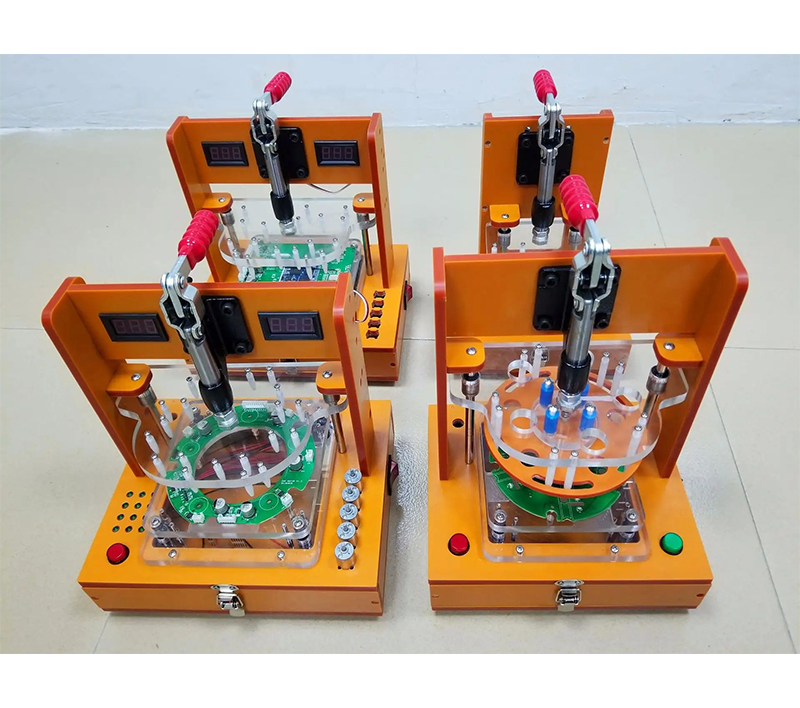

High quality 2 Layer Flex pcb for Medical Device Test Fixture-Case

| Technical requirements | ||||||

| Product type | Double Sided Flex Circuit Pcb Board | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing | 0.12/0.1mm | |||||

| Board thickness | 0.15mm | |||||

| Copper Thickness | 18um | |||||

| Minimum Aperture | 0.15mm | |||||

| Flame Retardant | 94V0 | |||||

| Surface Treatment | Immersion Gold | |||||

| Solder Mask Color | Yellow | |||||

| Stiffness | PI、FR4 | |||||

| Application | Medical Device | |||||

| Application Device | Infrared Analyzer | |||||

Case Study

Capel’s 2-layer PFC flex circuit is a versatile and reliable product serving a wide range of industries, with specific applications in test fixtures industrial control. This case analysis highlights the technical innovation points of each product parameter and proposes solutions to technical problems to further improve the industry and equipment.

Line width and line spacing:

Capel's flexible circuits have line widths and line spacing of 0.13 mm and 0.18 mm respectively. This parameter reflects Capel's technical expertise in achieving high precision and fine detail in circuit design. Narrower line widths and spacing allow complex circuits to be built in limited space, resulting in higher circuit density and improved performance.

Technology solution:

To further enhance line width and spacing capabilities, Capel can invest in advanced manufacturing technology and equipment to achieve finer line width and spacing. This improvement will meet the industry's growing demand for miniaturization and support the development of more advanced, compact electronic devices.

Plate thickness:

Capel's flexible circuit boards are 0.2 mm thick. This parameter marks Capel’s technological innovation in realizing ultra-thin flexible circuit boards. The board's slim profile allows easy integration into space-constrained applications.

Technical solutions:

To address potential technical issues related to board thickness, Capel can explore advanced materials and technologies that provide greater flexibility without compromising durability. In addition, working with material suppliers to develop thinner yet stronger materials can further optimize the performance of Capel's flexible circuits.

Copper thickness:

The copper thickness of Capel's flexible circuit is 35um, which has excellent conductivity and sufficient current carrying capacity. This technological innovation guarantees reliable signal transmission and power distribution in industrial control applications and test fixtures.

Technology Solution:

To meet the industry's changing higher power requirements, Capel could consider offering variations in copper thickness, such as thicker copper options for applications requiring increased current capacity. This customization will allow Capel's flexible circuits to adapt to a wider range of industry and equipment requirements.

Minimum aperture:

Capel's flexible circuits feature a minimum hole diameter of 0.2 mm, demonstrating the precision drilling capabilities of the manufacturing process. This technological innovation enables precise interconnection and component placement in circuit design. Technology solution:

To meet the needs of future industry trends, Capel can invest in advanced laser drilling technology. Laser drilling offers greater precision and the ability to create smaller apertures while maintaining high quality. This advancement will support the development of more complex circuit designs and meet the need for miniaturization.

Non-flammable:

Capel's flexible circuits have a 94V0 flame retardant rating. This technological innovation ensures that products comply with the strict safety standards of various industries. Flame retardant properties prevent circuit boards from starting fires and mitigate risks associated with electrical equipment.

Technology solution:

To further improve flame retardant performance, Capel can work with material suppliers to explore advanced flame retardant materials that provide enhanced protection without compromising other properties such as flexibility and durability. This improvement will meet the industry's growing demand for highly reliable and secure electronic components. Surface treatment:

The immersion gold finish of Capel flex circuits increases the circuit's conductivity and corrosion resistance. This technological innovation ensures long-term reliability and high-quality signal transmission.

Technology Solutions:

Capel can continuously optimize and expand the range of surface treatment options to meet specific industry requirements. For example, the introduction of surface treatments with specific properties, such as enhanced solderability or improved resistance to harsh environments, will provide Capel with opportunities to further address the unique needs of different industries and equipment.

Resistance welding color: Capel's flex circuits feature a yellow resistance welding color that serves as a visual indicator during the manufacturing and assembly process. This technological innovation simplifies production workflows and minimizes the risk of errors in component placement and soldering.

Technical Solution:

Capel may consider offering custom options in resistance welding colors to meet customer specific preferences or requirements. This flexibility will increase customer satisfaction and further streamline production processes.

Post time: Sep-09-2023

Back