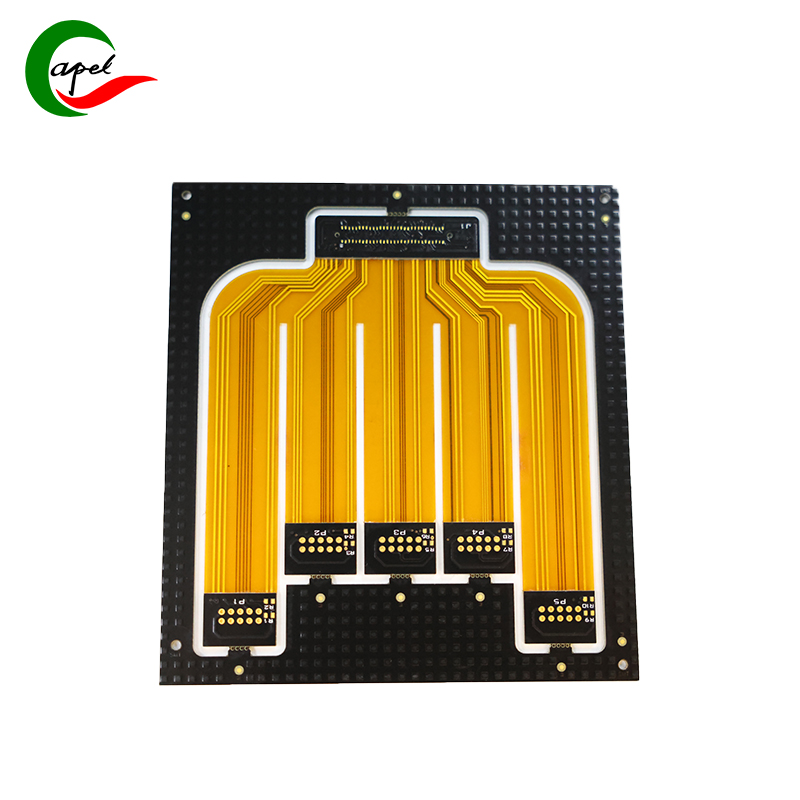

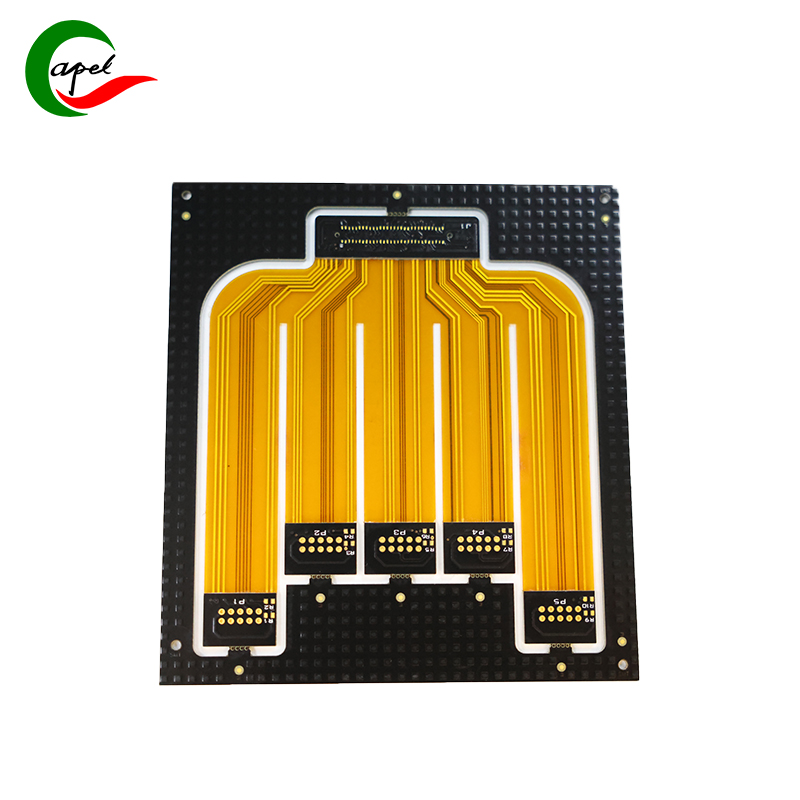

Kaboer’s 4-Layer Rigid-Flex PCB for Testing Equipment is tailored for electronic component test modules, laboratory testing devices, industrial quality inspection terminals, etc. It precisely meets the core demands of testing scenarios: accurate signaling, stable reliability, and flexible adaptation, serving as the core circuit carrier for various testing equipment.

