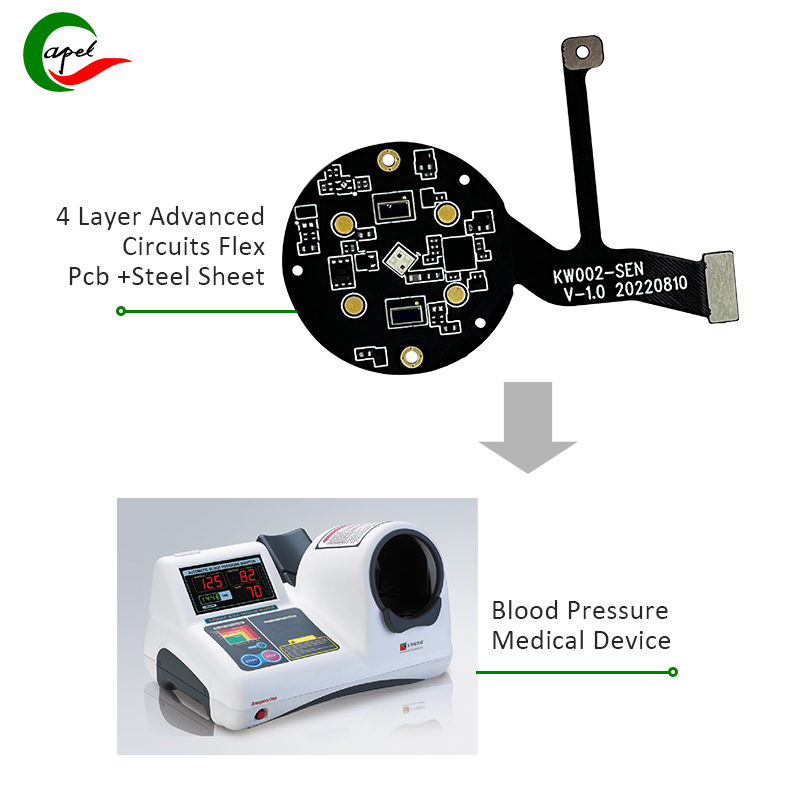

In the world of medical devices, technology plays a vital role in improving accuracy, efficiency and reliability. Among various advancements, the use of advanced circuits and flexible PCBs has dramatically changed the medical industry. Here we’ll explore how 4-layer PCB technology can support blood pressure medical devices.

One of the main properties of a 4-layer PCB is its stiffness, especially in the case of steel sheet based circuits. Stiffness is an important consideration for medical devices as it ensures product stability and durability. Accuracy is critical when it comes to blood pressure monitoring equipment. The use of steel plates in the PCB increases the rigidity of the circuit, preventing any bending or bending that could affect the accuracy of the blood pressure reading.

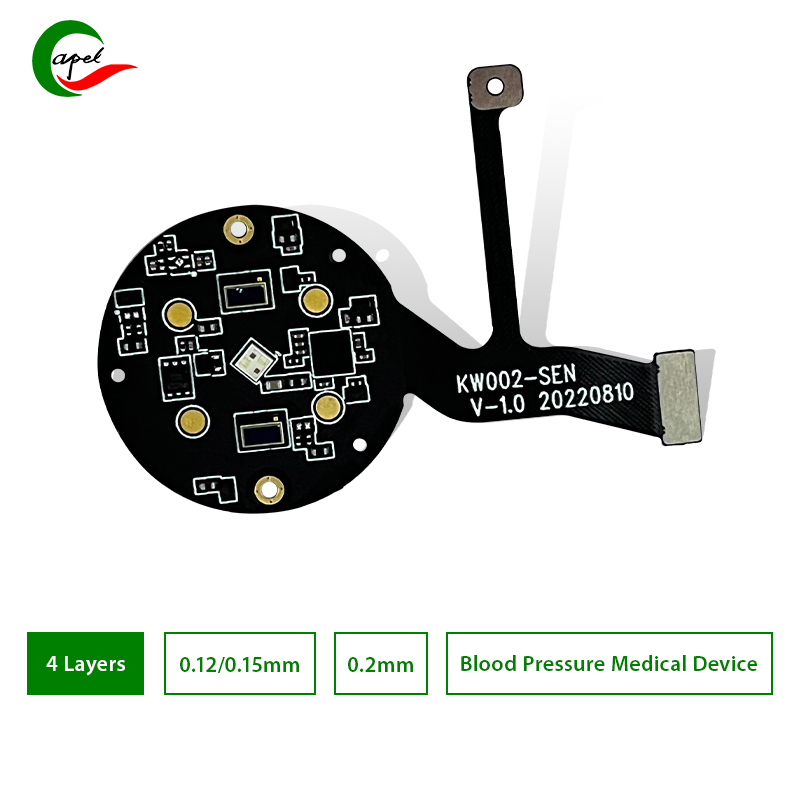

Advanced Circuits Flex PCB is a 4-layer PCB that offers many advantages for medical devices, especially blood pressure monitoring. Let’s take a closer look at the characteristics of this particular PCB type:

