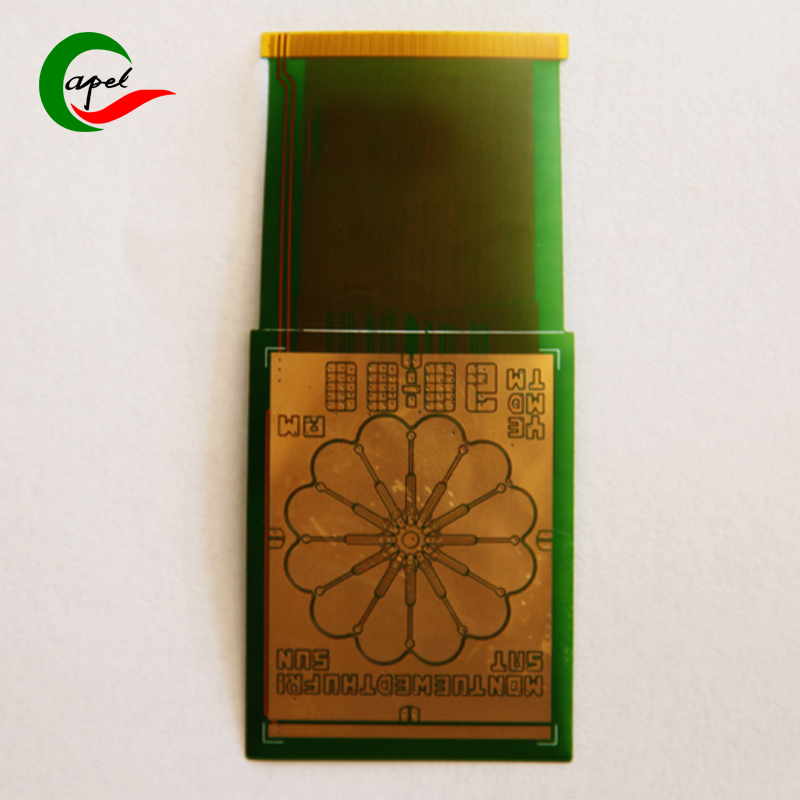

Consumer ETC Flexible Boards

A short introduction:

Type: Consumer ETC Flexible Boards

Minimum Line Width/Line Spacing: 0.3mm/0.2mm

Number of Layers: 2 Layers

Thickness: 0.1mm

Surface Finish: Immersion Gold 1 micro-inch

Kaboer's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layers Rigid-Flexible Circuit Boards, 1-60 Layers Rigid PCB, Reliable Fast Turnaround PCB Prototype Fabrication, Rapid SMT PCB Assembly

Industries We Serve:

Medical devices, IoT, TUT, UAVs, Aerospace, Automotive, Telecom, Consumer Electronics, Military, Aerospace, Industrial Controls, Artificial Intelligence, Electric Vehicles, etc. ......

If you have related needs, please feel free to send us an email by clicking the button below.

Type: Consumer ETC Flexible Circuit Board (FPC), designed for in-vehicle ETC devices, with excellent RF signal transmission performance and in-vehicle environment adaptability. Whether it is front windshield stick-on ETC, rearview mirror integrated OBU, or portable in-vehicle ETC devices, it can flexibly adapt to the compact space of in-vehicle installation (such as thin and light design with device thickness ≤8mm, curved mounting parts), realize efficient connection between RF module, main control chip and antenna, and guarantee the “second recognition, fast deduction” experience of high-speed toll booths. It can realize efficient connection between RF module, main control chip and antenna, guaranteeing “second identification, fast deduction” experience at high-speed toll stations, and avoiding delayed passage caused by signal interruption.

Minimum Line Width / Line Spacing: Reach the high precision standard of 0.3mm/0.2mm. This parameter is specially optimized for ETC RF signal characteristics: 0.3mm line width ensures lower transmission loss of 900MHz high-frequency signals (signal attenuation rate ≤ 0.3dB/m), reducing RF energy loss; 0.2mm line spacing realizes independent wiring of RF signals, power supply, and grounding lines in limited circuit space, avoiding crosstalk between different lines (RF signal isolation ≥ 60dB), guaranteeing signal purity and improving signal purity. It can guarantee the signal purity and improve the communication distance between toll station antenna and vehicle OBU (effective communication distance ≥10m).

Layers: 2-layer structural design, precise division of functions through scientific layering, solving the problem of interference between RF signals and DC circuits:

RF signal layer: adopting impedance matching design (target impedance 50Ω±10%), optimizing the RF signal transmission path, reducing the reflection of signals, ensuring that the signal VSWR of the 900MHz frequency band is ≤1.5, and enhancing the success rate of communication;

Grounding layer: a large-area copper foil covers the “RF ground plane”, ensuring signal purity and enhancing the communication distance between toll station antenna and vehicle OBU (effective communication distance ≥10m). Ground layer: large area copper foil covers to form “RF ground plane”, which not only serves as the reference plane of RF signal to enhance transmission stability, but also shields the electromagnetic interference of engine and motor in the vehicle environment (EMI suppression ≥ 50dB), especially suitable for the scene of close contact with automotive electronic equipment.

The two-layer synergy simplifies the circuit structure while safeguarding the RF performance, which is suitable for the miniaturization requirements of ETC equipment.

Thickness: 0.1mm, the ultimate thinness, perfectly suited to the consumer ETC “thin and light” design trend. In vehicle integration scenarios (e.g., rearview mirror built-in ETC), it can significantly reduce the occupancy of circuit components on the thickness of the device (helping the total thickness of the device ≤ 5mm); in curved mounting areas (e.g., curved front windshield edges), it can enhance the flexibility of bending (supporting the smallest bending radius R=0.5mm), adapting to the mounting angles of different car models, and avoiding stress damage to the wiring due to long-term bending.

Surface treatment: the use of immersed gold 1 micro-inch process (nickel layer thickness ≥ 3μm, gold layer thickness ≥ 0.025μm), to bring multiple vehicle-grade advantages:

excellent conductivity of the gold layer, reducing RF signal transmission loss, to ensure that the ETC equipment receiving sensitivity ≥ -85dBm, to enhance the success rate of the toll station signal recognition;

immersed gold plating layer of corrosion resistance, can withstand the car environment of the oil, vapor erosion (through the 48-hour neutral salt spray test without any). Strong corrosion resistance of the immersed gold plating layer, resistant to oil, water vapor erosion in the vehicle environment (through 48 hours of neutral salt spray test without corrosion), adapt to long-term exposure to high temperature and high humidity in the car (such as high temperature in the car after summer sun exposure);

to enhance the reliability of soldering joints to ensure that the RF module, the chip and the wiring of the welded parts of the longterm vibration (such as the bumpy road) without shedding, to extend the service life of the equipment (design life ≥ 5 years).

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..