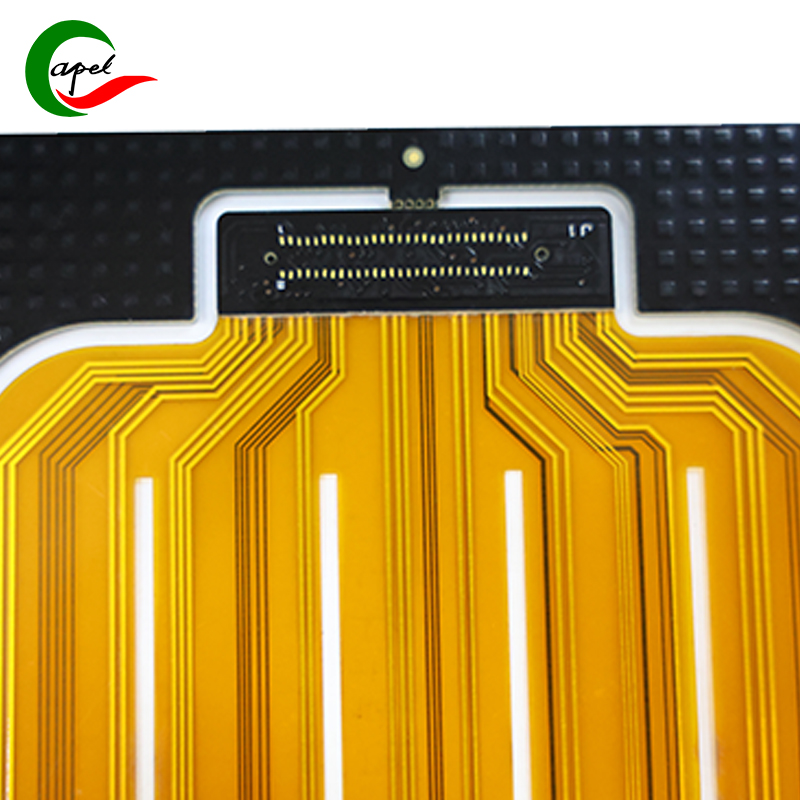

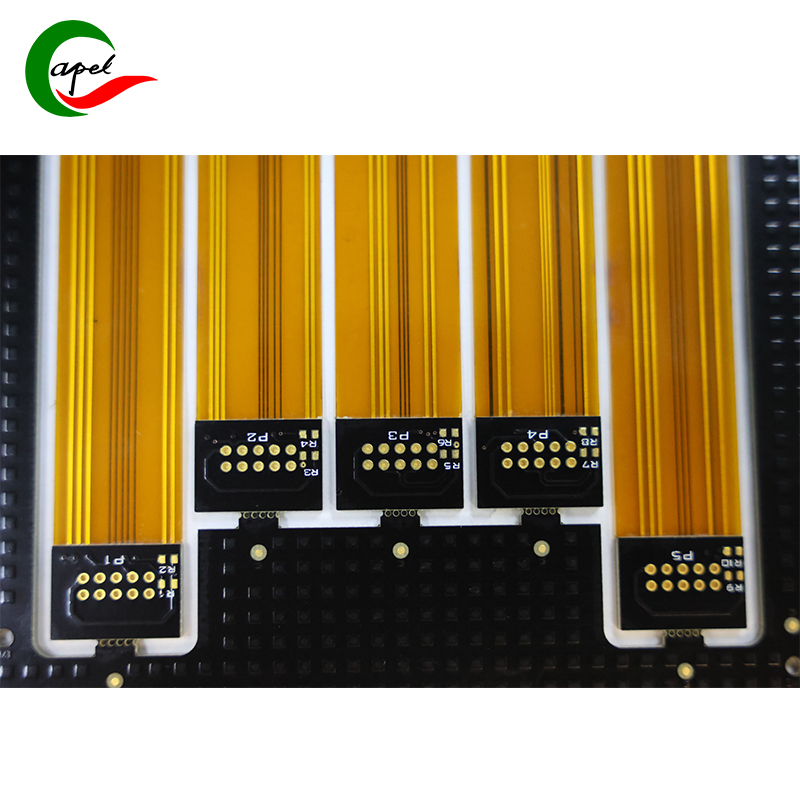

Adopting a 4-layer rigid-flex structure: the 0.186mm flexible layer offers excellent bending toughness, flexibly fitting complex wiring paths and tooling layouts inside testing equipment to avoid interference; the 1.6mm rigid layer is structurally stable, reliably supporting core components such as test chips, data acquisition modules, and connectors, enabling efficient integration of "flexible layout adaptation + rigid core fixation". With precise dimensions of 97.79*85.73mm, it fits the installation needs of various test modules without occupying redundant space.

Key advantages: ① Full-board immersion gold, featuring oxidation resistance, wear resistance from frequent plugging, and low contact resistance to ensure accurate transmission of test signals and avoid data distortion; ② White solder mask + through-hole design, clear markings for easy module assembly, debugging, and identification management, enhancing soldering reliability and post-maintenance efficiency; ③ 4-layer wiring with scientific partitioning, effectively suppressing electromagnetic interference, adapting to multi-module collaboration of testing equipment (signal collection, data processing, result output), and meeting high-precision testing requirements.

Kaboer provides customization for 1-30 layer FPC, 2-32 layer rigid-flex PCBs, paired with rapid prototyping and SMT assembly services. Covering industrial quality inspection, electronic R&D, laboratory testing and other fields, we deliver highly adaptive solutions for testing equipment development.

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

