Advanced 4 layer FPC Flex Boards fabrication Fab for Intelligent Kitchen

How Capel's Advanced 4 Layer FPC Flex Boards Fabrication Fab Provides Reliability Solutions for Intelligent Kitchen manufacturers

-Capel with 15 years of professional technical experience-

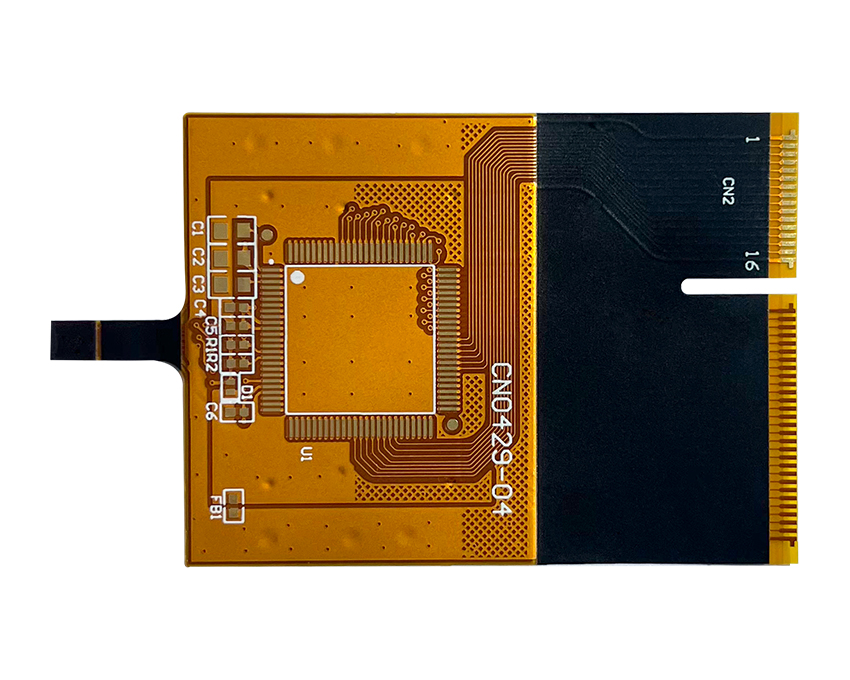

Launched new 4-layer FPC flexible board suitable for smart kitchens

We are pleased to announce the launch of our latest product – a 4-layer FPC flex board designed for smart kitchen applications. At Capel, we leverage 15 years of experience in manufacturing rigid-flex PCBs, flexible PCBs and HDI PCBs to create high-quality, reliable and cutting-edge solutions for the kitchens of the future.

Smart kitchens are revolutionizing the way we cook and interact with our cooking spaces. From smart appliances to voice-activated controls, technological advancements have brought convenience, efficiency and innovation to our home cooking experience. Our 4-layer FPC flexible boards are intelligently designed to integrate seamlessly into these smart kitchens, providing the necessary functionality and durability to support future cooking.

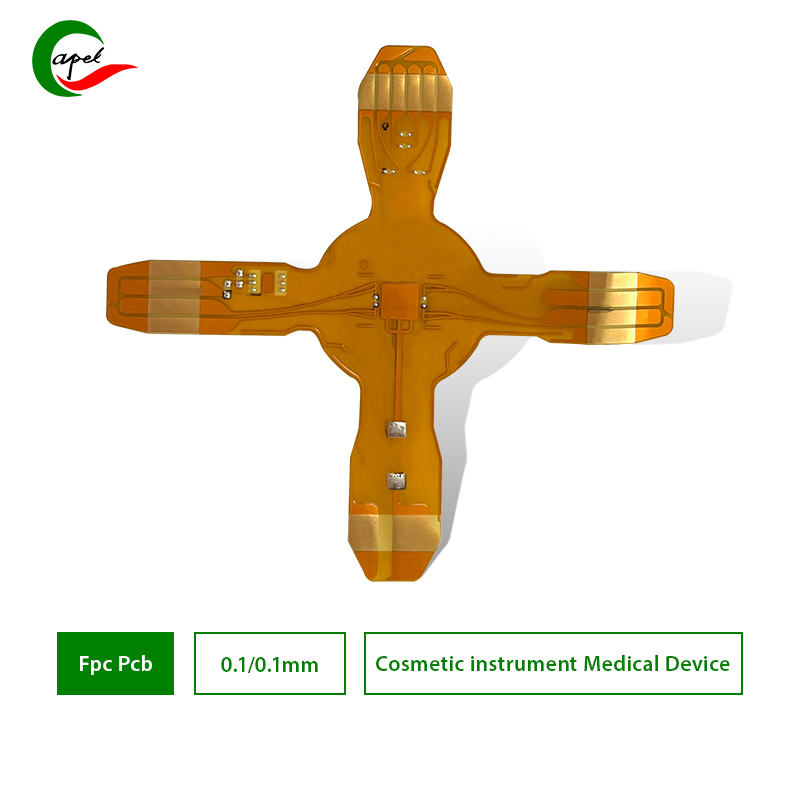

One of the outstanding features of our 4-layer FPC flexible boards is their excellent performance in terms of line width and line spacing. Featuring 0.1mm/0.1mm line width and line spacing, these boards provide superior precision and accuracy, ensuring optimal signal transmission and connectivity in smart kitchen settings. Whether controlling the temperature of a smart oven or adjusting the settings of a smart refrigerator, our motherboards enable seamless communication between various devices in the kitchen.

