Kaboer’s 4-Layer Rigid-Flex Board for Communication Equipment is tailor-made for lightweight communication products such as small IoT gateways, portable communication terminals, vehicle-mounted communication modules, and micro base station components. It precisely meets the core demands of communication scenarios—stable high-frequency signal transmission, ultra-compact adaptation, low-power long standby, and strong anti-interference capability. With the core advantages of "thin, light, tough + high-density integration", it stands out as a performance benchmark for small communication equipment R&D, empowering brands to quickly break through in the IoT and automotive communication tracks!

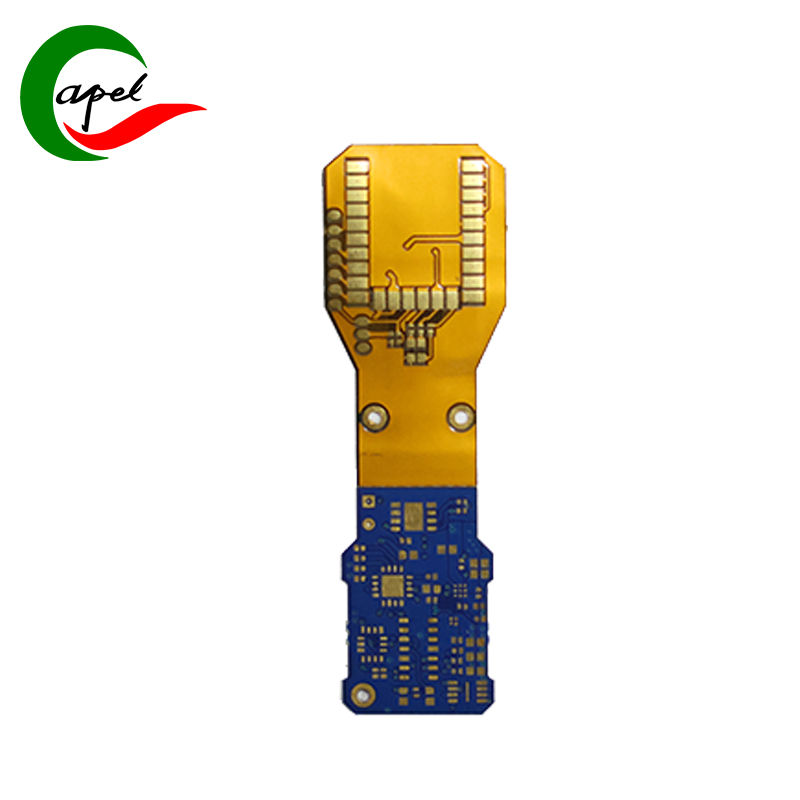

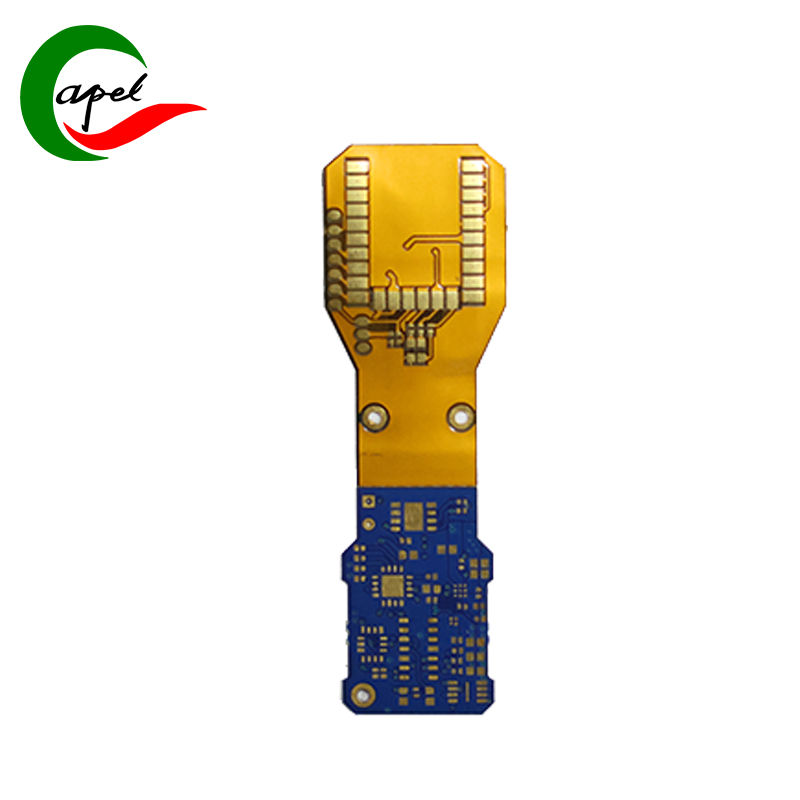

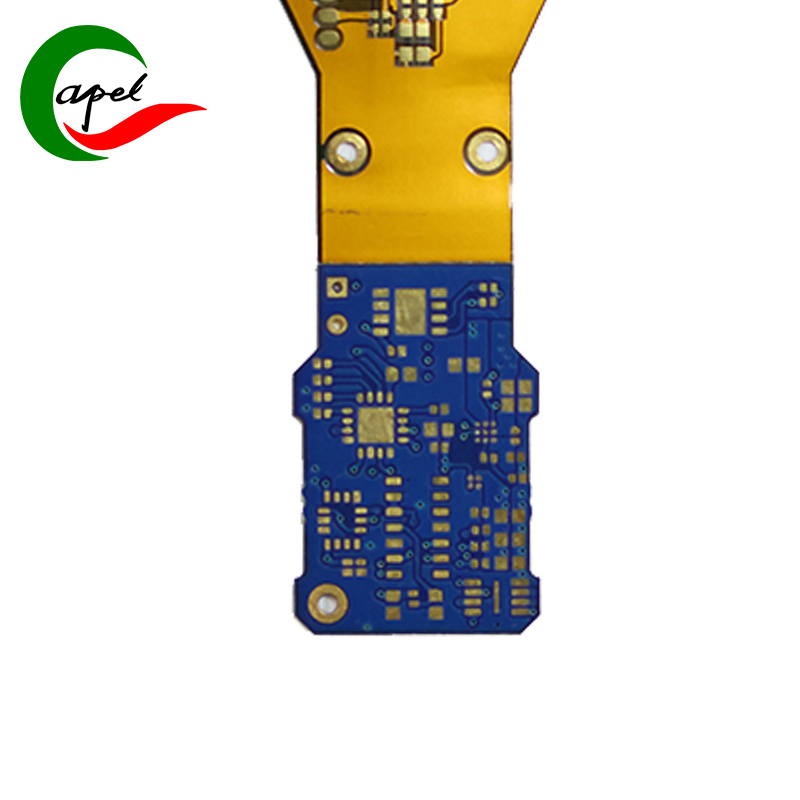

Adopting a 4-layer rigid-flex synergy structure, it perfectly balances the miniaturization needs and operational stability of communication equipment: the 0.14mm ultra-thin flexible layer offers excellent bending toughness and fatigue resistance, flexibly fitting narrow cavities, curved structures, and module connections inside communication devices. It easily avoids wiring interference and is compatible with multiple installation scenarios (portable, embedded, vehicle-mounted); the 0.6mm lightweight yet stable rigid layer meets the low-load, high-frequency operation standards of small communication equipment, reliably supporting core components such as RF chips, low-power communication modules (Wi-Fi/Bluetooth/NB-IoT), and micro connectors. This achieves efficient integration of "flexible adaptation to compact layouts + rigid fixation of precision parts". With precise dimensions of 47.5*15mm, the ultra-compact slender layout perfectly aligns with the "lightweight, miniaturized" design trend of communication equipment, saving valuable space and providing ample installation room for key components such as batteries and antennas.

