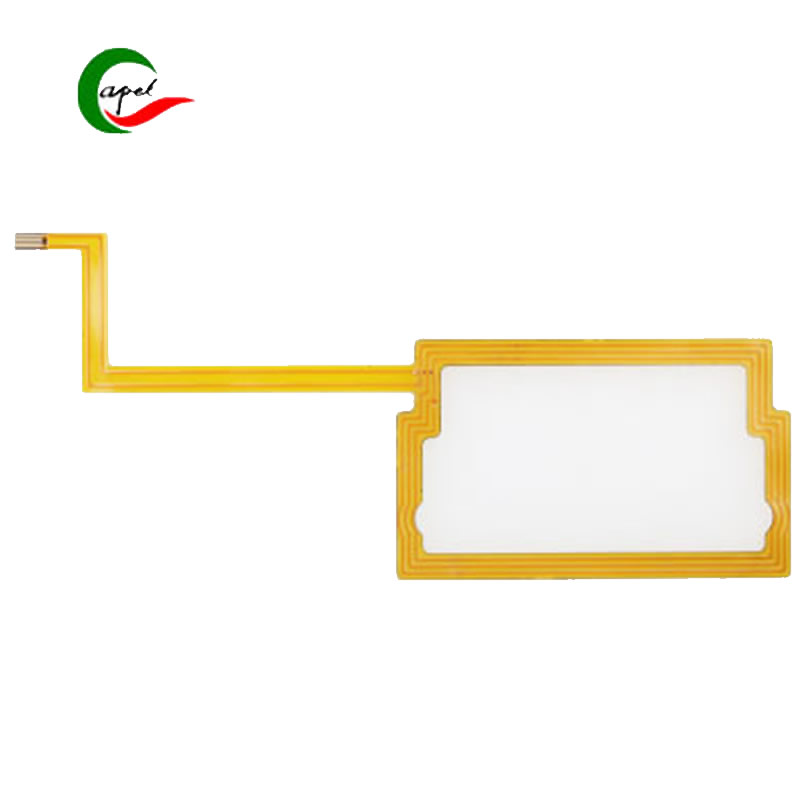

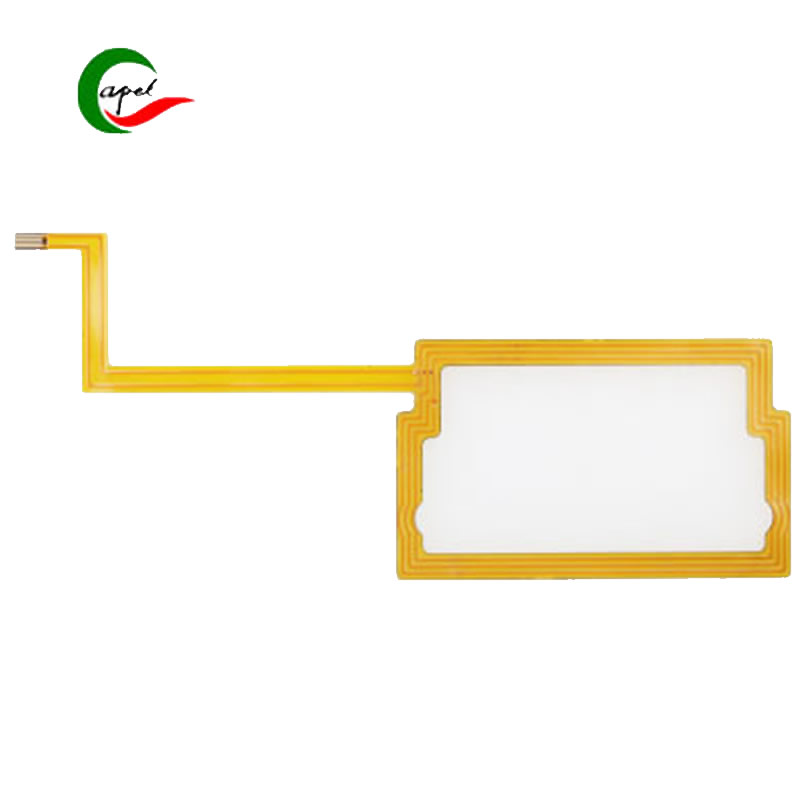

Tablet Antenna FPC

A short introduction:

Type: Tablet Antenna FPC

Minimum Line Width/Line Spacing: 0.3mm/0.2mm

Number of Layers: 2 Layers

Thickness: 0.12mm

Surface Finish: Immersion Gold

Kaboer's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layers Rigid-Flexible Circuit Boards, 1-60 Layers Rigid PCB, Reliable Quick Turn PCB Prototyping Rapid SMT PCB assembly.

Industries we serve:

Medical devices, IoT, TUT, UAVs, Aerospace, Automotive, Telecom, Consumer Electronics, Military, Aerospace, Industrial Controls, Artificial Intelligence, Electric Vehicles, etc. ......

If you have related needs, please feel free to send us an email by clicking the button below.

Type: Flexible Printed Circuit (FPC) for Tablet PC Antenna

Designed for tablet PC wireless communication module, it serves as the core carrier of antenna signal transmission and supports multi-band wireless technologies such as Wi-Fi 6E, Bluetooth 5.3, 5G NR, and so on. Its flexible characteristics allow the antenna to be flexibly laid out in the complex space inside the tablet, such as edge bending and laminating, and integrating multiple antenna arrays to optimize signal reception and radiation efficiency.

Minimum Line Width / Pitch: 0.3mm/0.2mm

This parameter balances high-frequency signal transmission with the difficulty of production process:

0.3mm line width ensures sufficient current carrying capacity and reduces signal transmission loss (especially in the high-frequency band of 2.4GHz/5GHz);

0.2mm line spacing meets the need for high-density cabling and supports multi-antenna integration design (e.g. multi-channel layout for MIMO technology).

Layers: 2-layer structure

Signal layer: Differential alignment design to reduce EMI and optimize high-frequency signal integrity;

Ground layer: Large-area copper foil grounding to provide a stable reference plane and enhance antenna radiation efficiency.

Thickness: 0.12mm

Advantages of ultra-thin design:

Reduce the space occupied by the antenna module, adapt to the trend of thin and light tablet PCs (e.g. Apple iPad Air thickness 6.1mm);

Enhance the flexibility of bending, support ≥ 5000 times of dynamic bending (to meet the tablet frequent opening and closing of the use of the scenario). 3.

Surface treatment process

immersion gold (ENIG):

nickel layer (thickness ≥ 3μm): block copper migration, improve the reliability of the solder joints;

gold layer (thickness ≥ 0.05μm):

excellent conductivity to reduce the signal attenuation (less skin effect at high frequencies);

anti-sulfur / oxidation characteristics, adapt to high temperature and high humidity environment (such as Southeast Asia market demand).

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..