Kaboer’s Double-Sided Flexible PCB for Medical Diagnostic Device Display Panels is engineered specifically for display units of core medical equipment—including ultrasound machines, biochemical analyzers, portable diagnostic devices, and endoscope display modules. It precisely addresses the core demands of medical environments: distortion-free high-definition signal transmission, precise assembly compatibility, long-term reliability, and regulatory compliance. With a robust configuration of "medical-grade 1mil immersion gold finish + FR4 reinforcement", it stands as a trusted solution for medical device brands developing high-precision diagnostic products, empowering enhanced diagnostic efficiency and result accuracy!

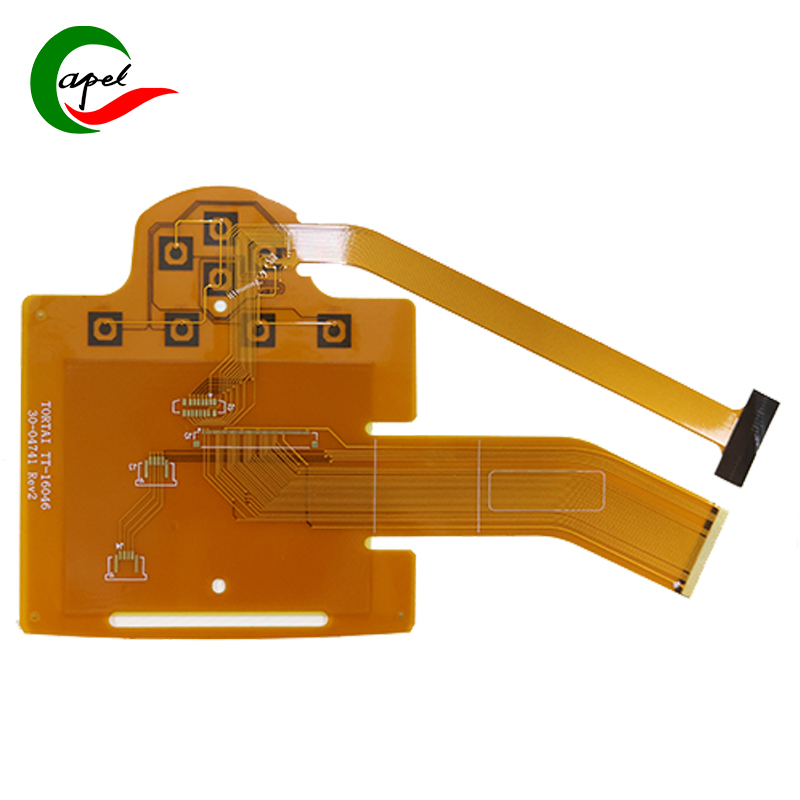

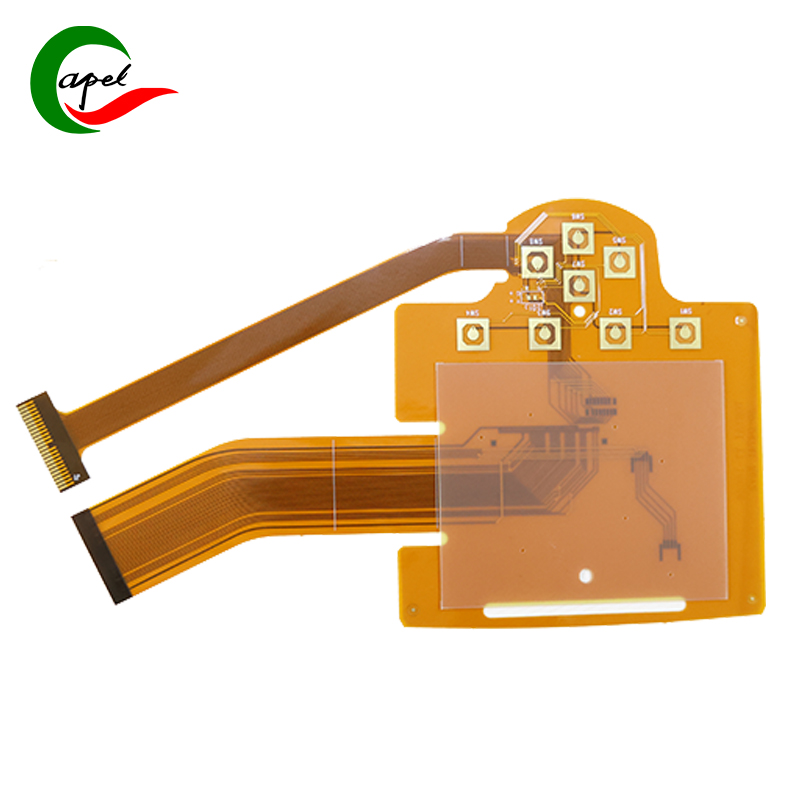

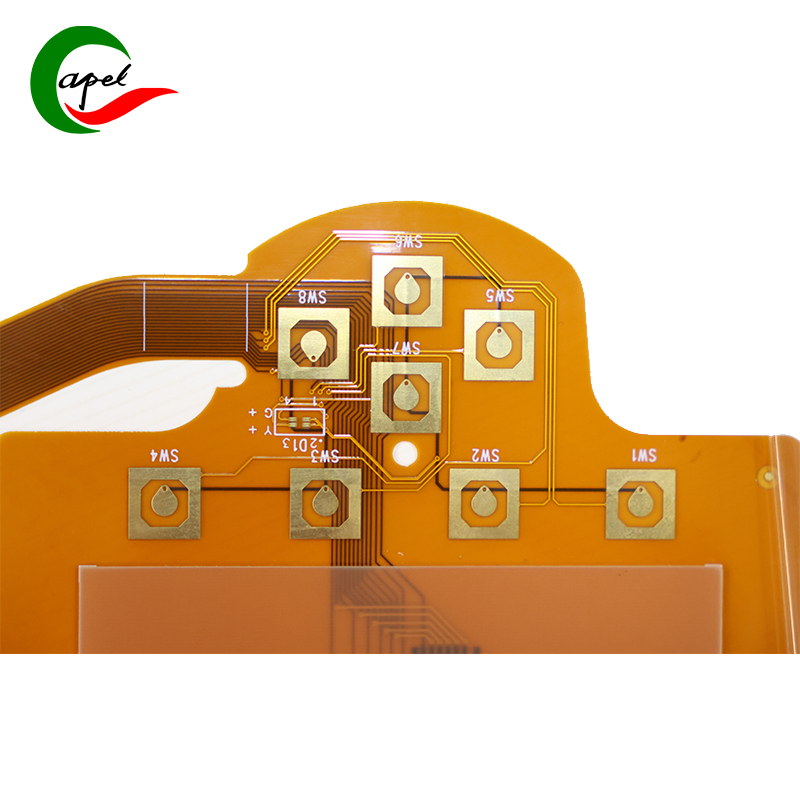

Featuring a double-sided flexible structure with localized FR4 reinforcement, it strikes the perfect balance between display panel adaptability and reliability: at only 0.23mm thick, the flexible substrate offers exceptional bending resilience, seamlessly conforming to the curved profiles, narrow installation cavities, and component connection gaps of medical diagnostic devices. It eliminates wiring interference, adapting to the compact layout requirements of both portable and benchtop diagnostic equipment; FR4 reinforcement in critical areas enhances mechanical strength without compromising flexibility, improving deformation resistance during assembly and solder joint stability—avoiding line damage caused by assembly operations and meeting the precision standards of medical device manufacturing. Built to rigorous production specifications, its 0.147/0.12mm ultra-fine line width/spacing and 0.2mm micro drill size enable high-density wiring and precise solder joint placement, accommodating the transmission of high-definition display signals (e.g., medical images, test data) in limited space and supporting the high resolution and refresh rates of medical display panels.