Key advantages directly address the pain points of small communication equipment, demonstrating robust strength: ① Full-board immersion gold finish delivers superior low signal loss, oxidation resistance, and wear resistance, with low contact resistance ensuring high-speed, distortion-free transmission of high-frequency signals (supporting 2.4G/5G dual bands). It reduces signal attenuation and delay, meeting the requirements of long-distance stable connectivity for IoT devices and real-time response for vehicle-mounted communication; ② Solder mask with white characters + through-hole design features clear markings, facilitating automated module assembly, rapid debugging, and post-maintenance. It adapts to the mass production needs of communication equipment, significantly improving production efficiency and operational convenience; ③ 4-layer scientific wiring layout rationally separates signal, power, and ground layers, building an efficient anti-interference system. It effectively suppresses electromagnetic interference (EMI) and signal crosstalk, ensuring seamless collaboration across the full process of "signal reception - processing - transmission" even in complex environments with dense multi-device communication. It also optimizes power path design to reduce device standby power consumption.

Backed by Kaboer’s profound technical accumulation in communication-grade PCBs and strict quality control system, this 4-layer rigid-flex board can be customized based on communication equipment’s protocol requirements (e.g., 5G NSA/SA, LoRa), interface types, and power consumption standards. Paired with rapid prototyping (sample delivery within 7 days) and efficient SMT assembly services, it helps customers shorten R&D cycles and accelerate time-to-market. Whether for the low-power long standby needs of IoT devices, the lightweight design of portable terminals, or the vibration-resistant stable transmission requirements of vehicle-mounted communication modules, it serves as the "core signal hub" of communication equipment with stable performance—helping brands reduce after-sales risks and enhance product competitiveness and market reputation!