A 15-Meter-Long Flexible PCBs Applicated in Aerospace

Capel warmly welcome Dr. Li Yongkai and Dr. Wang Ruoqin from Hong Kong University of Science and Technology and their team to visit our company for guidance and technical exchange, and jointly witness the success of our cooperation project, and the successful completion of the 15-meter special ultra-long Flexible Printed Circuit Boards.

After receiving the project requirements of the ultra-long Flexible PCBs from Dr. Li and Dr. Wang, Capel company organized a technical team. Through detailed technical communication with Dr. Li and Dr. Wang, we understood the detailed needs of the customers. Through internal technical discussion and analysis, the technical team formulated a detailed production plan. Special extra long Flex PCBs of 15 meters were successfully produced.

Successfully witnessed the application of a 15-meter long flexible Printed Circuit Boards in the innovative transformable ultrasonic transducer Aerospace. that can be bent approximately 4000 times with a testing bend radius of 0.5 mm. The folding process of this flexiblecircuit board can be precisely controlled to achieve various forms, which are critical for the transforming process of Aerospace.

The success of this Flexible PCBs marks another breakthrough in our technology, and the production capacity of the company has been greatly improved, which has accumulated valuable experience for the production of the company.

CAPEL Dedicated to Automotive

CAPEL's Printed circuit boards (PCBs) for vehicles offer several advantages. They save space, enhance reliability, improve performance and facilitate service and maintenance. Capel's PCBs are cost-effective to produce, provide design flexibility, and are durable in harsh vehicle conditions. They also support efficient power management, helping to reduce weight and enable scalability. In summary, Our PCBs offer advantages such as space saving, reliability, performance, cost-effectiveness, design flexibility, durability, power management, weight reduction, and scalability in automotive electronics.

CAPEL Dedicated to Medical Devices

Capel's Printed circuit boards (PCBs) are essential components in medical device development. They enable the integration of electronic components, resulting in smaller and more portable devices. Capel's PCBs improve the reliability and accuracy of medical devices by providing a stable platform for signal transmission. They can be customized to meet specific requirements, allowing the development of specialized equipment. Capel's PCBs facilitate communication between different components and systems, enabling wireless connectivity. Their cost-effectiveness helps make medical equipment more affordable. Capel's PCBs also ensure compliance with industry standards and safety regulations to ensure patient safety. Overall, Capel's PCBs play a key role in the advancement of medical devices, improving patient care and well-being.

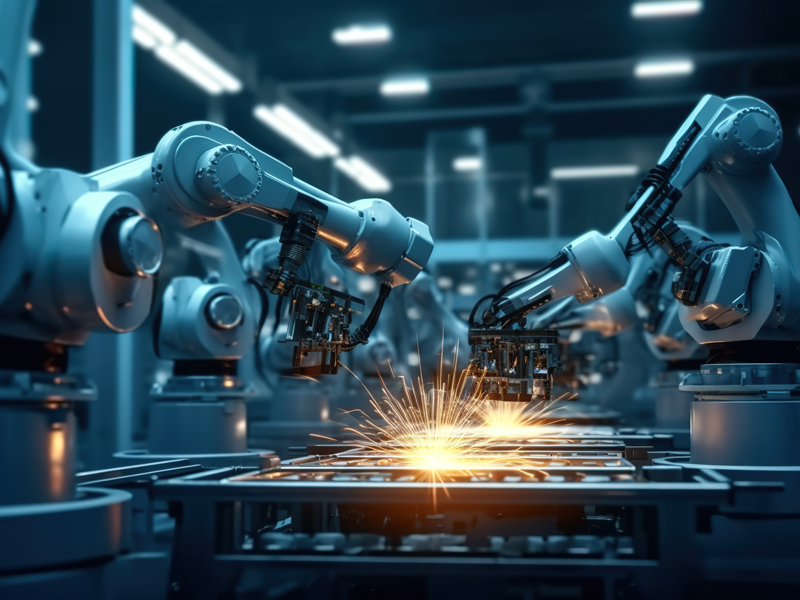

CAPEL Dedicated to Industry Control

Capel's printed circuit boards (PCBs) are vital for industry control systems due to their reliability, compact design, enhanced performance, quick prototyping, customization, cost-effective manufacturing, easy maintenance and repair, and compatibility. They enable the integration of components in a compact and organized way, resulting in improved performance and accurate signal flow. Capel's PCBs also allow for rapid prototyping and customization to meet specific industry control requirements. With automated manufacturing processes, Capel's PCBs enable cost-effective production in large quantities. They simplify troubleshooting and maintenance, as well as facilitate seamless communication and integration between various parts of the control system. Ultimately, Capel's PCBs contribute to efficient, reliable, and advanced industry control systems.

