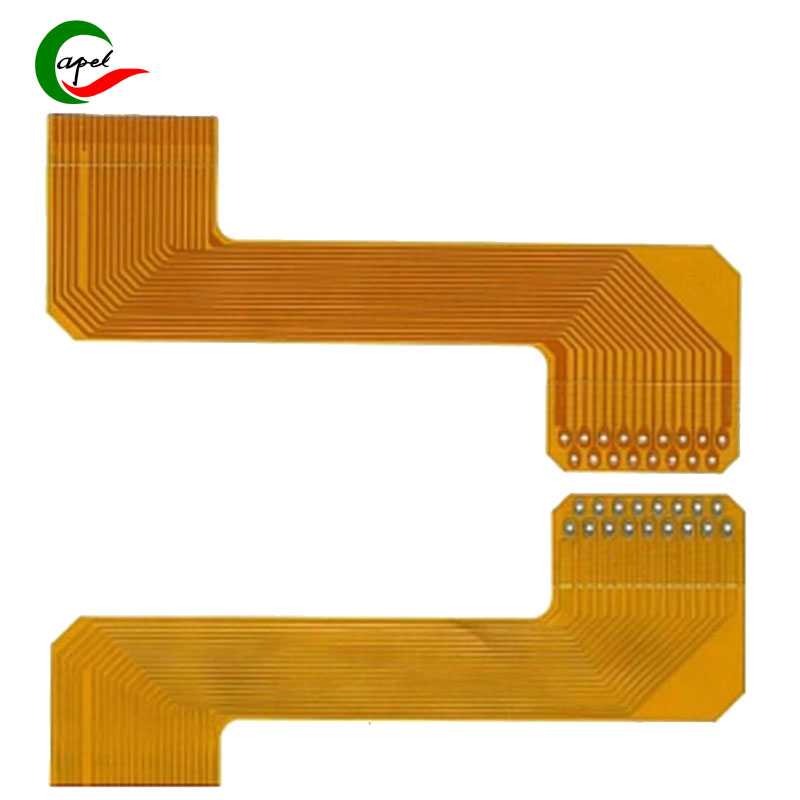

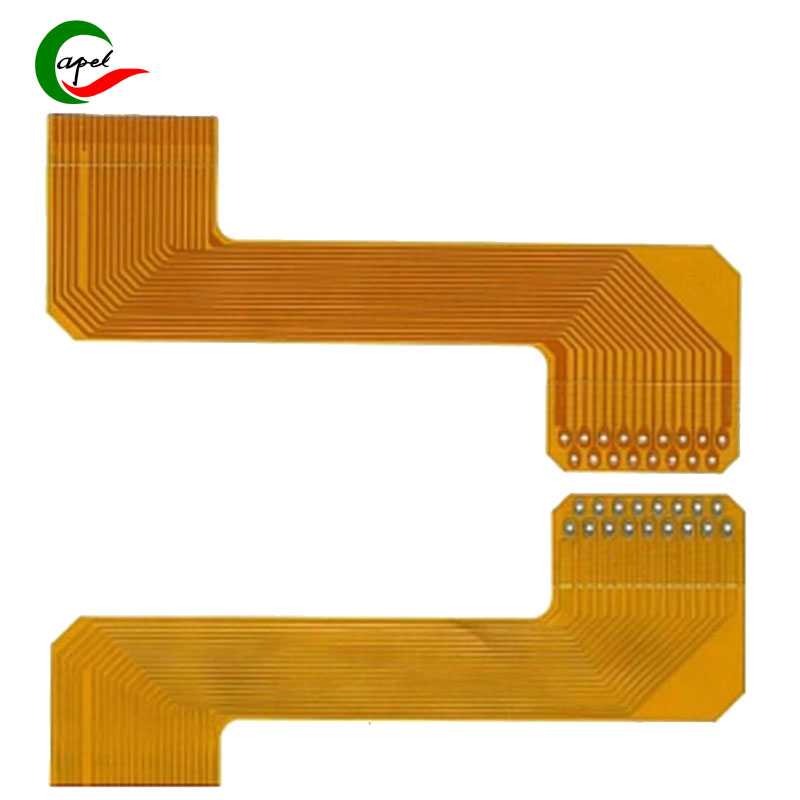

Automotive GPS Navigation FPC

A short introduction:

Type: Automotive GPS Navigation FPC

Minimum Line Width/Line Spacing: 0.07mm/0.06mm

Number of Layers: 2 Layers

Thickness: 0.15mm

Surface Finish: Immersion Gold 2 micro inches

Kaboer's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layer Rigid-Flexible Circuit Boards, 1-60 Layer Rigid PCB, Reliable Rapid turnaround PCB prototyping, rapid SMT PCB assembly

Industries We Serve:

Medical devices, IoT, TUT, drones, aerospace, automotive, telecom, consumer electronics, military, aerospace, industrial control, AI, electric vehicles, etc. ......

