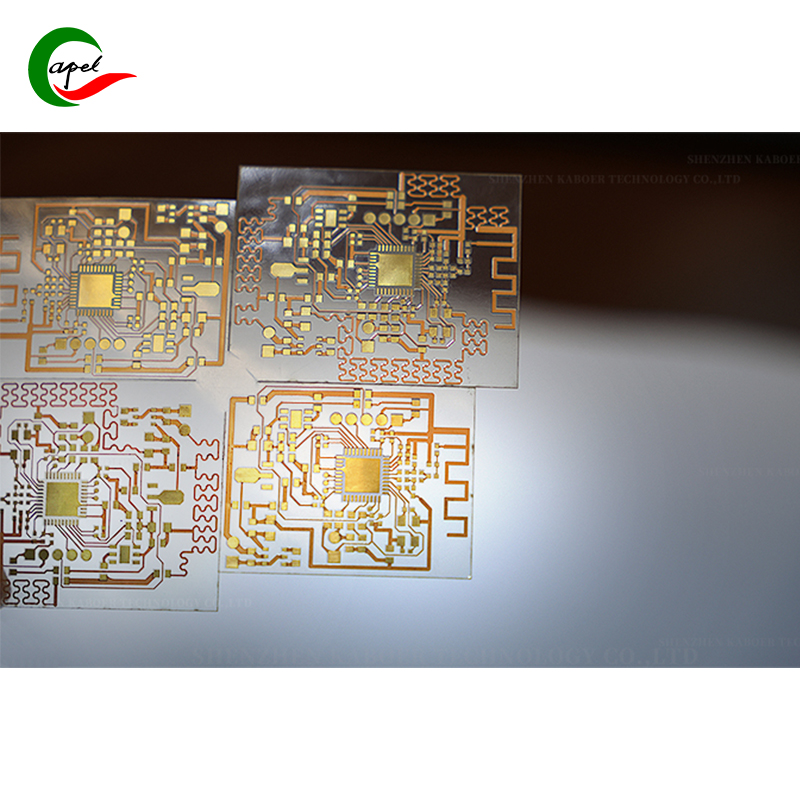

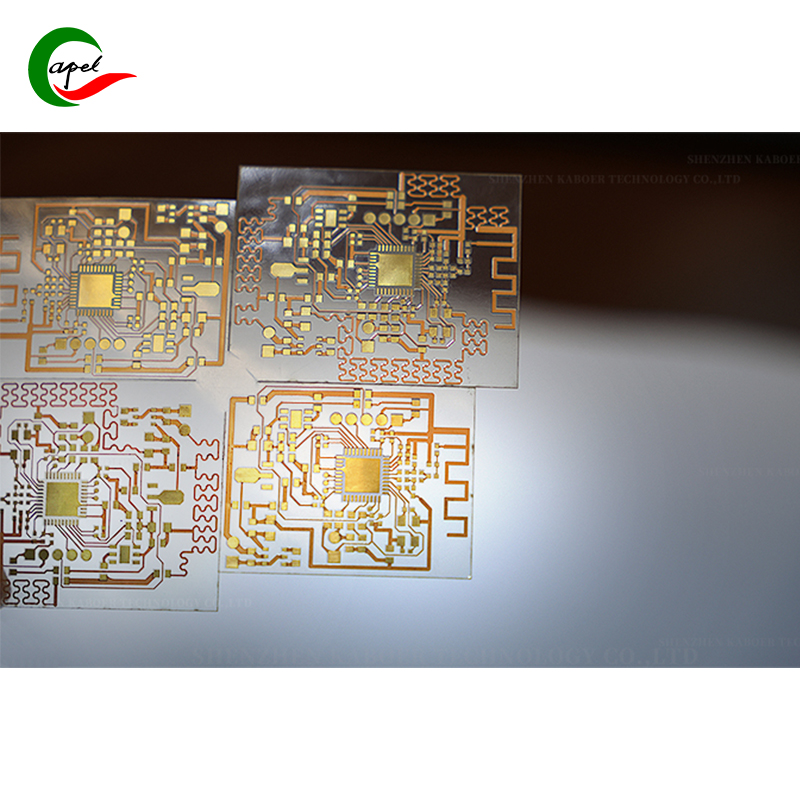

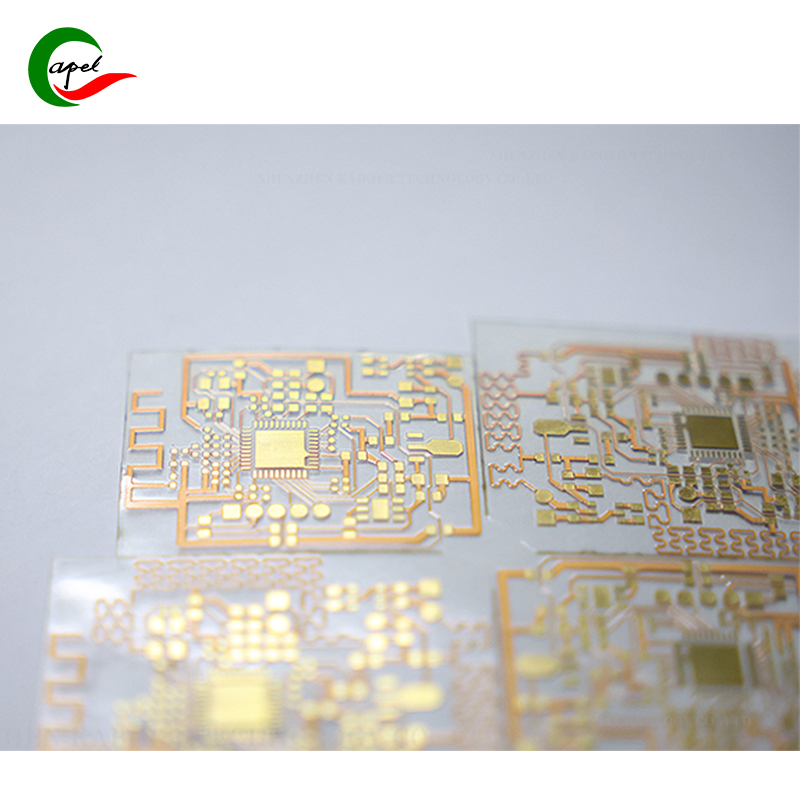

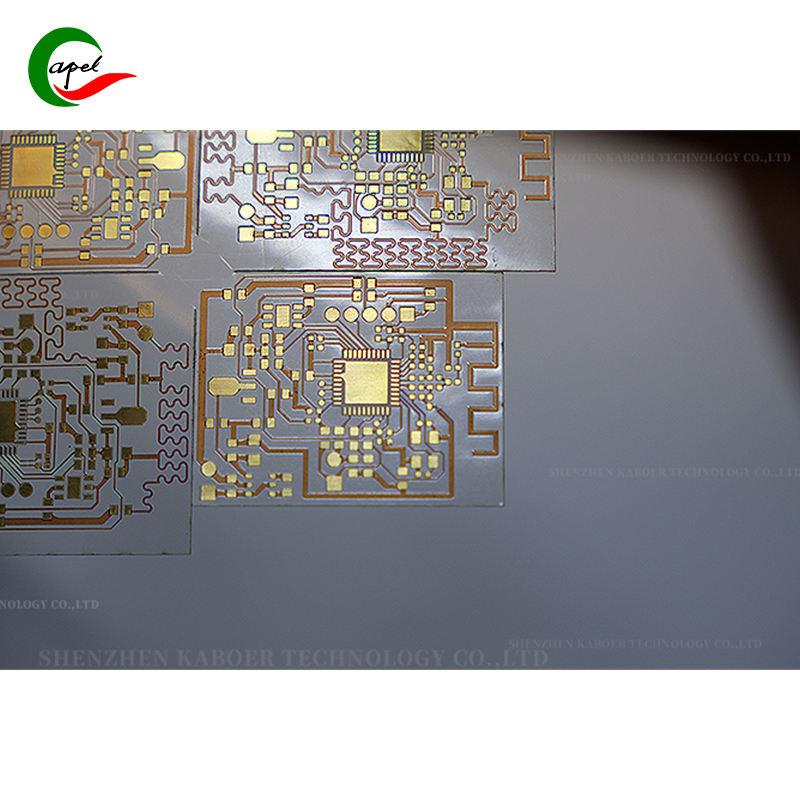

Kaboer’s Single-Sided Flexible PCB with Transparent PET Substrate is an innovative circuit component tailored for precision electronic devices requiring both light transmittance and circuit functionality. Combining three core advantages—"transparent visualization, ultra-thin flexibility, and high-density integration"—it meets the special design needs of optical-related products. Adopting a 1-layer single-sided board structure, the product’s key highlight is the use of high-light-transmission transparent PET substrate, paired with an ultra-thin 0.13mm board thickness. It not only offers excellent flexibility and bending resistance to fit curved structures, narrow installation spaces, or the inner side of light-transmitting components flexibly but also minimizes obstruction to the device’s optical functions, perfectly suitable for scenarios such as transparent display panels, smart windows, optical modules of wearable devices, and medical visualization equipment.

