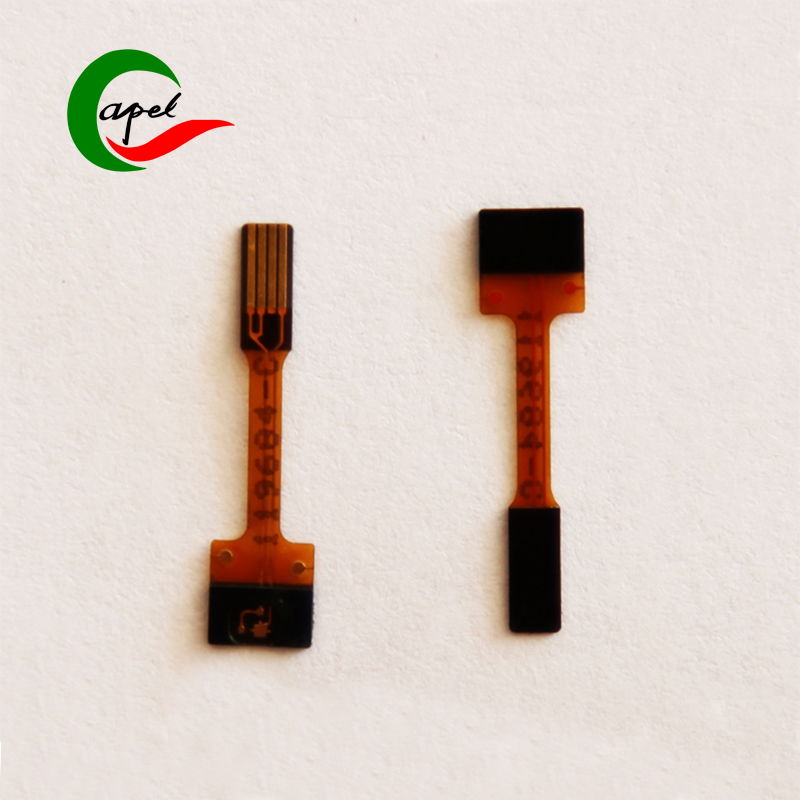

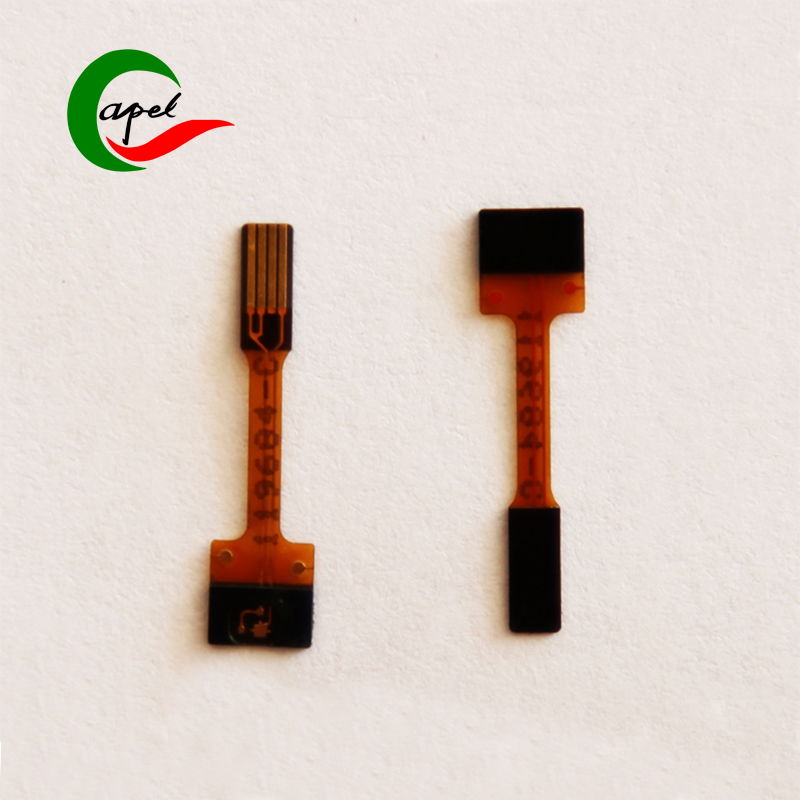

Automotive Sensor FPC

A short introduction:

