Kaboer’s 6-Layer Flexible PCB for Industrial Equipment is tailor-made for core industrial devices such as industrial controllers, high-precision sensor modules, automated production line execution units, and automotive industrial-grade components. It precisely meets the core demands of industrial scenarios—high-density integration, strong anti-interference capability, ultra-thin flexible adaptation, and durability in extreme environments. With an all-round configuration of "6-layer wiring + EMI shielding + immersion gold + PI reinforcement + precise impedance control", it stands as a performance benchmark in industrial automation and smart manufacturing, empowering enterprises to build stable, efficient, and risk-resistant industrial-grade solutions!

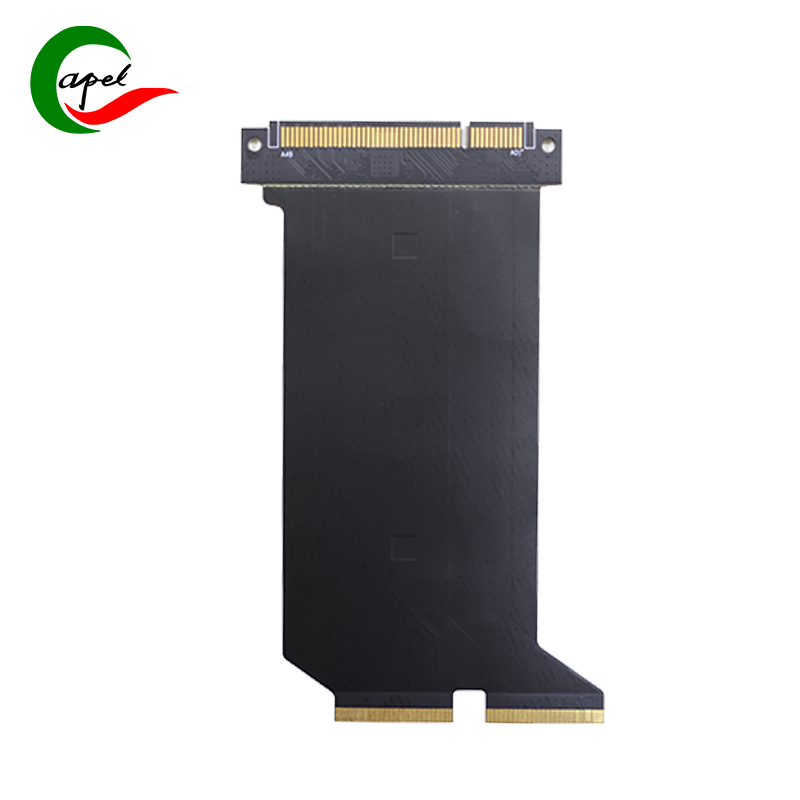

Featuring a 6-layer flexible core with localized PI reinforcement, it perfectly balances the space adaptability and operational reliability of industrial equipment: at only 0.12mm thick, it is extremely slim with exceptional bending resilience, flexibly fitting narrow cavities, complex wiring paths, and connections between dynamic components (e.g., robotic arm joints, module interfaces) inside industrial devices. It easily avoids wiring interference, adapting to the compact and modular design needs of industrial equipment, and completely solving the pain points of traditional multi-layer PCBs (wiring restrictions and inability to fit dynamic scenarios); PI reinforcement in critical areas enhances mechanical strength of interfaces, solder joints, and high-density wiring zones while ensuring flexible adaptation, improving deformation resistance and plug-in durability. It can withstand high-frequency vibrations and frequent assembly operations in industrial environments, extending product service life. Backed by refined manufacturing standards, the 0.12/0.09mm ultra-fine line width/spacing and 0.1mm micro drill size enable ultra-high-density integration of signal and power channels, accommodating transmission of multiple groups of industrial-grade signals (e.g., control commands, sensor data) in limited space and providing sufficient circuit support for multi-functional integration and high-precision operation of equipment.

Key advantages directly address industrial pain points, demonstrating industrial-grade robustness: ① Quadruple protection of 2μm immersion gold finish, EMI shielding, PI reinforcement, and impedance control—the immersion gold surface offers superior oxidation resistance, corrosion resistance, and wear resistance, with low contact resistance ensuring high-speed, stable transmission of industrial signals; the EMI shielding layer effectively blocks external electromagnetic interference, avoiding signal crosstalk among multiple devices in industrial environments and guaranteeing data transmission integrity; the PI reinforcement layer is high-temperature resistant and anti-aging, enhancing structural stability; precise impedance control (within ±10%) adapts to industrial high-frequency signal transmission needs, eliminating signal distortion; ② The 6-layer scientific wiring layout rationally separates signal, power, and ground layers, enabling separate transmission of signals and power to further strengthen anti-interference capability. It also significantly improves space utilization and transmission efficiency, supporting integration of multiple sensor interfaces and driver unit channels, and adapting to the composite needs of "multi-module collaboration and high-precision control" for industrial equipment; ③ The flexible substrate performs excellently in extreme environments, withstanding a wide temperature range (-40℃ to 125℃), humidity, dust, and other harsh industrial conditions. It boasts strong fatigue resistance, capable of withstanding tens of thousands of bending cycles, adapting to long-term continuous operation and dynamic working scenarios of industrial equipment (e.g., connections of mechanical moving parts), and reducing downtime and maintenance risks.

Backed by Kaboer’s profound technical accumulation in industrial-grade PCBs and strict quality control system, this 6-layer flexible PCB can be customized for impedance parameters, reinforced area layout, wiring density, shielding levels, and other requirements based on industrial equipment application scenarios (automated production/automotive industrial/IoT industrial terminals). Paired with rapid prototyping and efficient SMT assembly services, it helps customers shorten R&D cycles and accelerate mass production. Whether for precise command transmission of industrial controllers, data collection of high-precision sensors, or continuous stable operation of automated production lines, it serves as the "core control hub" of industrial equipment with core advantages of "high density, strong anti-interference, extreme durability, and flexible adaptation". It empowers enterprises to improve production efficiency, reduce after-sales risks, and build competitive advantages in the smart manufacturing track!