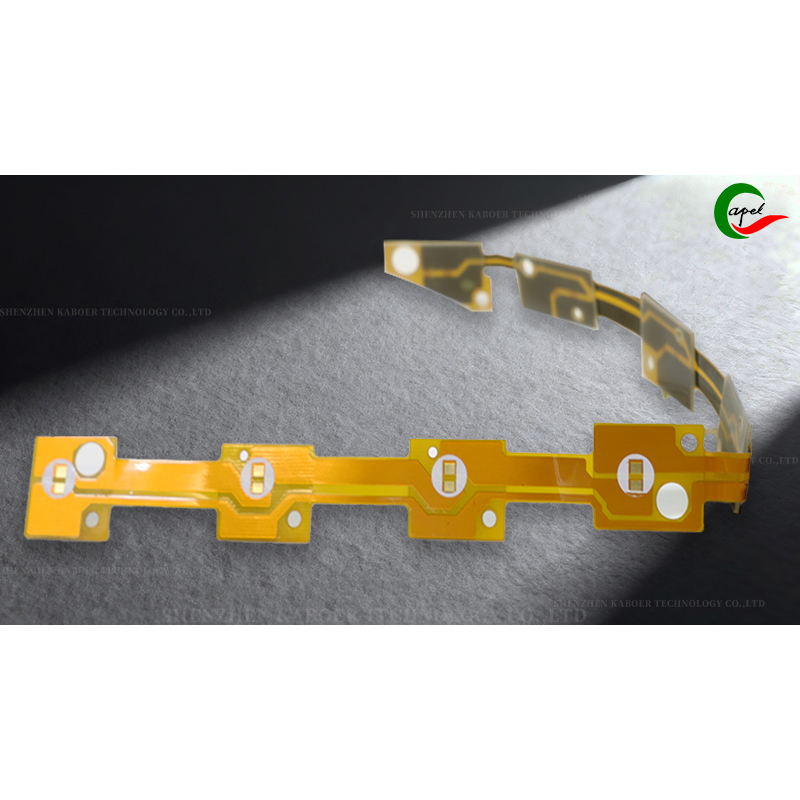

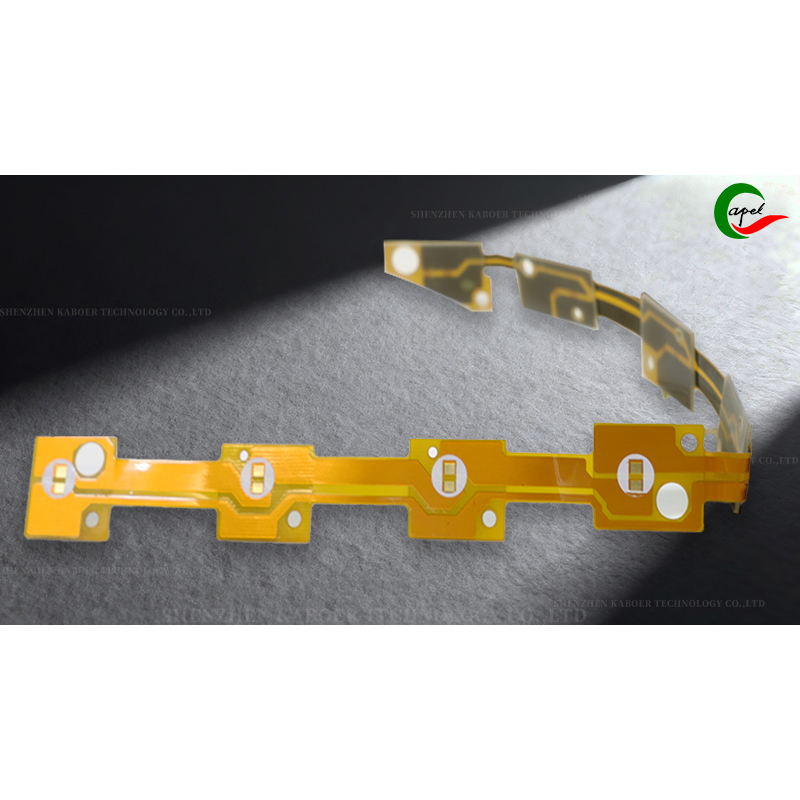

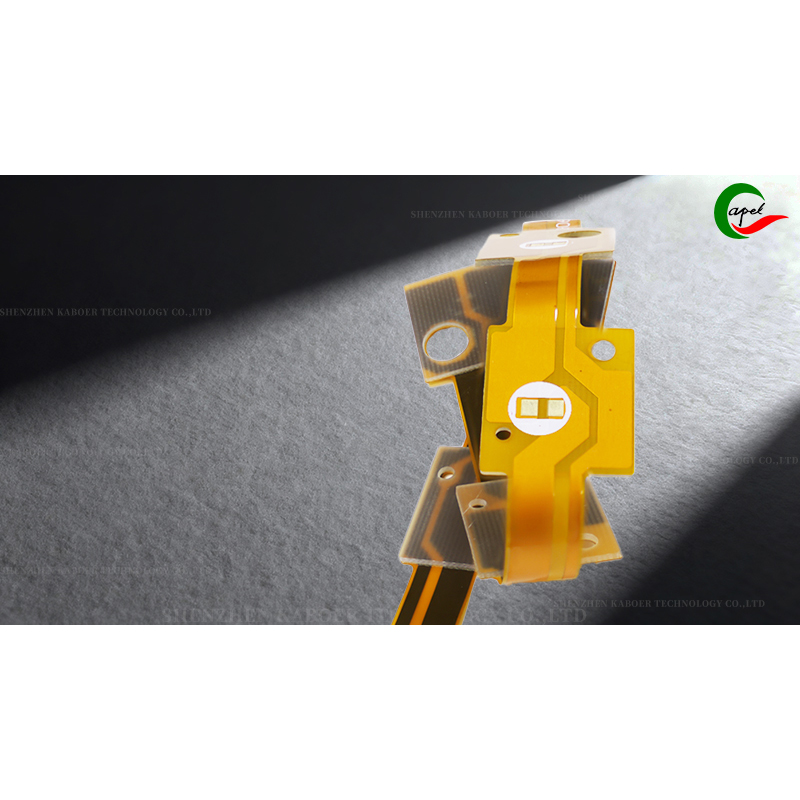

Kaboer’s Single-Sided Flexible PCB for Automotive Applications is a high-adaptability circuit component tailored for low-to-medium power in-vehicle electronic systems (such as power window controls, seat adjustment modules, automotive lighting auxiliary units, and door control switches). It features a streamlined structure and automotive-grade reliability to meet the core demands of automotive electronics—stability, durability, and compactness. Adopting a 1-layer single-sided board design with a precisely controlled thickness of 0.13mm, it combines extreme thinness with excellent flexibility, enabling seamless fit into narrow installation spaces and complex curved surfaces inside vehicles (e.g., door panels, seats, central consoles). It occupies no redundant in-vehicle space while withstanding high-frequency vibrations, jolts, and other mechanical stresses during vehicle operation, preventing circuit breakage or loose connections, and aligning with the lightweight and integrated design trends of automotive electronics.

In terms of technical parameters and performance guarantees, the product adopts a reasonable layout with 2mm trace width and 1mm spacing. The wide 2mm trace width ensures stable transmission of low-to-medium power current and control signals, adapting to the signal conduction needs of non-complex in-vehicle circuits; the sufficient 1mm spacing guarantees insulation reliability between lines, effectively avoiding short-circuit risks caused by temperature changes and dust accumulation in the in-vehicle environment. Equipped with 1 microinch (approximately 0.0254μm) immersion gold surface finish, the uniform and dense gold layer offers excellent oxidation resistance and wear resistance, resisting erosion from high temperatures, oil contamination, and humidity changes in the automotive environment, reducing contact resistance, and ensuring long-term stable circuit conduction with minimal equipment failure probability. The product uses automotive-grade temperature-resistant substrates, operating within a wide temperature range of -40℃ to 125℃, and also boasts good oil resistance and anti-aging properties, fully complying with the strict reliability standards of automotive electronics.