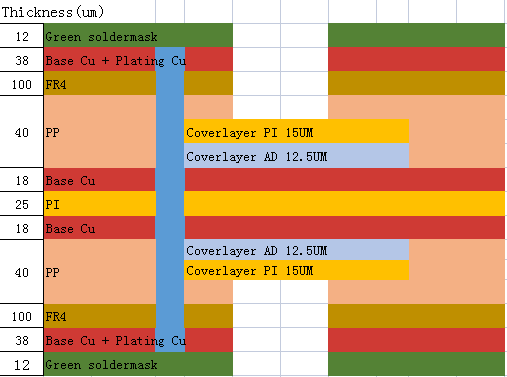

Equally important is the board thickness, which is only 0.2 mm. This ultra-thin design not only saves space, but also allows for greater flexibility and adaptability. With a minimum aperture of 0.3 mm, our 4-layer FPC flexible boards are capable of accommodating complex circuits and are ideal for compact and complex layouts commonly found in smart kitchen appliances.

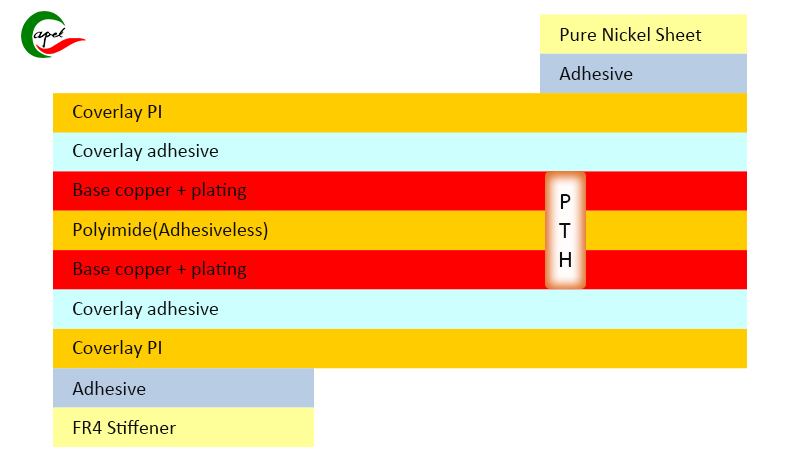

To further improve its performance, our boards have a copper thickness of 12um. This provides optimal electrical conductivity, helping to minimize interference and ensure reliable, efficient operation of kitchen appliances. Additionally, the stiffness of boards made of PI contributes to their durability and longevity, even in harsh kitchen environments.

Our 4-layer FPC flexible board also undergoes immersion gold surface treatment, which not only enhances the appearance, but also prevents oxidation, ensuring its long-term reliability. Additionally, these boards have achieved a 94V0 flame retardant rating, providing extra safety and protection for your smart kitchen setup.

As with all of our products, 4-layer FPC flex boards undergo strict quality control measures to ensure they meet the highest industry standards. Our strict quality control process guarantees that each board meets your exact specifications, making it the perfect choice for custom PCB solutions.

At Capel, we pride ourselves on our extensive project experience across a variety of industries. Our expertise in fast and reliable PCB prototyping enables us to deliver best-in-class products within tight deadlines. In addition, we also provide one-stop PCB SMT assembly services to further simplify our customers' manufacturing process.

In short, our 4-layer FPC flexible board is an ideal solution for future smart kitchens. With their outstanding performance, precise specifications and robust design, they are ideally suited to the demanding requirements of smart kitchen appliances. Trust Capel to provide you with the highest quality flexible PCBs and experience the difference our products can make in your smart kitchen setup. Please contact us today to discuss your specific requirements.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

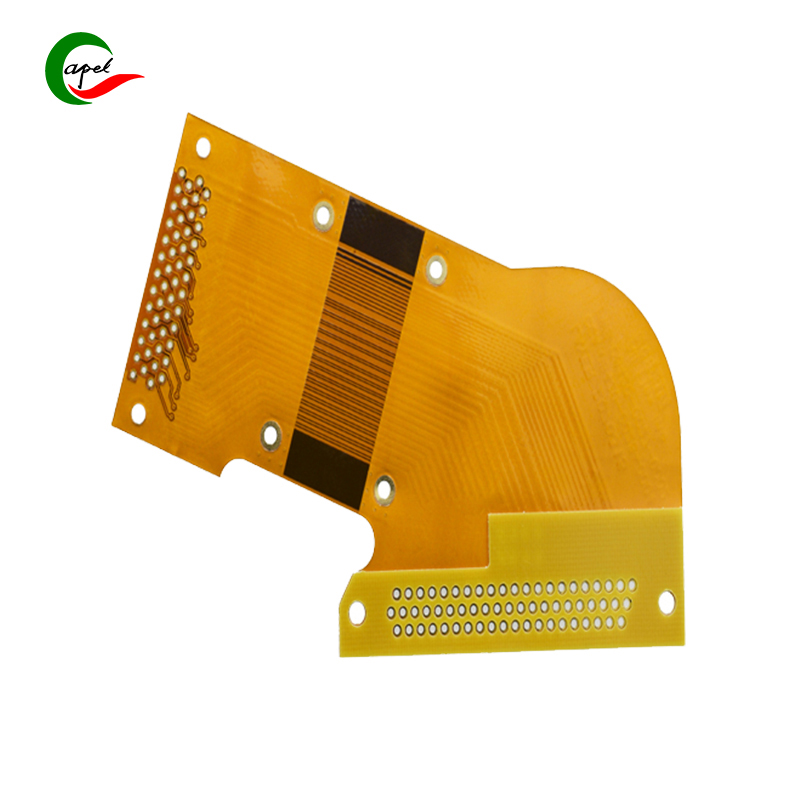

2 Layers Double-sided Fpc Pcb

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.