Kaboer’s 3-Layer Flexible PCB for Test Fixtures is engineered for core components in precision-driven test environments—including electronic inspection jigs, PCB test fixtures, semiconductor probe modules, and high-frequency signal test tools. It precisely addresses the core demands of test fixtures: high-precision signal transmission, resistance to frequent mating cycles, flexible adaptation to complex geometries, and zero-error detection. With a robust configuration of "ultra-fine wiring + reinforced structure + precise impedance control", it stands as a performance benchmark for electronic manufacturing and semiconductor testing, empowering businesses to boost test efficiency, minimize detection errors, and deliver highly reliable testing solutions!

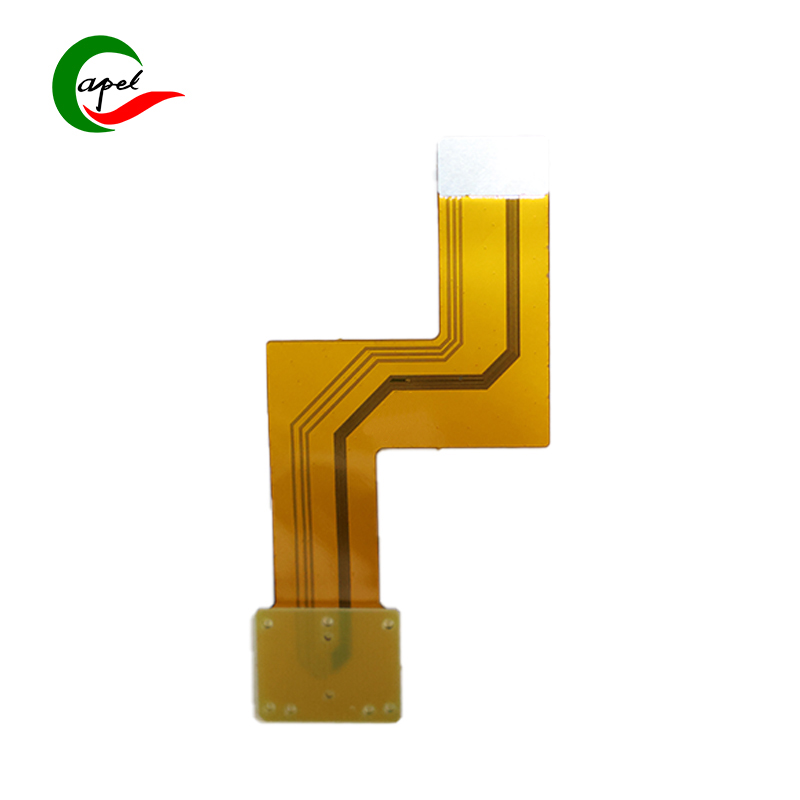

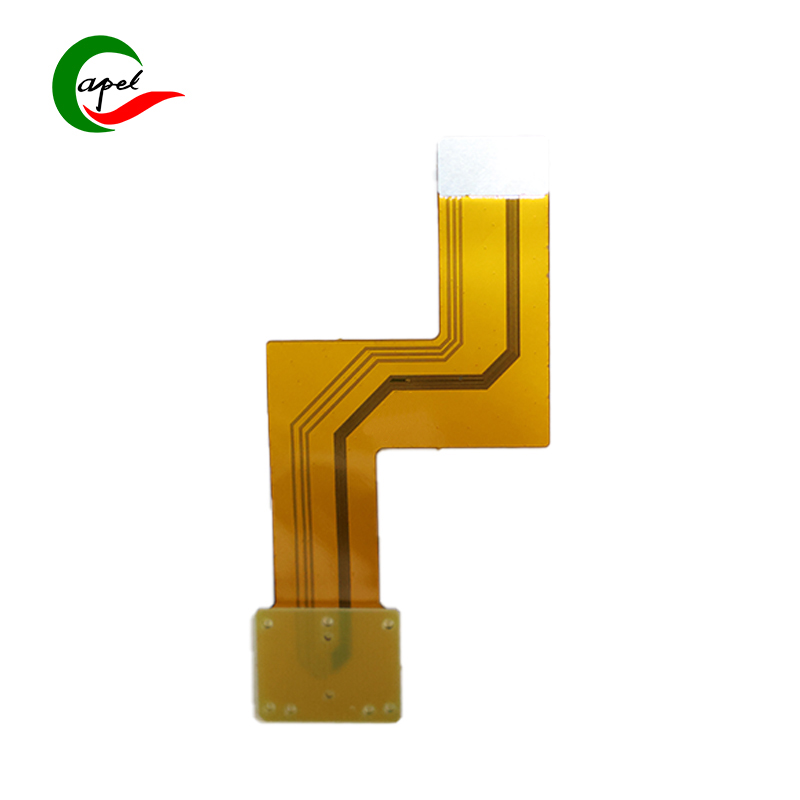

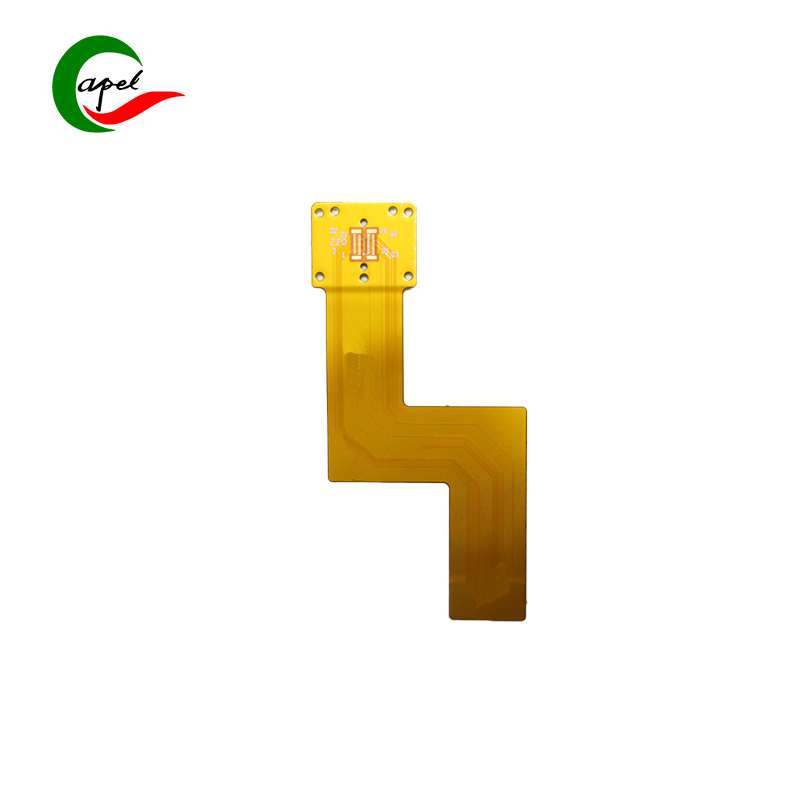

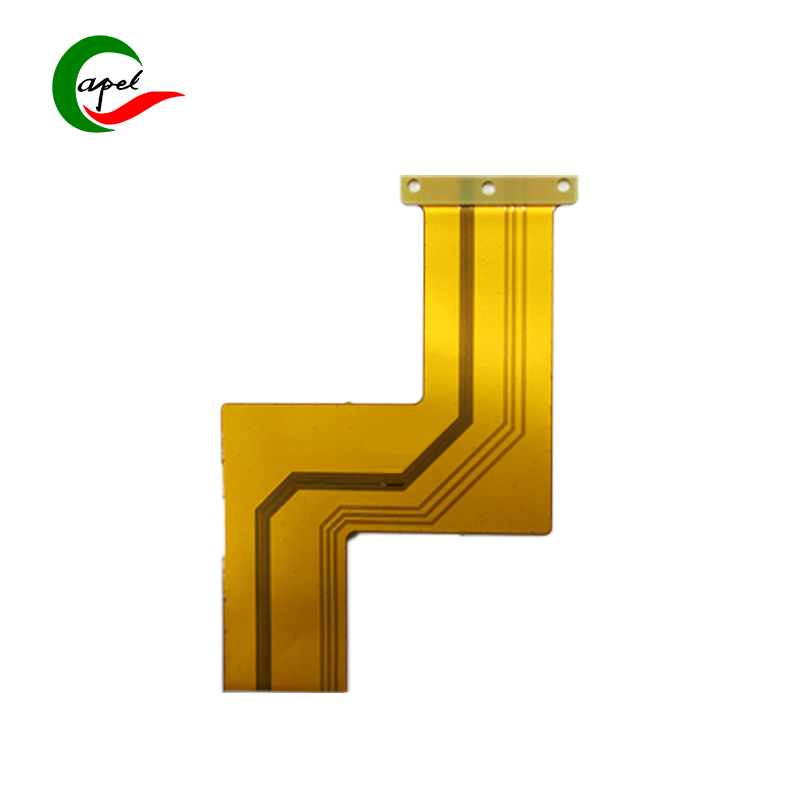

Featuring a 3-layer flexible core structure, it strikes the perfect balance between test fixture precision and durability: at just 0.2mm thick, the flexible substrate offers exceptional bending resilience, seamlessly conforming to complex curved surfaces, narrow cavities, and probe array layouts in test fixtures. It eliminates wiring interference, adapting to the compact, high-density design requirements of miniaturized test tools; combined with FR4 local reinforcement and a steel foil layer, it enhances mechanical