CAPEL Dedicated to IOT

Capel's Printed circuit boards (PCBs) are critical components in the development of Internet of Things (IoT) devices. They enable the integration and miniaturization of electronic components, ensuring efficient signal transmission and customization options. Capel's PCBs also help improve manufacturing efficiency and power optimization of IoT devices. Overall, Capel's PCBs provide a platform for simplified design and reliable functionality, which are critical to the successful implementation of IoT.

CAPEL Dedicated to Avionics

CAPEL's PCBs are widely used in avionics systems to improve performance, reliability and safety.

Capel's PCBs play a vital role in reducing the size and weight of electronic components, making aircraft lighter and more fuel efficient. They allow functionality to be integrated onto a single board, reducing complexity.

These circuit boards are designed to withstand harsh environmental conditions such as extreme temperatures, vibration, and electromagnetic interference to ensure reliable operation of aircraft systems.

Additionally, Capel's PCBs are capable of transmitting high-speed signals with low noise interference, thereby improving the overall performance and functionality of avionics systems.

They also promote easier maintenance and faster troubleshooting through modular design and standardized components. This minimizes downtime and increases aircraft availability.

Also, the cost-effectiveness of Capel's PCBs is an advantage. Mass production, simplified assembly and reduced component count help reduce manufacturing costs for the aerospace industry.

CAPEL Dedicated to Security

Capel's PCBs play a vital role in the development of secure systems by supporting the integration of security functions, facilitating secure design practices, hosting intrusion detection and prevention systems, incorporating trusted platform modules, enhancing connectivity security, and ensuring compliance with security standards. Overall, Capel's PCBs contribute to the security of a system by providing the basis for a secure hardware design and preventing unauthorized access, tampering, and data leakage.

CAPEL Dedicated to Drones

Capel's Printed circuit boards (PCBs) are crucial for the development of drones. They provide electrical connections, miniaturization, customization, signal integrity, reliability, and scalability. Capel's PCBs enable the connection of various electronic components and help make drones compact and lightweight. They also allow for customization based on specific requirements and ensure excellent signal transmission. Capel's PCBs are designed to withstand harsh environments and contribute to the overall reliability and durability of drones. Furthermore, Capel's PCBs enable scalability and innovation by allowing for updates and the incorporation of new technologies. In summary, Capel's PCBs are essential building blocks that enhance the functionality and performance of drones.

Aerospace

1. Material selection: FPCBs require high-quality, reliable materials with excellent thermal stability, such as polyimide (PI) or liquid crystal polymer (LCP), to withstand extreme temperature changes in aerospace environments.

2. Signal integrity: Given the length of the FPCB, signal integrity becomes critical. Advanced signal transmission techniques such as controlled impedance, differential signaling and shielding can be employed to minimize signal attenuation and maintain high reliability of data transmission.

3. High flexibility and bendability: FPCB should have excellent flexibility and bendability to accommodate curved or irregular shapes within aerospace systems. This will require careful attention to substrate material, copper thickness and trace routing to ensure that the FPCB can withstand repeated bending and flexing without loss of functionality.

4. Vibration and shock resistance: Aerospace applications, especially those involving air or space travel, are subject to high levels of vibration and shock. FPCB should be designed with appropriate reinforcement materials, including adhesives, ribs, and through-hole vias, to enhance its mechanical strength and durability.

5. EMI/RFI Shielding: Aerospace environments typically have significant levels of Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI). Combined with proper shielding techniques, such as the use of conductive or ground planes, it can help mitigate the effects of EMI/RFI and ensure that the performance of the FPCB is not affected.

6. Thermal management: Heat dissipation is a key consideration in aerospace applications. The FPCB should contain thermal vias, heat sinks or other cooling mechanisms to manage and dissipate the heat generated by the components. This will help prevent overheating and maintain reliable operation of the FPCB and related components.

7. Environmental Resistance: Aerospace systems are exposed to various environmental elements such as moisture, chemicals, and extreme temperatures. FPCBs should be designed with protective coatings and materials that are highly resistant to these factors to ensure long-term reliability and functionality.

8. Size and weight considerations: Although the length of the FPCB is specified as 15 meters, special care needs to be taken to keep the weight and thickness of the FPCB as low as possible. This is critical in aerospace applications where reducing weight is critical to improving fuel efficiency and meeting strict weight restrictions.

9. Testing and Quality Control: Given the critical nature of aerospace applications, an extensive testing and quality control process should be implemented during the production of FPCBs. This will involve rigorous electrical and mechanical testing to ensure compliance with industry standards and customer requirements.

10. Compliance with aerospace regulations: FPCB should comply with all relevant aerospace regulations, standards and certifications to ensure its suitability and safety in aerospace applications.

Designing and manufacturing a special, extra-long FPCB of 15 meters for aerospace applications requires expertise in materials, manufacturing techniques, and industry-specific standards. Working with an experienced PCB manufacturer specializing in aerospace applications is critical to achieving the required performance, reliability and compliance.