Kaboer’s 4-Layer Rigid-Flex PCB for Large Toy Cars is tailor-made for core control components of large remote-controlled toy cars, smart off-road toy vehicles, electric toy cars, and more. It precisely meets the core demands of large toy cars—shock-resistant, stable signal transmission, compact integration, and child-safe durability—combining kid-friendly safety standards with industrial-grade reliability. It’s the preferred solution for toy brands to create best-selling products, letting kids enjoy smooth control while parents have complete peace of mind!

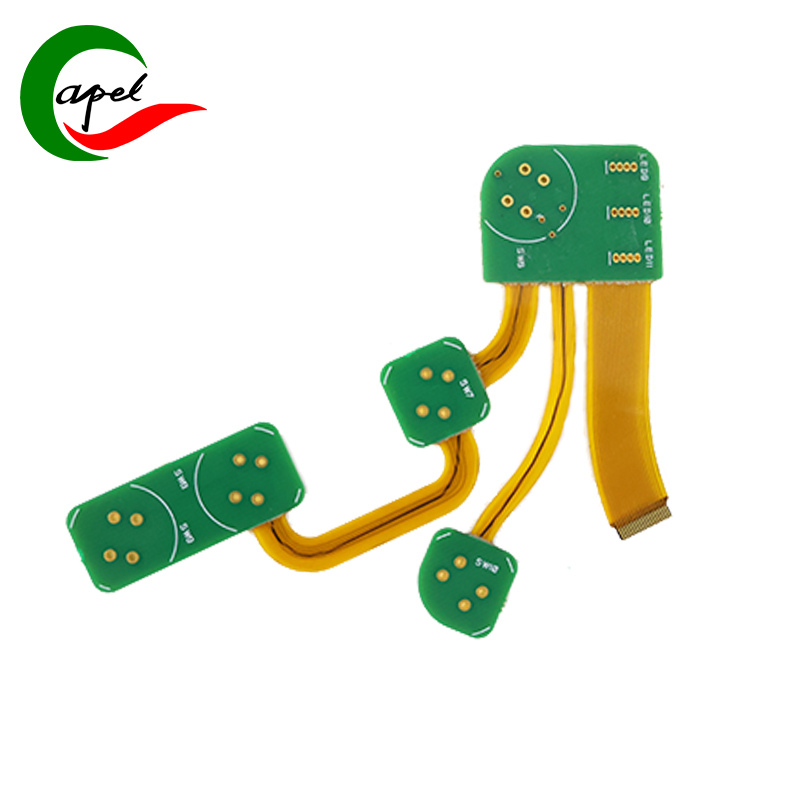

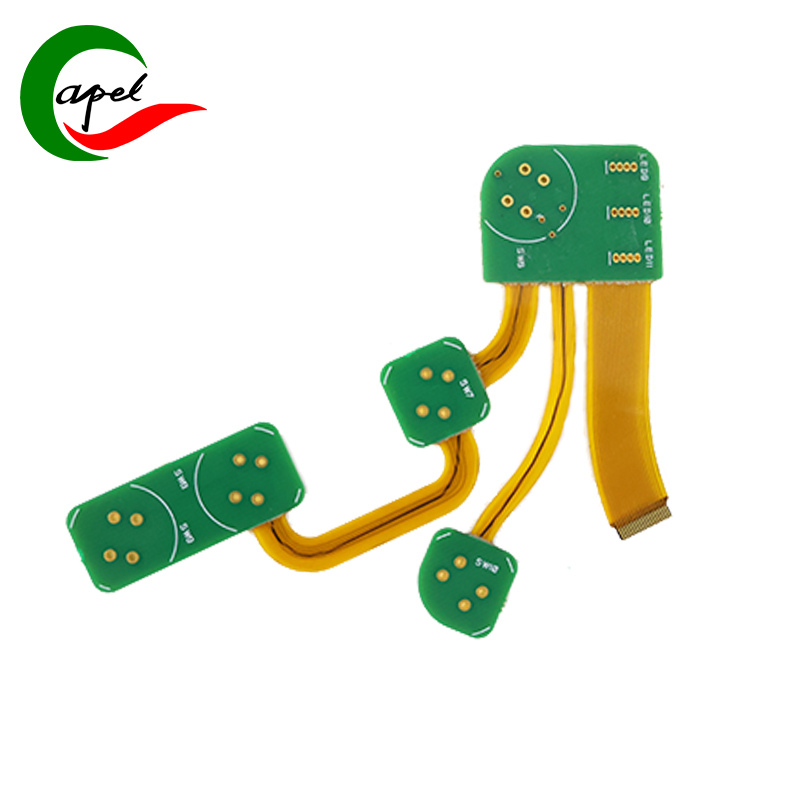

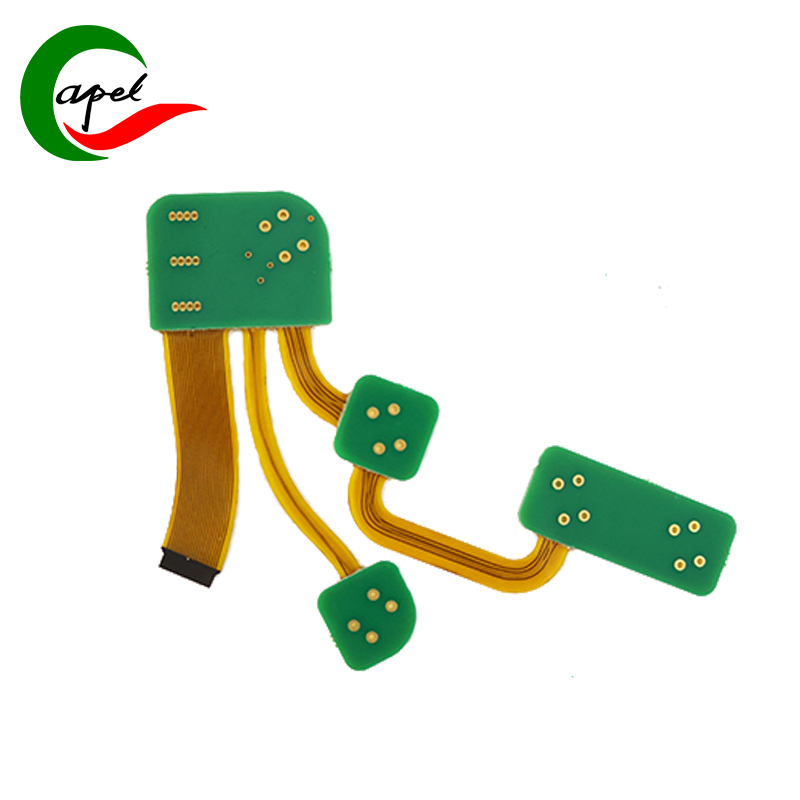

Adopting a 4-layer rigid-flex synergy structure, it perfectly balances adaptability and durability for large toy car scenarios: the 0.13mm ultra-thin flexible layer boasts exceptional bending toughness and vibration resistance, flexibly fitting complex wiring paths and connections between moving parts (e.g., wheel steering, suspension links) inside toy cars. It withstands frequent vibrations and minor impacts, completely solving the problem of traditional rigid PCBs breaking easily from drops or collisions; the 1.6mm thickened rigid layer offers superior sturdiness, meeting the high-load operation needs of large toy cars. It reliably supports core components such as motor driver chips, remote control signal receivers, obstacle avoidance sensors, and light/sound control units, enabling efficient integration of "flexible adaptation to dynamic structures + rigid fixation of precision parts". With precise dimensions of 119.46*73.46mm, the compact layout fits perfectly into the internal space of large toy cars without redundant bulk, while leaving ample room for function expansion (e.g., LED lights, Bluetooth connectivity, voice interaction).