strength without compromising flexibility—boasting superior wear and deformation resistance to withstand tens of thousands of probe insertions and test cycles. This solves the critical pain points of traditional flexible PCBs: premature wear and structural deformation. Built to rigorous manufacturing standards, its 0.05/0.076mm ultra-fine line width/spacing and 0.2mm micro-via design enable ultra-high-density wiring and precise probe interface integration, accommodating more test channels in limited space and supporting multi-pin, high-precision component inspection.

Key advantages directly tackle test fixture challenges, delivering precision test-grade performance: ① The triple-enhanced design—1μm immersion gold finish, steel foil layer, and FR4 reinforcement—ensures rugged reliability. The immersion gold surface provides excellent wear and oxidation resistance, the steel foil layer enhances signal shielding and structural stability, and FR4-reinforced zones boost pressure resistance at probe connections—all working in tandem to guarantee consistent performance under high-frequency mating. Precise impedance control (within ±10%) enables distortion-free transmission of GHz-level high-frequency test signals, reducing signal reflection and attenuation for accurate data collection and eliminating misjudgments caused by signal errors; ② The 3-layer wiring architecture and ultra-fine lines maximize signal density and transmission efficiency, supporting integration of multiple probe interfaces and sensor channels. It adapts to multi-dimensional testing of complex components while minimizing PCB footprint, enabling miniaturization and lightweight design of test fixtures; ③ The flexible substrate performs reliably across a wide temperature range (-40℃ to 85℃), with excellent aging and fatigue resistance. It thrives in industrial continuous-testing environments, extending test fixture lifespan and lowering replacement and maintenance costs.

Backed by Kaboer’s deep technical expertise in precision PCBs and strict quality control systems, this 3-layer flexible PCB can be customized for impedance parameters, reinforced area layouts, line density, and more—tailored to specific test fixture applications (semiconductor testing/consumer electronics inspection/automotive electronics validation). Paired with rapid prototyping (sample delivery within 7 days) and efficient SMT assembly services, it helps customers shorten fixture R&D cycles and accelerate time-to-market. Whether for high-precision semiconductor chip testing, high-density PCB inspection, or high-frequency signal tool validation, it serves as the "signal backbone" of test fixtures, delivering precise transmission and rugged durability. It empowers businesses to enhance detection accuracy and efficiency, reduce after-sales risks, and gain a competitive edge in electronic manufacturing quality control!