Key advantages directly tackle medical diagnostic pain points, delivering medical-grade performance: ① The combination of 1mil immersion gold finish and FR4 reinforcement ensures superior oxidation resistance, corrosion resistance, and tolerance to sterilization wipes (compatible with medical disinfectants such as alcohol and hydrogen peroxide). Low contact resistance guarantees high-speed, distortion-free transmission of high-definition display signals and control commands, eliminating blurred images and data errors caused by signal attenuation. FR4-reinforced zones boost pressure resistance and plug-in durability at interface locations, meeting the demands of long-term, high-frequency use in medical settings; ② Double-sided wiring maximizes space utilization and signal transmission efficiency, supporting flexible integration of display driver chips, touch control units, and data interfaces. It caters to the dual needs of "high-definition display + precise interaction" for medical panels, while the immersion gold surface enhances soldering reliability, reducing module assembly defects and aligning with the high-cleanliness production standards of the medical industry; ③ The flexible substrate complies with medical-grade biocompatibility requirements, boasting excellent wide-temperature performance (-40℃ to 85℃), strong aging resistance, and fatigue resistance. It endures long-term standby operation and frequent on-off cycles of medical equipment, minimizing after-sales risks and meeting the "low-maintenance, high-stability" core demand of medical environments.

Backed by Kaboer’s extensive experience in medical-grade PCB R&D and strict quality control systems, this double-sided flexible PCB adheres to ISO 10993 biocompatibility standards and is compatible with global medical regulations (FDA, CE, NMPA). It can be customized for circuit layout, reinforcement positions, and interface types based on display panel resolution, size, and installation requirements. Paired with rapid prototyping (sample delivery within 7 days) and efficient SMT assembly services, it helps customers shorten R&D cycles and accelerate product certification and market entry. Whether for high-definition imaging in ultrasound machines, data visualization in portable devices, or real-time display in endoscopes, it serves as the "signal backbone" of medical display panels—delivering precise transmission, stable durability, and regulatory compliance. It empowers enterprises to reduce compliance risks, enhance product credibility, and gain a competitive edge in the medical diagnostic equipment market!