Kaboer’s Single-Sided Flexible PCB for Medical Devices is tailor-made for core medical components such as benchtop diagnostic instruments, large-scale monitoring systems, peripheral modules of medical testing equipment, and rehabilitation device control units. It precisely meets the core demands of medical scenarios—regulatory compliance, stable signal transmission, sterilization resistance, and flexible adaptation. With a practical configuration of "medical-grade immersion gold finish + cost-effective single-sided wiring", it stands as a preferred solution for the R&D of medium-to-large medical equipment, empowering enterprises to build reliable, compliant, and cost-effective medical solutions!

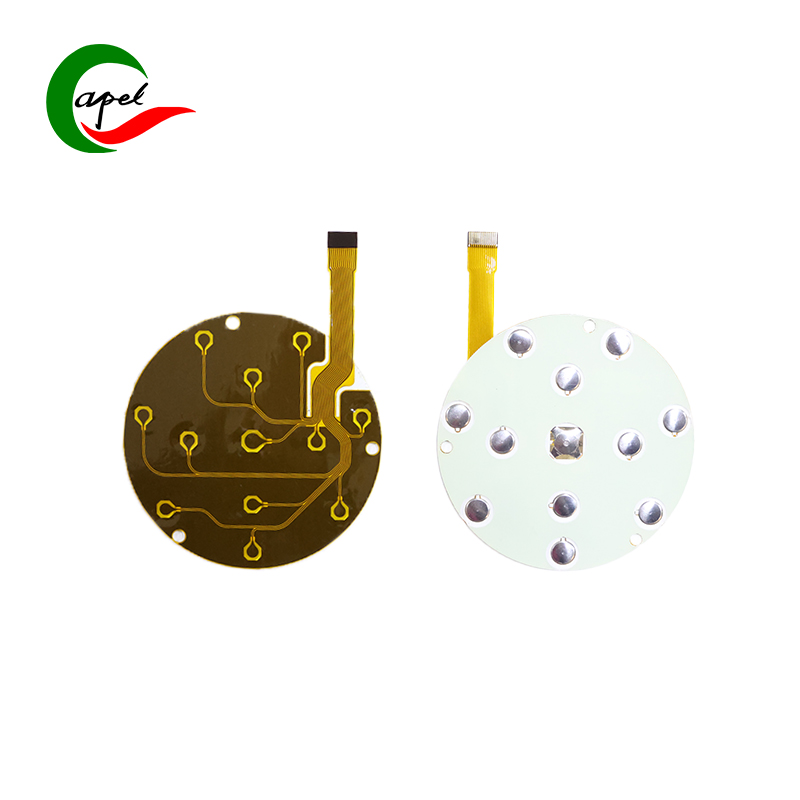

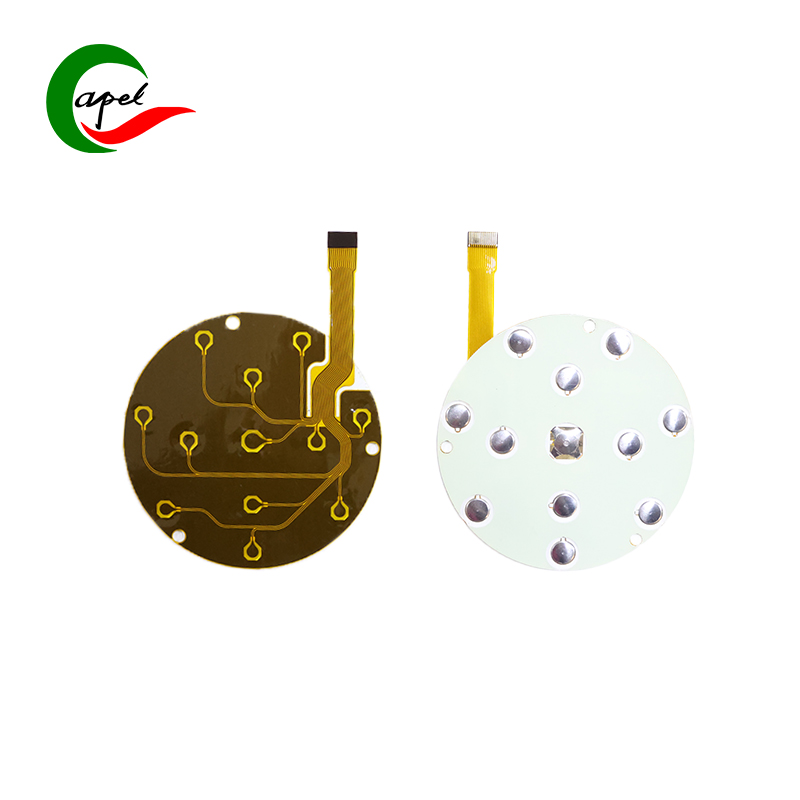

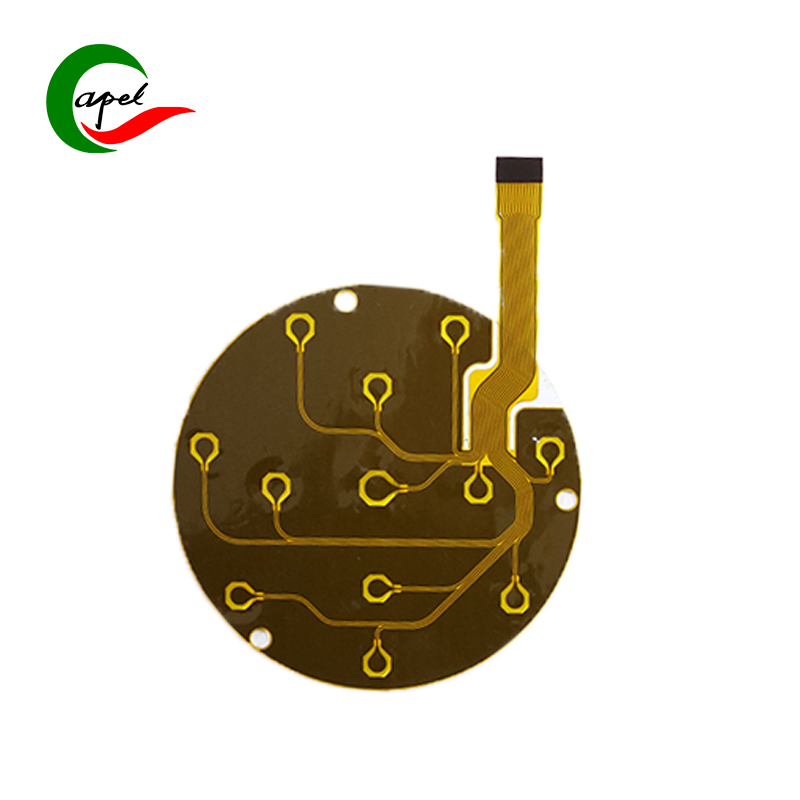

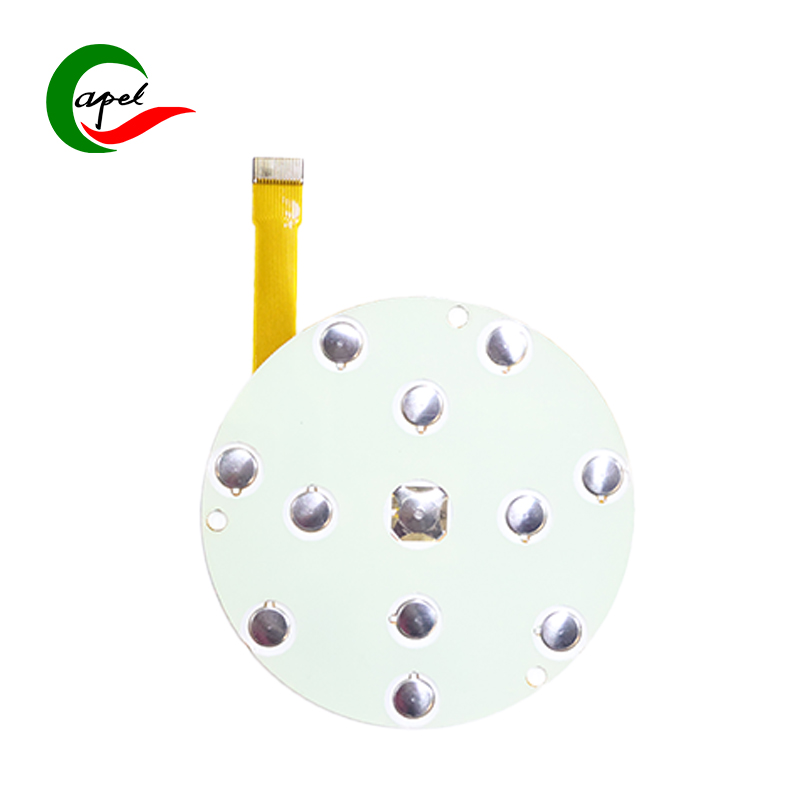

Featuring a single-sided flexible core structure, it perfectly balances the space adaptability and operational practicality of medical devices: at only 0.13mm thick, it is extremely slim with exceptional bending resilience, flexibly fitting the complex internal layouts, cavity curves, and component connection gaps of medium-to-large medical equipment. It easily avoids wiring interference, adapting to the modular design needs of devices and completely solving the pain point of traditional rigid PCBs being limited in wiring and unable to fit dynamic installation scenarios; with precise dimensions of 65*85mm, the optimized large layout meets the