In terms of technical parameters and performance guarantees, the product boasts two core competitive strengths: ① Ultra-Fine Precision Wiring: Supporting high-density layout with 0.1mm trace width and 0.1mm spacing, it achieves refined circuit integration on the transparent substrate, capable of carrying complex control signals and low-power power transmission, adapting to microelectronic modules with high space utilization requirements; ② Optimized Copper Thickness: The 35μm copper thickness substrate balances good conductivity and signal transmission stability, avoiding heating or signal attenuation caused by overly thin lines, while perfectly compatible with the flexible characteristics of the PET substrate, ensuring continuous circuit conduction reliability after repeated bending. Additionally, the transparent PET substrate features environmental friendliness, non-toxicity, strong weather resistance, and high light transmittance, with no harmful substance emissions, complying with safety standards for consumer electronics and medical devices. It also has good anti-aging properties and temperature resistance (-30℃ to 80℃), adapting to multi-scenario application needs.

As a professional PCB solution provider, Kaboer offers comprehensive customization capabilities: custom manufacturing of 1-30 layer FPC flexible PCBs, 2-32 layer rigid-flex PCBs, and 1-60 layer rigid PCBs. Complemented by reliable rapid-turnaround PCB prototyping and fast SMT PCB assembly services, we help customers accelerate product R&D and mass production processes. Our services span diverse industries, including medical devices, IoT, TUT, drones, aviation, automotive, telecommunications, consumer electronics, military, aerospace, industrial control, artificial intelligence, electric vehicles, and more. With stable product quality, flexible customization solutions, and efficient delivery capabilities, we have become a trusted partner for customers across various sectors.

If you have customization needs for transparent substrate PCBs or other fields, please click the button below to send us an email. Kaboer will provide you with a tailored solution.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

|

Category

|

Process Capability

|

Category

|

Process Capability

|

|

Production Type

|

Single layer FPC / Double layers FPC

Multi-layer FPC / Aluminum PCBs

Rigid-Flex PCB

|

Layers Number

|

1-30 layers FPC

2-32 layers Rigid-FlexPCB

1-60 layers Rigid PCB

HDI Boards

|

|

Max Manufacture Size

|

Single layer FPC 4000mm

Double layers FPC 1200mm

Multi-layers FPC 750mm

Rigid-Flex PCB 750mm

|

Insulating Layer

Thickness

|

27.5um /37.5/ 50um /65/ 75um / 100um /

125um / 150um

|

|

Board Thickness

|

FPC 0.06mm - 0.4mm

Rigid-Flex PCB 0.25 - 6.0mm

|

Tolerance of PTH

Size

|

±0.075mm

|

|

Surface Finish

|

Immersion Gold/Immersion

Silver/Gold Plating/Tin Plating/OSP

|

Stiffener

|

FR4 / PI / PET / SUS / PSA/Alu

|

|

Semicircle Orifice Size

|

Min 0.4mm

|

Min Line Space/ width

|

0.045mm/0.045mm

|

|

Thickness Tolerance

|

±0.03mm

|

Impedance

|

50Ω-120Ω

|

|

Copper Foil Thickness

|

9um/12um / 18um / 35um / 70um/100um

|

Impedance

Controlled

Tolerance

|

±10%

|

Tolerance of NPTH

Size

|

±0.05mm

|

The Min Flush Width

|

0.80mm

|

|

Min Via Hole

|

0.1mm

|

Implement

Standard

|

GB / IPC-650 / IPC-6012 / IPC-6013II /

IPC-6013III

|

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

2 Layer Flexible PCB Boards Stackup

4 Layer Rigid-Flex PCB Stackup

Testing And Inspection Equipment

Capel provide customers customized PCB Service with 15 years of experience

Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

300+Engineers Provide technical support for Pre-sales and after-sales online;

1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.