As a professional PCB solution provider, Kaboer offers comprehensive customization capabilities for automotive PCBs: custom manufacturing of 1-30 layer FPC flexible PCBs, 2-32 layer rigid-flex PCBs, and 1-60 layer rigid PCBs. Complemented by reliable rapid-turnaround PCB prototyping and fast SMT PCB assembly services, we help automotive electronics clients accelerate product R&D and mass production processes. Our services span diverse industries, including Medical Devices, IoT, TUT, Drones, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, Electric Vehicles, etc. With rigorous quality control, flexible customization solutions, and efficient delivery capabilities, we have become a trusted partner in the automotive electronics sector.

If you have customization needs for automotive application PCBs or other field-related PCBs, please click the button below to send us an email. Kaboer will provide you with a tailored solution.

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

|

Category

|

Process Capability

|

Category

|

Process Capability

|

|

Production Type

|

Single layer FPC / Double layers FPC

Multi-layer FPC / Aluminum PCBs

Rigid-Flex PCB

|

Layers Number

|

1-30 layers FPC

2-32 layers Rigid-FlexPCB

1-60 layers Rigid PCB

HDI Boards

|

|

Max Manufacture Size

|

Single layer FPC 4000mm

Double layers FPC 1200mm

Multi-layers FPC 750mm

Rigid-Flex PCB 750mm

|

Insulating Layer

Thickness

|

27.5um /37.5/ 50um /65/ 75um / 100um /

125um / 150um

|

|

Board Thickness

|

FPC 0.06mm - 0.4mm

Rigid-Flex PCB 0.25 - 6.0mm

|

Tolerance of PTH

Size

|

±0.075mm

|

|

Surface Finish

|

Immersion Gold/Immersion

Silver/Gold Plating/Tin Plating/OSP

|

Stiffener

|

FR4 / PI / PET / SUS / PSA/Alu

|

|

Semicircle Orifice Size

|

Min 0.4mm

|

Min Line Space/ width

|

0.045mm/0.045mm

|

|

Thickness Tolerance

|

±0.03mm

|

Impedance

|

50Ω-120Ω

|

|

Copper Foil Thickness

|

9um/12um / 18um / 35um / 70um/100um

|

Impedance

Controlled

Tolerance

|

±10%

|

Tolerance of NPTH

Size

|

±0.05mm

|

The Min Flush Width

|

0.80mm

|

|

Min Via Hole

|

0.1mm

|

Implement

Standard

|

GB / IPC-650 / IPC-6012 / IPC-6013II /

IPC-6013III

|

Kaboer manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

2 Layer Flexible PCB Boards Stackup

4 Layer Rigid-Flex PCB Stackup

Testing And Inspection Equipment

Kaboer provide customers customized PCB Service with 15 years of experience

Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

300+Engineers Provide technical support for Pre-sales and after-sales online;

1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.