integration needs of multiple interfaces and components without occupying redundant space, providing ample installation room for key parts such as power modules, sensor arrays, and display units. Backed by refined manufacturing standards, the 0.15/0.1mm fine line width/spacing enables high-density integration of signal and power channels in a single-sided layout, stably carrying transmission requirements such as physiological data collection, device control commands, and power supply, and providing solid circuit support for the stable operation of medical equipment.

Key advantages directly address medical scenario pain points, demonstrating medical-grade practical performance: ① Equipped with 1mil medical-grade immersion gold finish, it offers excellent oxidation resistance, resistance to sterilization wipes (compatible with medical disinfectants like alcohol and hydrogen peroxide), and low contact resistance. It ensures high-speed, distortion-free signal transmission, eliminating detection errors caused by poor contact or oxidation. Meanwhile, the immersion gold surface enhances soldering reliability, adapting to the high-cleanliness assembly standards of medical equipment; ② The single-sided wiring design balances cost-effectiveness and practical performance, meeting the non-core signal transmission needs of medium-to-large medical equipment while effectively controlling procurement costs. It adapts to the cost optimization requirements of mass medical equipment production, with clear wiring logic that facilitates later maintenance and troubleshooting; ③ The flexible substrate complies with ISO 10993 biocompatibility standards, boasting excellent wide-temperature resistance (-40℃ to 85℃), strong fatigue resistance, and vibration resistance. It can withstand long-term continuous operation, frequent on-off cycles, and transportation jolts of medical equipment, reducing after-sales failure risks and aligning with the core demand of "low maintenance and high stability" in medical scenarios.

Backed by Kaboer’s years of medical-grade PCB R&D experience and strict quality control system, this single-sided flexible PCB is fully compatible with global medical regulatory requirements (FDA, CE, NMPA). It can be customized for circuit layout, contours, and mounting holes based on the functional needs of medical devices (e.g., interface type, signal transmission protocol, installation method). Paired with rapid prototyping and efficient SMT assembly services, it helps customers shorten R&D cycles and accelerate product certification and market launch. Whether for stable data transmission of benchtop diagnostic instruments, peripheral signal connection of large-scale monitoring systems, or control command transmission of rehabilitation devices, it serves as a "reliable signal link" for medical equipment with core advantages of "regulatory compliance, stable durability, and cost-effectiveness". It helps enterprises reduce compliance risks, control production costs, and enhance product market competitiveness and reputation!