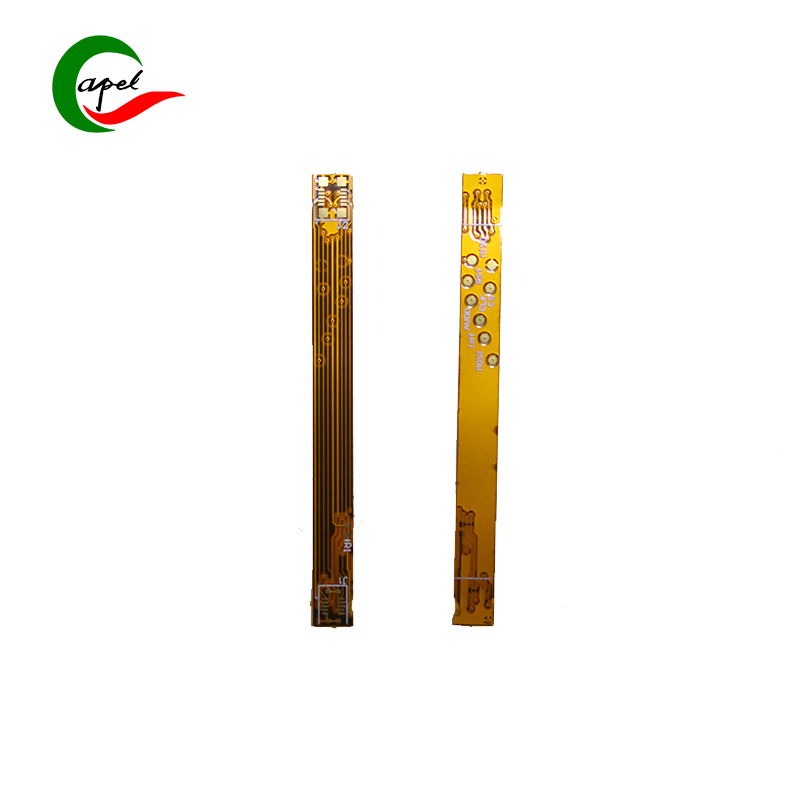

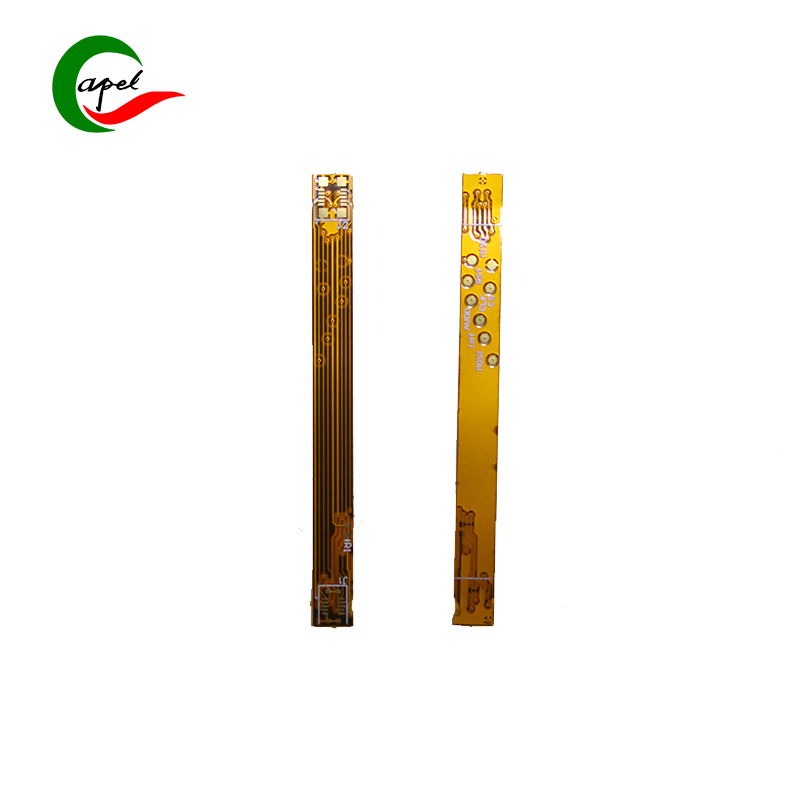

Kaboer’s Double-Sided Flexible PCB for Mobile Phones is tailor-made for core smartphone components such as touchscreen flex cables, camera modules, antenna connection assemblies, charging port interfaces, and display driver units. It precisely meets the core demands of mobile phones—ultra-slim design, high-density integration, stable high-frequency signal transmission, and bending durability. With the robust configuration of "Immersion Gold + Steel Foil with Impedance Control", it stands as a preferred performance solution for consumer electronics brands to create flagship models, empowering mobile phones to achieve slimmer bodies, more stable signals, and longer-lasting durability!

Adopting a double-sided flexible structure, it perfectly balances the space constraints and operational reliability of mobile phones: with an overall thickness of only 0.2mm, it is extremely slim and boasts exceptional bending toughness. It can flexibly fit curved structures, narrow cavities, and component connection gaps inside mobile phones, easily avoiding wiring interference and adapting to the compact layout needs of various smartphone forms (full-screen, foldable phones). It completely solves the limitations of traditional rigid PCBs—wiring restrictions and inability to fit complex curved surfaces. Backed by refined manufacturing standards, the 0.2/0.25mm line width/spacing and 0.2mm micro drill size enable high-density wiring and precise connections, integrating more functions in limited space and providing sufficient wiring support for complex smartphone features such as multi-camera systems, fast charging, and 5G communication.

Key advantages directly address mobile phone pain points, demonstrating flagship-level performance: ① Equipped with dual advantages of 1mil Immersion Gold and Steel Foil with Impedance Control, it offers superior low signal loss, oxidation resistance, and wear resistance. It precisely controls impedance stability, ensuring high-speed, distortion-free transmission of 5G RF signals, fast charging power signals, and high-definition display signals. This reduces signal attenuation and delay, delivering faster network speeds, more stable charging, and smoother screen display for mobile phones; ② Double-sided wiring design significantly improves space utilization and signal transmission efficiency, adapting to the collaborative work needs of multiple mobile phone components. Meanwhile, the immersion gold surface enhances soldering reliability, suitable for mass SMT assembly in consumer electronics and reducing assembly defect rates; ③ The flexible substrate features excellent fatigue resistance and wear resistance, withstanding slight deformations and plugging operations during daily mobile phone use. It extends component service life and reduces after-sales failure risks, meeting user expectations for "high-frequency use and long-term durability" of mobile phones.

Backed by Kaboer’s profound technical accumulation in consumer electronics PCBs and strict quality control system, this double-sided flexible PCB can be customized for impedance parameters, interface types, wiring routes, and other requirements based on mobile phone functional needs (e.g., foldable screen bending cycles, 5G band compatibility, fast charging power). Paired with rapid prototyping and efficient SMT assembly services, it helps customers shorten R&D cycles and accelerate time-to-market. Whether for flagship bar phones pursuing extreme slimness, foldable phones requiring high reliability, or mid-range models focusing on long battery life, it serves as the "core connection hub" of mobile phones with stable performance—helping brands enhance product competitiveness and seize the high-end consumer electronics market!