Type: Automotive Sensor FPC

Minimum Line Width/Line Spacing: 0.15mm/0.13mm

Number of Layers: 1 Layer

Thickness: 0.13mm

Surface Finish: Electro-Rigid Gold 30 micro inches

Capel's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layer Rigid-Flexible Circuit Boards, 1-60 Layer Rigid PCB, Reliable Fast Turnaround PCB prototyping, rapid SMT PCB assembly

Industries we serve:

Medical devices, IoT, TUT, drones, aerospace, automotive, telecom, consumer electronics, military, aerospace, industrial control, AI, electric vehicles, etc. ......

If you have related needs, please feel free to send us an email by clicking the button below.

Type: Flexible Printed Circuit (FPC) for automotive sensors, specially designed for in-vehicle sensor systems, with excellent flexible adaptation and environmental resistance. Whether it is the chassis of the tire pressure sensor, the engine compartment temperature sensor, or the body of the collision sensor, automatic driving millimeter wave radar sensor, can be flexibly adapted to the sensor installation of the complex scene (such as narrow space, vibration environment, high and low temperature areas), to achieve the weak sensing signals (such as mV voltage signal, μA current signal) accurate conduction, to provide the ECU real-time, reliable vehicle condition data support. 2. Fine Parameters and Performance Guarantee

Minimum line width/spacing: 0.15mm/0.13mm high precision standard. This parameter is optimized for the characteristics of the sensor's weak signal: 0.15mm line width ensures that the sensing signals (such as the tire pressure sensor's pressure signal) have lower transmission loss (signal attenuation rate of ≤0.3dB/m), reducing the distortion of weak signals in transmission; 0.13mm line spacing in the limited space of the wiring to achieve independent cabling, support for the sensor power supply line, signal line, ground line transmission to avoid interference with the signal (such as power supply fluctuations), to avoid the interference with the signal (such as the power supply fluctuation of the power supply to the signal line). Power supply fluctuations on the signal interference (such as common mode noise rejection ratio ≥ 60dB), to ensure signal purity.

Layers: 1-layer structure design to achieve efficient signal transmission through minimalist structure:

Single layer adopts “signal + ground” parallel wiring to shorten the length of the signal path and reduce signal delay (transmission delay ≤ 100ns);

Simplified structure reduces production complexity and improves product consistency, especially suitable for mass-produced standardized sensors Simplified structure reduces production complexity and improves product consistency, which is especially suitable for mass-produced standardized sensors (e.g., general-purpose tire pressure sensor for passenger cars).

The single-layer design guarantees performance while significantly reducing cost, which is suitable for automotive sensors in large-scale applications.

Thickness: Only 0.13mm thin and light, perfect for the miniaturization of sensors and installation space constraints. In the car sensor “miniaturization” trend (such as diameter <20mm embedded sensors), can significantly reduce the wiring on the sensor installation space occupation, adapt to the chassis, engine compartment and other narrow areas of the wiring path; at the same time to enhance the flexibility of bending (support for the smallest bending radius R = 1mm), to adapt to the sensors along with the vibration of the body dynamic scenarios, to avoid the fatigue of wiring At the same time, it improves the flexibility of bending (supporting the minimum bending radius R=1mm, adapting to the dynamic scenario of sensor vibration with the body, and avoiding fatigue breakage of wiring.

Surface treatment: the use of electro-hard gold 30 micro-inch process (gold layer thickness ≥ 0.76μm), bringing multiple automotive-grade advantages:

hard gold layer hardness (Vickers hardness ≥ 180HV), excellent abrasion resistance, can withstand the sensor plug-connection or long-term vibration friction (insertion and removal of the life of ≥ 1,000 times without wear and tear);

gold layer of conductivity and stability, the contact resistance of ≤ 5mΩ, reducing the transmission of weak sensing signals, to ensure signal acquisition accuracy (error). To ensure the accuracy of signal acquisition (error rate ≤ 0.5%);

30 micro-inch thickened gold layer is highly corrosion-resistant, through 5000 hours of salt spray test without rust, adapt to the engine compartment oil, chassis mud and water and other harsh environments, to prolong the service life of the sensor (design life of ≥ 15 years / 200,000 kilometers).

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB | Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm | Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..