Key advantages directly address toy car pain points, enhancing product competitiveness: ① Full-board immersion gold finish delivers excellent wear resistance, oxidation resistance, and dust-proof performance. Low contact resistance ensures high-speed, distortion-free transmission of remote control signals and motor control signals, eliminating lag or loss of control—letting kids maneuver steering, acceleration, and braking with precise, smooth responsiveness; ② White solder mask + through-hole design features clear markings, facilitating automated module assembly and post-maintenance, suitable for mass production in the toy manufacturing industry. It significantly boosts production efficiency and reduces bulk production costs; ③ 4-layer scientific wiring layout rationally separates signal, power, and ground layers, effectively suppressing electromagnetic interference (EMI) and preventing crosstalk between remote control signals and motor drive signals. Even in complex environments with multiple toy cars operating simultaneously, it ensures seamless collaboration across "signal reception - command processing - component execution", guaranteeing stable operation and far greater durability than ordinary toy PCBs.

Backed by Kaboer’s mature customization capabilities and strict quality control system, this 4-layer rigid-flex PCB can be tailored to toy car functional needs—customizing remote control protocol compatibility, sensor interfaces, light/sound module integration, and more. Paired with rapid prototyping and efficient SMT assembly services, it helps toy brands shorten R&D cycles and accelerate time-to-market. Whether for large remote-controlled off-road vehicles, smart obstacle-avoidance toy cars, or electric simulated toy cars, it serves as the "control hub" with core advantages of "child-safe durability and precise control", helping brands enhance product reputation, reduce after-sales risks, and stand out in the competitive toy market!