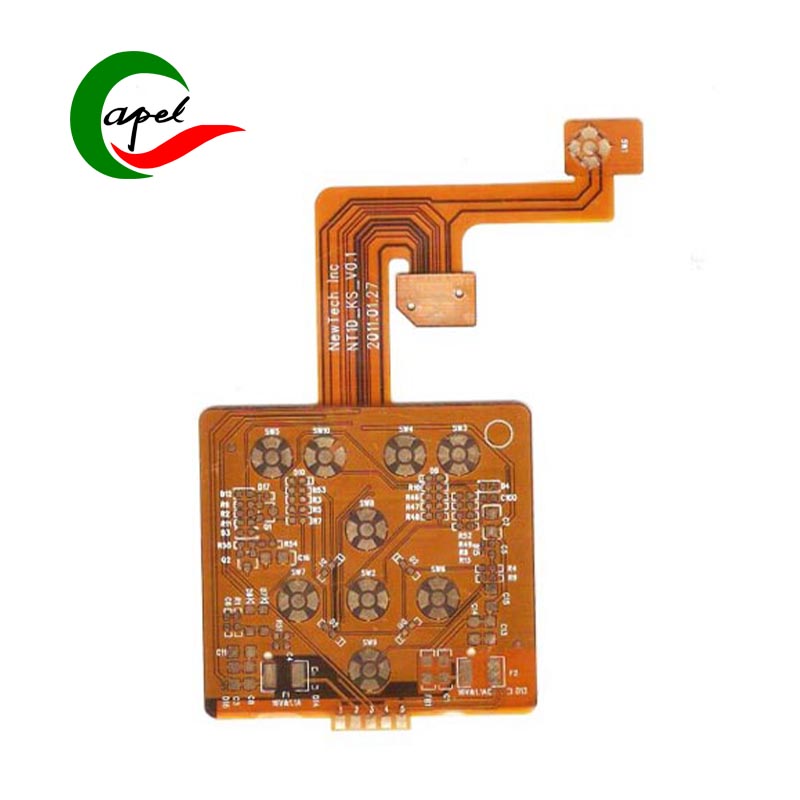

Medical Device Keypad FPC

A short introduction:

Type: Medical Device Keypad FPC

Minimum Line Width/Line Spacing: 0.076mm/0.076mm

Number of Layers: 2 Layers

Thickness: 0.1mm

Surface Finish: Immersion Gold 2 micro inches

Kaboer's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layers Rigid-Flexible Circuit Boards, 1-60 Layers Rigid PCB, Reliable and fast turnaround! PCB prototyping, rapid SMT PCB assembly

Industries we serve:

Medical devices, IoT, TUT, drones, aerospace, automotive, telecom, consumer electronics, military, aerospace, industrial control, AI, electric vehicles, etc. ......

If you have related needs, please feel free to send us an email by clicking the button below.

Type: Flexible Printed Circuit (FPC) for medical equipment keypad, designed for medical equipment keypad system, with excellent signal transmission stability and environmental resistance. Whether it is the parameter adjustment buttons for critical care monitors, rate control buttons for infusion pumps, or function switching buttons for surgical instruments, the FPCs can be flexibly adapted to the compact layout of the key modules (e.g., densely-packed key arrays, curved key panels) to realize real-time transmission of the key triggering signals, providing circuit support for the precise operation of medical personnel and avoiding medical risks due to delayed or incorrect triggering of the buttons.

Minimum line width/spacing: 0.076mm/0.076mm symmetry. This parameter is optimized for key signal characteristics: 0.076mm line width ensures that the weak electrical signals triggered by the keys (on-resistance change signals) have lower transmission loss (signal delay ≤ 10ms), reducing key response hysteresis; 0.076mm symmetrical line spacing realizes a dense independent wiring of the keys in a limited space (supporting the independent signal transmission of ≥ 20 keys in a single row), avoiding crosstalk between the keys (crosstalk rejection ratio ≥ 65%). (crosstalk suppression ratio ≥ 65dB), to ensure that “single-key triggering does not interfere with neighboring keys”, to eliminate the risk of misoperation.

Layers: 2-layer structure design, through scientific layering to achieve precise division of functions:

Signal layer: independent alignment design, each key corresponds to an exclusive signal path, reducing signal congestion when multiple keys are operated at the same time, and adapting to high-frequency operation scenarios (e.g., fast key response of first aid equipment);

Ground layer: a large-area copper foil covers the formation of a stable reference plane, shielding the equipment from internal power supply and electromagnetic interference of motors, ensuring that Ground layer: a large area of copper foil covers to form a stable reference plane, shielding the power supply and motor inside the equipment from electromagnetic interference, ensuring the purity of the key signal (low as mV level of on/off change signal), and avoiding false triggering (false triggering rate ≤ 0.1 times / 1000 operations).

The two-layer synergy not only ensures real-time signal transmission, but also strengthens the anti-interference ability, which is especially suitable for emergency equipment scenarios that require high operational precision.

Thickness: Only 0.1mm thin and light, perfectly suited for the miniaturization of medical equipment keypad modules. In portable medical equipment (such as handheld ultrasonic instruments, mobile monitors), can significantly reduce the impact of the key line on the thickness of the equipment (to help the thickness of the key module ≤ 3mm); in curved key panels (such as curved control panels), can enhance the flexibility of the line bending (support for the smallest bend radius R = 0.5mm), to ensure that the line is not stressed when the key is pressed to ensure that no damage to prolong the service life.

Surface treatment: the use of immersion gold 2 micro-inch process (nickel layer thickness ≥ 5μm, gold layer thickness ≥ 0.05μm), bringing multiple medical-grade advantages:

gold layer conductivity is stable, the contact resistance ≤ 5mΩ, reducing the key signal transmission loss, to ensure that the key triggered by the response time of ≤ 50ms, to achieve the “press that responds”;

2 micro-inch Thickened gold layer with excellent corrosion resistance, can withstand 75% alcohol, 0.5% povidone iodine frequent wiping (through the 3000 times disinfection wipe test without corrosion, no skinning), to adapt to the high-frequency daily disinfection of the use of the scenario;

high surface smoothness of the gold layer (Ra ≤ 0.05 μm), to reduce friction loss of the key contacts, to prolong the service life of the key (mechanical life of ≥ 100,000 presses), to reduce the frequency of maintenance of the device.

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..