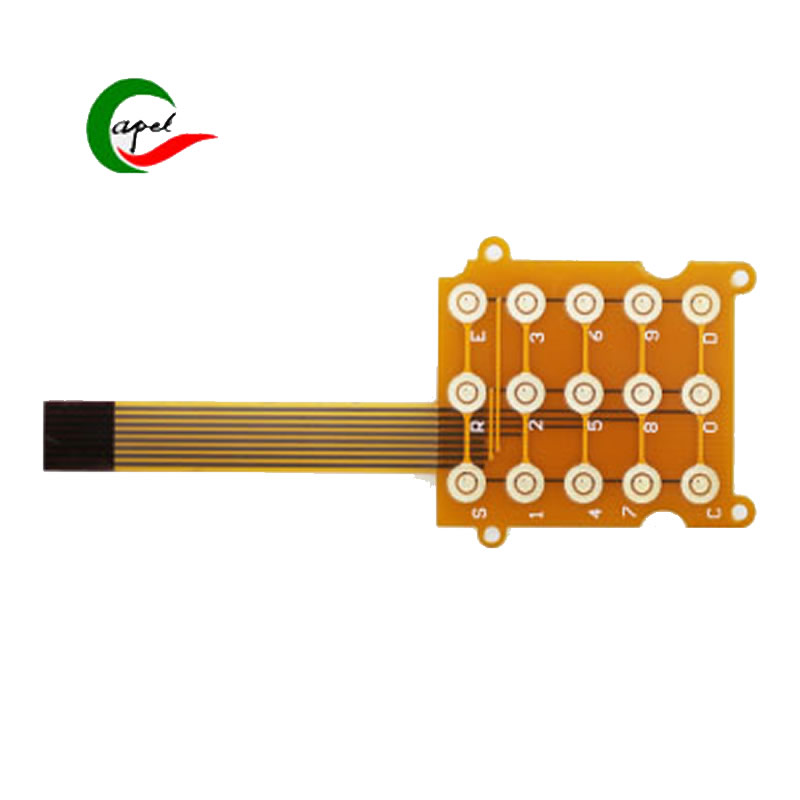

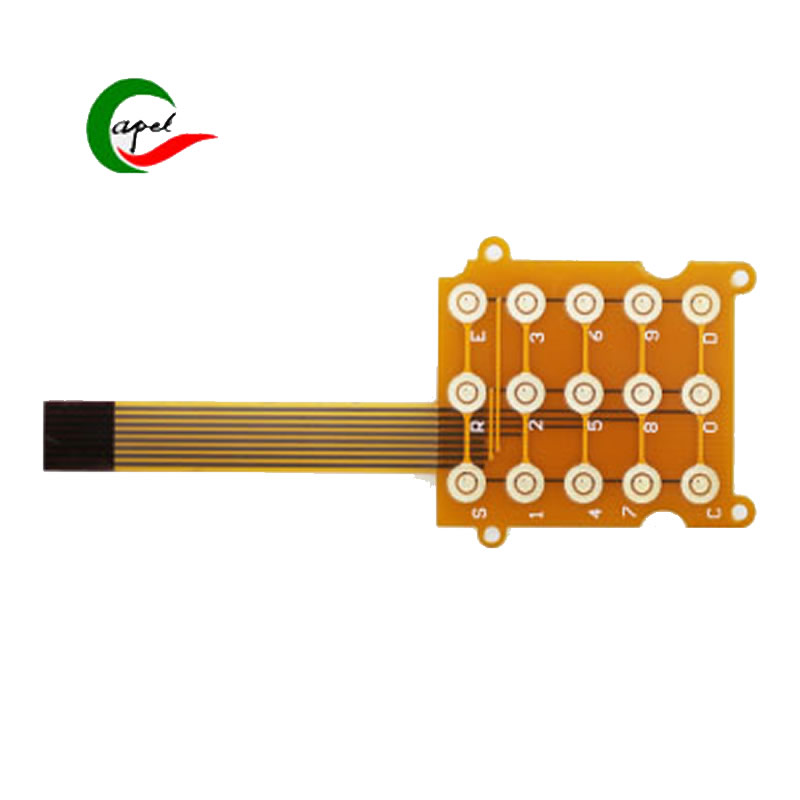

Type: Flexible board for industrial equipment display screen buttons

Minimum line width/spacing: 0.4mm/0.38mm

Layers: 1 layer

Thickness: 0.1mm

Surface treatment: Immersion gold

Kaboer's Services:

Supports customization of 1-30 layer FPC flexible PCBs, 2-32 layer rigid-flex PCBs, and 1-60 layer rigid PCBs, with reliable rapid-turnaround PCB prototype manufacturing and fast SMT PCB assembly.

Industries We Serve:

Medical equipment, Internet of Things (IoT), TWS, drones, aviation, automotive, telecommunications, consumer electronics, military, aerospace, industrial control, artificial intelligence, electric vehicles, etc.

If you have relevant needs, please click the button below to send us an email.

Type: Industrial equipment display keypad special flexible board (FPC), designed for industrial scenarios in the display and keypad circuit connection design, with excellent flexible bending performance, can be adapted to the internal industrial equipment, compact, complex spatial layout, whether it is embedded display module or external keypad panel, can be flexibly adapted to the installation, to reduce the limitations of the internal wiring of the equipment.

Layer: 1 layer structure design, in order to meet the needs of industrial equipment display and button basic circuit connection (such as signal transmission, power supply), while maximizing the simplification of the circuit structure, reduce the risk of signal interference, improve the stability of the overall circuit. The single-layer design also facilitates production and quality control, ensuring the consistency and reliability of each FPC board.

Minimum line width/spacing: 0.4mm/0.38mm, optimized for the requirements of industrial equipment for signal transmission stability. Reasonable line width and line spacing can not only ensure the efficient transmission of key command signals and display drive signals, but also adapt to the electromagnetic interference that may exist in industrial environments, reduce signal attenuation or distortion, and ensure the precise synchronization of key operation and display feedback.

Thickness: only 0.1mm, the ultimate thin and light features to support the miniaturization and integration of industrial equipment. In the scenario of limited space inside the industrial equipment, it can significantly save the installation space, avoiding the influence of the overall structural design of the equipment due to the excessive thickness of the circuit board, and at the same time reduce the weight of the equipment to enhance the convenience of installation.

Surface treatment: the use of immersion gold process, through the copper layer on the surface of the deposition of uniform nickel-gold plating, significantly enhance the corrosion resistance, wear resistance and oxidation resistance of the FPC soft board. In industrial workshops and other environments where there may be dust, oil or changes in temperature and humidity, the gold-immersion treatment can effectively protect the lines from erosion, extend the product life and reduce the frequency of equipment maintenance.

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..