Customized 6-layer industrial equipment flex PCB-Case

| Technical requirements | ||||||

| Product type | Multi Flexible Printed Circuit Board | |||||

| Number of layer | 6 Layers | |||||

| Line width and line spacing | 0.1/0.1mm | |||||

| Board thickness | 0.25mm | |||||

| Copper Thickness | 12um | |||||

| Minimum Aperture | 0.15mm | |||||

| Flame Retardant | 94V0 | |||||

| Surface Treatment | Immersion Gold | |||||

| Solder Mask Color | Black | |||||

| Stiffness | FR4 | |||||

| Application | Industry Control | |||||

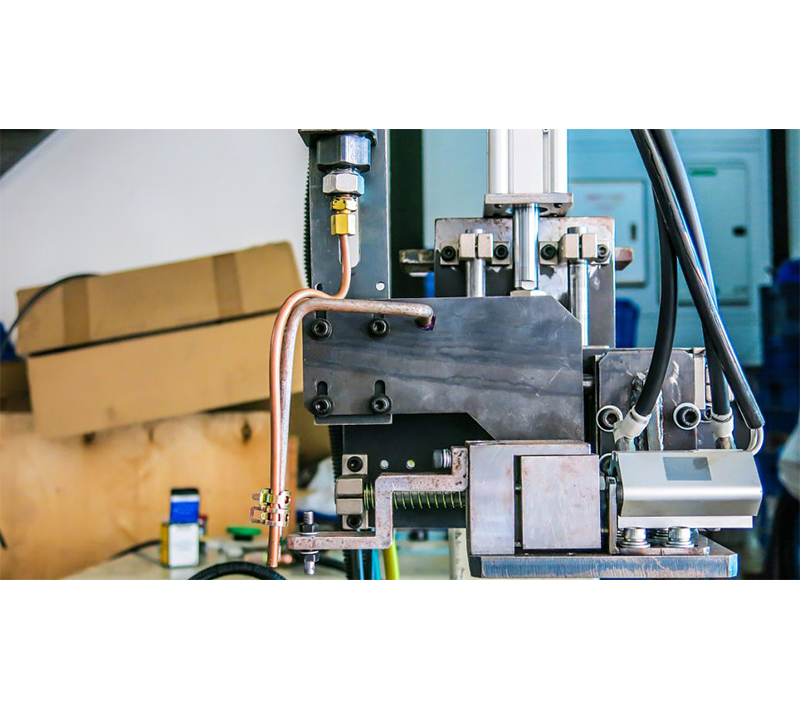

| Application Device | Industrial Equipment | |||||

Case Analysis

Capel's 6-layer flexible printed circuit board (PCB) is a cutting-edge product for the industrial control field, especially for industrial equipment applications. This case analysis will analyze various parameters of the product, highlight technological innovation points, and propose solutions to technical problems to promote the further improvement of the industry and equipment.

Line width and line spacing:

Capel's flexible PCBs feature excellent line widths and 0.1mm line spacing. This parameter demonstrates Capel's technical expertise in achieving high precision and fine detail in circuit design. Narrow linewidths and spacing enable the construction of complex circuits, ultimately improving performance and functionality.

Technology Solution:

To further enhance line width and spacing capabilities, Capel can invest in advanced manufacturing technologies and equipment to enable finer line widths and spacing. This improvement will meet the industry's growing demand for miniaturization and support the development of more advanced, compact electronic devices.

Board thickness:

Capel's 6-layer flexible PCB has a board thickness of 0.25mm. This parameter demonstrates Capel's technological innovation in enabling thinner, more flexible circuit boards. The board's slim profile facilitates easy integration into space-constrained applications without compromising durability.

Technical solutions:

To address potential technical issues related to board thickness, Capel can explore advanced materials and technologies that provide greater flexibility without compromising durability. Working with material suppliers to develop thinner but stronger materials can further optimize the performance of Capel flexible PCBs to meet the changing needs of the industry.

Copper thickness:

Capel's flexible PCB has excellent electrical conductivity and the copper thickness is 12um. This technological innovation ensures reliable signal transmission and power distribution in industrial control applications and industrial equipment, helping to enhance performance and functionality.

Technical Solution:

To meet industry demand for higher power, Capel could consider offering different copper thicknesses. The introduction of thicker copper options will accommodate greater current capabilities, allowing flexible PCBs to adapt to a wider range of industry and device requirements.

Minimum aperture:

Capel's 6-layer flexible PCB has a minimum hole diameter of 0.15mm, demonstrating precise drilling capabilities during the manufacturing process. This technological innovation enables precise interconnection and placement of components in circuit designs, ensuring optimal functionality.

Technology solution:

To meet future industry trends, Capel can invest in advanced laser drilling technology. Laser drilling offers greater precision and can create smaller apertures without compromising quality. This advancement will support the development of more complex and compact circuit designs to meet the demand for miniaturization.

Non-flammable:

Capel's 6-layer flexible PCB has an impressive 94V0 flame retardant rating. This technological innovation ensures compliance with the industry's strict safety standards. Flame retardant properties prevent circuit boards from starting fires and mitigate risks associated with electrical equipment.

Technical solution:

Capel can continuously improve flame retardant performance by exploring advanced flame retardant materials in collaboration with material suppliers. These materials will provide enhanced protection without compromising other properties such as flexibility and durability. This improvement will meet the industry's growing demand for highly reliable and secure electronic components.

Surface treatment:

The immersed gold surface treatment on Capel flexible PCBs improves the circuit's conductivity and corrosion resistance. This technological innovation ensures long-term reliability and high-quality signal transmission, helping to improve the performance of industrial control applications.

Technology Solutions:

Capel can continuously optimize and expand the range of custom surface treatment options to meet specific industry requirements. For example, introducing surface treatments with enhanced solderability or increased resistance to harsh environments will meet the unique needs of different industries and equipment, ultimately increasing customer satisfaction.

Post time: Sep-09-2023

Back