If you have related needs, please feel free to send us an email by clicking the button below.

Type: Flexible Circuit Boards (FPC) for automotive GPS navigation, specially designed for car navigation systems, with excellent flexibility and environmental resistance. Whether it is the internal signal connection of the embedded car navigation main unit or the wiring transmission between the center console and GPS module, it can be flexibly adapted to the complex installation space inside the car (e.g. behind the dashboard, under the center console) to realize the accurate transmission of satellite positioning signals, providing stable circuit support for real-time navigation, route planning, and Telematics. 99% of the FPCs are designed for car navigation, and they can be used in a wide range of applications, including car navigation, car navigation, and car navigation.

Minimum line width/spacing: 0.07mm/0.06mm high precision standard. This parameter is optimized for GPS high-frequency signal (L1 band 1575.42MHz): 0.07mm line width ensures lower loss of high-frequency signal transmission (attenuation rate ≤0.5dB/m), while 0.06mm line spacing realizes dense wiring in limited wiring space to support the parallel transmission of navigation signals and data communication signals, avoiding the interference between frequency bands, and guaranteeing real-time update of positioning data without delay. 99

Layers: 2-layer structural design to achieve fine signal management through scientific layering:

Signal layer: impedance matching design (target impedance 50Ω±10%) to optimize the transmission path of GPS satellite signals and reduce signal reflection and attenuation;

Ground layer: large copper foil covers to form an electromagnetic shielding barrier, which effectively isolates the signal from the environment; Ground layer: large copper foil covers to form an electromagnetic shielding barrier, which effectively isolates the signal from the environment. Ground layer: large copper foil cover forms electromagnetic shielding barrier, effectively isolating electromagnetic radiation from strong interference sources such as automobile engines, motors, radio frequency modules, etc., and ensuring the purity of weak GPS signals (receiving sensitivity ≤ -160dBm). The two-layer synergy significantly reduces the risk of signal crosstalk, which is especially suitable for automatic driving assistance scenarios (such as lane-level navigation) that require high positioning accuracy.99

Thickness: 0.15mm thin and light, perfectly adapted to the compact space requirements of automotive electronics. Under the trend of in-vehicle equipment integration (e.g., the integrated design of the center control screen and the instrument panel), it can significantly reduce the space occupied by the wiring and reserve a mounting position for other in-vehicle components (e.g., sensors, heat dissipation modules), and at the same time, improve the flexibility of bending during assembly (supporting the minimum bending radius R=1mm), so as to adapt to complex wiring paths inside the car.99

Surface treatment: Adopting the Immersion gold 2-micron-inch process (nickel layer thickness ≥5μm, gold layer thickness ≥0.05μm), bringing multiple automotive-grade advantages:

gold layer has excellent conductivity, reducing high-frequency signal transmission loss and ensuring that satellite signal reception sensitivity is increased by more than 10%;

2-micron-inch thickening of the gold layer significantly enhances the corrosion resistance, which can withstand oil, grease, dirt, and other contaminants in the car's interior, and can also be used in the automotive interior. Oil stains, temperature and humidity fluctuations (-40℃~+85℃) and other harsh environments (no corrosion after 2000 hours of salt spray test);

improves the reliability of soldering joints and ensures that the soldered parts of the wires, GPS modules and motherboards do not fall off during long-term vibration (10-2000Hz, 10g acceleration) and thermal cycling, prolonging the service life of the product (designed for the design). Enhance the reliability of solder joints to ensure that the soldered parts of the wires and GPS modules and motherboards do not fall off during long-term vibration (10-2000Hz, 10g acceleration) and thermal cycling, and prolong the service life of the products (design life ≥ 15 years / 200,000 km).

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..