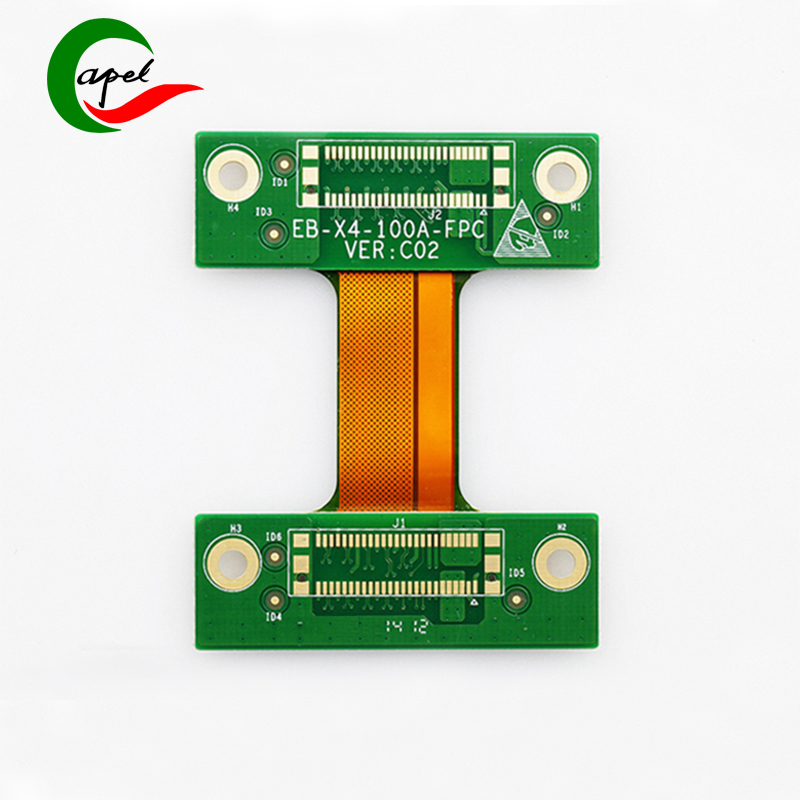

Industrial Control Industrial PC FPC

A short introduction:

Type: Industrial Control Industrial PC FPC

Minimum Line Width/Line Spacing: 0.13mm/0.12mm

Number of Layers: 3 Layer Rigid plus 2 Layer Flexible

Thickness: 1.6mm

Surface Finish: Immersion Gold

Kaboer's Service:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layer Rigid-Flexible Circuit Boards, 1-60 Layer Rigid PCB, Reliable Rapid turnaround PCB prototyping, rapid SMT PCB assembly

Industries We Serve:

Medical devices, IoT, TUT, drones, aerospace, automotive, telecom, consumer electronics, military, aerospace, industrial control, AI, electric vehicles, etc. ......

If you have related needs, please feel free to send us an email by clicking the button below.

Type: Rigid-flexible FPC for industrial control industrial computers, adopting “3-layer hardboard + 2-layer softboard” composite structure, designed for complex connection of industrial-grade equipments, adapting to core scenarios such as motherboards and IO interfaces, expansion modules and sensors, heat dissipation modules and control chips. Whether it is embedded industrial computer (installation space ≤ 100mm x 100mm), edge computing gateway (need to connect multiple sensors), or vibration-resistant industrial flat panel (for production line monitoring), can be stabilized through the hard plate area to carry BGA chips, HDMI interfaces, and other components, and at the same time through the flexibility of the soft plate area bending (the minimum bend radius R = 3mm), to adapt to the equipment of the irregular internal space (such as chassis corners, modules, and so on), and the design is specifically designed for the complex connection of industrial-grade equipment. At the same time, through the flexible bending of the soft board area (minimum bending radius R=3mm), it can be adapted to the irregular space inside the equipment (such as the corner of the chassis and the gap between the modules), replacing the traditional cable + rigid PCB combination, reducing the connecting nodes (reducing the risk of failure by 30%), and improving the system integration.

Minimum line width/spacing: 0.13mm/0.12mm industrial-grade high-precision standard. This parameter is optimized for the parallel transmission of multiple signals in industrial control scenarios: 0.13mm line width ensures that high-speed differential signals (e.g., EtherCAT, USB 3.0) are transmitted with lower loss (attenuation rate ≤0.2dB/m@100MHz) and meets the demand for low latency for real-time control (latency ≤1ms); 0.12mm line spacing realizes high-density wiring (≥40 lines per cm2 ) in limited space and supports system integration. ≥40 lines per square centimeter), supports parallel layout of power, signal and ground lines, reduces crosstalk between different signals (crosstalk rejection ratio ≥65dB), and avoids data packet loss caused by electromagnetic interference of motors and frequency converters in industrial environment (packet loss rate ≤0.01%).

Layers and structure: 3-layer hardboard + 2-layer softboard composite design, through layered functional isolation to achieve the dual goals of “stability + flexibility”:

3-layer hardboard area: FR-4 substrate to enhance the structural strength (bending strength ≥150MPa), can carry BGA packaged chips (eg, CPU, memory), board-to-board connectors ( Spacing ≤ 0.8mm), through multi-layer wiring to realize the separation of the power layer and signal layer, to reduce power supply noise (ripple ≤ 20mV), to protect the stable operation of the core chip;

2-layer flexible board area: the use of high toughness PI substrate, support for dynamic bending (can withstand 100,000 times ± 90 ° bending), connecting the hardboard and external modules (such as sensors, displays), and its flexible characteristics can absorb the vibration energy of equipment ( vibration frequency of 10-2000Hz). Its flexible nature absorbs the vibration energy of the equipment (vibration frequency 10-2000Hz) and prevents the rigid connection from loosening during vibration.

The transition zone between rigid and flexible is stepped, with reinforcing materials (e.g. PI tape) to strengthen the connection and ensure that stresses are dispersed during bending (stress concentration factor ≤ 1.2).

Thickness: Optimized thickness of 1.6mm, perfect balance between “structural support” and “spatial adaptation”. The hard plate area (thickness 1.6mm) provides sufficient strength to carry components (e.g. no deformation when the insertion and extraction force of 100pin connector is ≥50N); the soft plate area (thickness ≤0.3mm) maintains the thin and light flexibility, and can pass through the narrow channel inside the equipment (width ≥5mm), which is suitable for the compact and modularized design of the industrial computers (e.g. the stacked expansion module).

Surface treatment: the use of immersed gold technology (nickel layer thickness ≥ 5μm, gold layer thickness ≥ 0.05μm), bringing multiple industrial-grade advantages:

gold layer of excellent electrical conductivity, contact resistance of ≤ 20mΩ, to ensure the transmission of high-frequency signals (eg, Gigabit Ethernet) to ensure stability and reduce the BER of the data transmission (BER ≤ 10-¹ ²);

immersed gold plating layer of corrosion-resistant, can be resistant to industrial Workshop oil, dust, humid environments (through 96 hours of neutral salt spray test without corrosion), to adapt to the harsh scenes of 95% relative humidity (no condensation);

to enhance the reliability of the solder joints to ensure that the connector, the chip pins of the soldered parts of the - 40 ° C ~ +125 ° C temperature cycle without cracking (through the 1,000 times the temperature change test), to extend the service life of the equipment (MTBF ≥ 100,000 hours). (MTBF≥100,000 hours).

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..