|

Category

|

Process Capability

|

Category

|

Process Capability

|

|

Production Type

|

Single layer FPC / Double layers FPC

Multi-layer FPC / Aluminum PCBs

Rigid-Flex PCB

|

Layers Number

|

1-30 layers FPC

2-32 layers Rigid-FlexPCB

1-60 layers Rigid PCB

HDI Boards

|

|

Max Manufacture Size

|

Single layer FPC 4000mm

Double layers FPC 1200mm

Multi-layers FPC 750mm

Rigid-Flex PCB 750mm

|

Insulating Layer

Thickness

|

27.5um /37.5/ 50um /65/ 75um / 100um /

125um / 150um

|

|

Board Thickness

|

FPC 0.06mm - 0.4mm

Rigid-Flex PCB 0.25 - 6.0mm

|

Tolerance of PTH

Size

|

±0.075mm

|

|

Surface Finish

|

Immersion Gold/Immersion

Silver/Gold Plating/Tin Plating/OSP

|

Stiffener

|

FR4 / PI / PET / SUS / PSA/Alu

|

|

Semicircle Orifice Size

|

Min 0.4mm

|

Min Line Space/ width

|

0.045mm/0.045mm

|

|

Thickness Tolerance

|

±0.03mm

|

Impedance

|

50Ω-120Ω

|

|

Copper Foil Thickness

|

9um/12um / 18um / 35um / 70um/100um

|

Impedance

Controlled

Tolerance

|

±10%

|

Tolerance of NPTH

Size

|

±0.05mm

|

The Min Flush Width

|

0.80mm

|

|

Min Via Hole

|

0.1mm

|

Implement

Standard

|

GB / IPC-650 / IPC-6012 / IPC-6013II /

IPC-6013III

|

Kaboer manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

2 Layer Flexible PCB Boards Stackup

4 Layer Rigid-Flex PCB Stackup

Testing And Inspection Equipment

Kaboer provide customers customized PCB Service with 15 years of experience

Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

300+Engineers Provide technical support for Pre-sales and after-sales online;

1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.