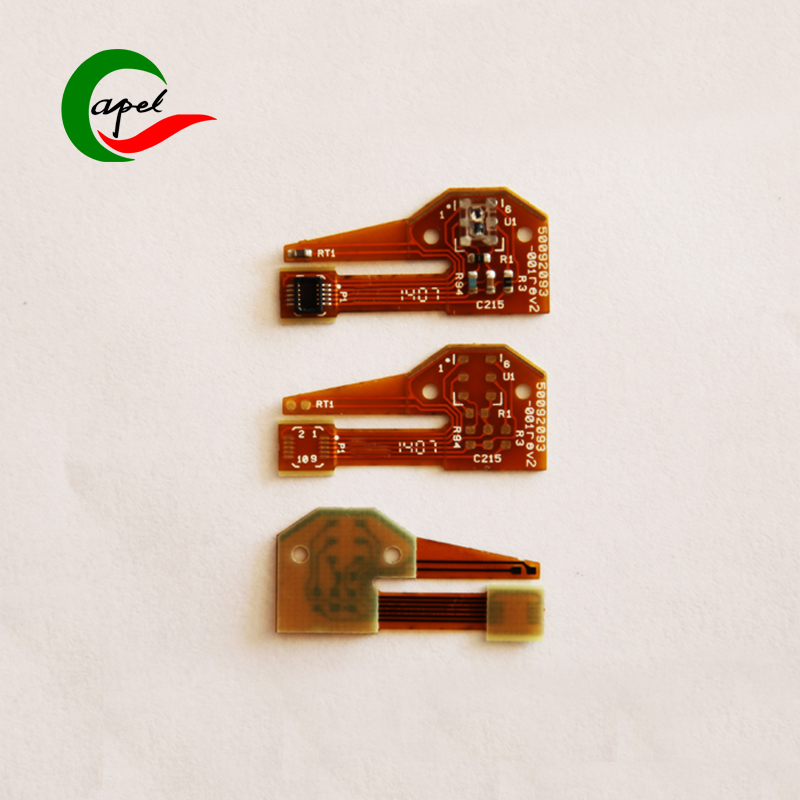

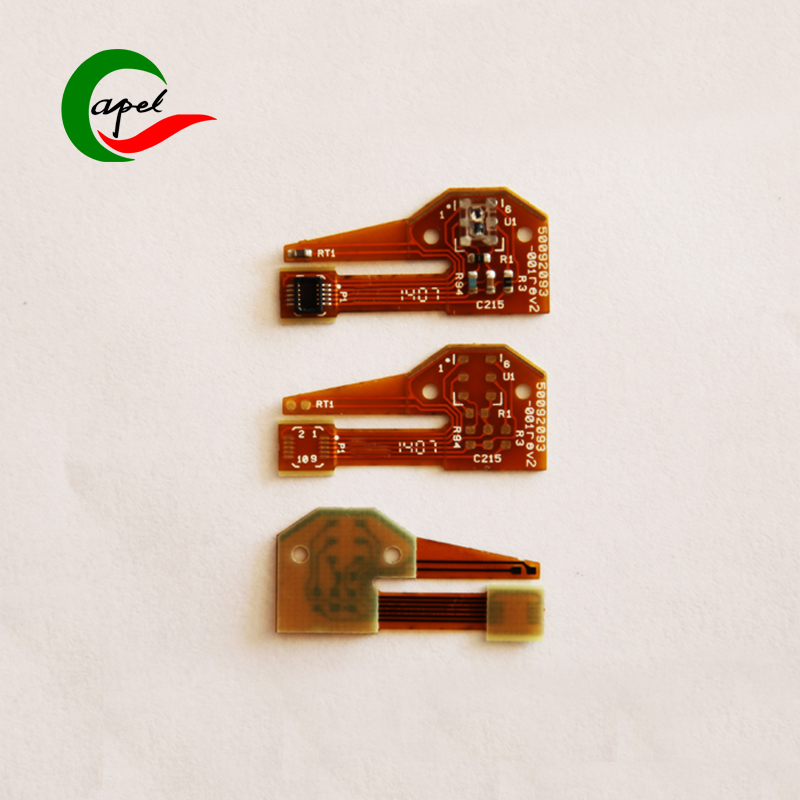

Industrial Temperature Controller FPC

A short introduction:

Type: Industrial Temperature Controller FPC

Minimum Line Width/Line Spacing: 0.2mm/0.17mm

Number of Layers: 1 Layer

Thickness: 0.13mm

Surface Finish: Immersion Gold

Kaboer's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layer Rigid-Flexible PCB, 1-60 Layer Rigid PCB, Reliable Fast Turnaround PCB Prototyping, Rapid SMT PCB Assembly

Industries We Serve:

Medical Device, IoT, TUT, UAV, Aviation, Automotive, Telecom, Consumer Electronics, Military, Aerospace, Industrial Controls, Artificial Intelligence, Electric Vehicles, etc. ......

If you have related needs, please feel free to click the button below to send us an email.

Type: Industrial temperature controller special flexible circuit board (FPC), designed for industrial temperature control scenarios, adapted to PT100/PT1000 platinum resistance, thermocouples and other sensors signal transmission, as well as heating wire, refrigeration film and other actuating elements of the control command transmission. Whether it is a high temperature temperature control module for ovens and reactors (working temperature ≤150℃), a precision temperature control system for constant temperature incubators (accuracy ±0.05℃), or vibration-resistant temperature control equipment for industrial furnaces and kilns, it can be flexibly adapted to the compact internal layout of the controller (e.g., the narrow gap between the sensors and the motherboard, and the curved mounting position of the equipment panel), replacing the traditional cables or rigid PCBs, and improving equipment resistance to vibration and vibration at the same time as reducing signal loss. Instead of traditional cables or rigid PCBs, it reduces signal loss and improves vibration and temperature resistance of the equipment.

Minimum line width/spacing: 0.2mm/0.17mm industrial grade precision standard. This parameter is optimized for temperature control signal characteristics: 0.2mm line width to ensure that the PT100 sensor's weak resistance signal (temperature change of 1 ℃ corresponds to a resistance change of 0.385 Ω) lower transmission loss (signal attenuation rate of ≤ 0.05%/m), to ensure the accuracy of the temperature measurement (error ≤ ± 0.1 ℃); at the same time, support for the heating element of the small-current control (the maximum load-bearing current of 2A) to avoid overheating of the line; 0.17mm line width / spacing: to reach 0.2mm/0.17mm industrial grade accuracy standards. Line overheating; 0.17mm line spacing in the limited space to achieve “sensor signals + control commands + power supply” three lines of independent wiring to reduce power supply noise on the weak temperature signal interference (interference error ≤ ± 0.05 ℃), to ensure consistency of the measurement of low-temperature section (-50 ℃) and high-temperature section (200 ℃).

Layers: 1 layer structure design, through the streamlining of the layout to achieve “signal transmission efficiency maximization”:

single layer using “signal - power - ground” parallel wiring, shorten the sensor signal transmission path (delay ≤ 10ms), reduce the temperature feedback hysteresis. Suitable for rapid heating / cooling down scenarios (such as injection mold temperature control, temperature rise and fall rate ≥ 5 ℃ / min);

large-area grounding copper foil and signal lines adjacent to the design, the formation of a “signal - ground” shielding structure, inhibit the industrial environment of motors, frequency converters of electromagnetic interference (EMI suppression ≥ 45dB), especially suitable for multi-equipment centralized plant scenarios. It is especially suitable for the scenarios of factory buildings where multiple equipments are concentrated.

The single-layer design reduces circuit complexity and improves vibration resistance (reducing the risk of interlayer stripping) while ensuring signal purity.

Thickness: 0.13mm thin and light, perfect for industrial equipment “compact space + flexible installation” needs. In the embedded temperature control module (such as equipment panel), can significantly reduce the occupation of installation space (thickness of only 1/3 of the traditional rigid PCB); in the need for slight bending of the parts (such as the sensor probe and the controller's connection), can adapt to the minimum bending radius R = 5mm of the curvature, to avoid vibration caused by the equipment line breakage, and at the same time to maintain the stability of the signal (after bending the resistance change rate of ≤ 1%). Surface treatment: the use of immersion gold technology (the resistance change rate after bending ≤ 1%)

Surface treatment: the use of immersed gold technology (nickel layer thickness ≥ 5μm, gold layer thickness ≥ 0.05μm), bringing multiple industrial-grade advantages:

excellent conductivity of the gold layer, contact resistance ≤ 30mΩ, to reduce the sensor signal transmission loss, to ensure that the low-temperature environment (-40 ° C) is still able to capture the stability of weak signals (such as thermocouples mV voltage);

immersed gold plating layer of corrosion resistance, can be subject to the oil, dust and erosion of the industrial workshop (through 72%). The immersed gold plating is highly corrosion-resistant and can withstand oil and dust erosion in industrial workshops (no corrosion after 72 hours of neutral salt spray test), and can adapt to humid (95% relative humidity) and dusty environments;

enhances the reliability of the solder joints to ensure that the soldered parts of the wires, sensor interfaces and relays do not loosen during long-term vibration (10-2000Hz, acceleration of 5g), thus prolonging the service life of the equipment (design life ≥ 5 years).

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..