1. Number of layers: The 4-layer PCB configuration provides a higher level of integration for blood pressure monitoring devices. Additional layers provide more space for routing and placing components, allowing for the integration of multiple sensors and data processing functions on the board. This allows the device to collect data from various sensors such as pressure sensors and heart rate sensors, and accurately process the data to obtain accurate blood pressure readings. The 4-layer configuration also helps minimize signal interference, improving the overall performance and reliability of the blood pressure monitoring device.

2. Line width and line spacing: Line width and spacing on a PCB play a vital role in ensuring accurate signal transmission and minimizing the risk of interference. The 0.12mm line width and 0.15mm line pitch provide fine resolution for precise routing of signal traces on the PCB. In medical devices such as blood pressure monitors, accurate signal transmission is critical to obtaining accurate and reliable measurements. Any small change or disturbance in the signal can lead to inaccurate blood pressure readings, which can have serious consequences for the patient’s health. By using fine line widths and pitches, electrical signals can be transmitted accurately and efficiently. This helps minimize signal attenuation, crosstalk, and electromagnetic interference, ensuring the integrity of blood pressure measurements.

3. Board thickness: Choosing a board thickness of 0.2mm has several advantages when integrating a flexible PCB into a wearable blood pressure medical device. First of all, the thinner board thickness makes the PCB lighter. This is important for wearables as it ensures they don’t feel bulky or heavy when worn. The lightweight and flexible PCB contributes to user comfort, allowing individuals to easily wear the device for extended periods of time without discomfort. Additionally, the flexibility of the PCB allows it to bend and conform to the shape of the wearable device. This ensures a better fit and improves user comfort as the device adapts seamlessly to the contours of the body. This flexibility also reduces the risk of the PCB breaking or being damaged due to repeated bending or movement. The low profile profile of the PCB further enhances user comfort. By keeping the PCB thin, it reduces bulk that could be irritating or inconvenient to the wearer. The low-profile design ensures that the device remains discreet, making it less visible to others.

4. Copper thickness:The choice of copper thickness in the PCB plays a crucial role in ensuring efficient electrical conductivity and optimal signal transmission, which is especially important for accurate and reliable blood pressure measurement. In this case, a copper thickness of 35um (micrometers) is suitable to maintain a good balance between conductivity and flexibility. Copper is a highly conductive material with a thickness of 35um, which enables the efficient flow of electrical signals throughout the PCB traces. The efficient electrical conductivity provided by copper ensures that the blood pressure signal is accurately transmitted from the sensor to the device’s processing components. Any signal loss or distortion that may occur with insufficient conductivity can cause false readings and compromise the accuracy and reliability of blood pressure measurements. Additionally, proper copper thickness helps minimize resistance, impedance, and signal attenuation. This is especially important in sensitive applications such as blood pressure measurement, where even slight signal disturbances can significantly affect the accuracy of the readings.

5. Minimum aperture: The minimum aperture size of 0.2mm allows precise placement and integration of components on the flexible PCB. This ensures proper sensor and connector alignment for accurate data capture and transmission.Here’s how it ensures sensors and connectors are properly aligned for accurate data capture and transmission:

Component Placement:

Small aperture size enables precise positioning of components on flex PCBs. This is especially important for delicate sensors and connectors, as precise alignment ensures proper contact and function.

Sensor Alignment:

Inaccurate sensor alignment can lead to inaccurate data acquisition. The sensor has a minimum aperture size of 0.2mm and can be precisely aligned to ensure optimal contact with the target and accurate data measurement.

Connector Integration:

Connectors play a key role in transferring data between different components. The small aperture size allows for precise placement and alignment of the connector on the flex PCB. This ensures correct electrical contact and optimal signal transmission without loss or interference.

Reduced Signal Distortion:

Precise placement and integrated components through small aperture sizes help reduce signal distortion. This is especially important for flex PCBs, where bending and movement can affect signal integrity. Precise alignment minimizes the possibility of signal loss or attenuation during data capture and transmission.

6. Flame retardant: 94V0 flame retardant material is used to ensure the safety of the blood pressure monitoring device. In a medical environment where patient safety is paramount, the reliability and fire resistance provided by PCBs is critical.

In medical environments where patient safety is paramount, PCBs with flame retardant properties offer several advantages: Fire resistance:

94V0 flame retardant materials have the ability to prevent the spread of flames, prevent or suppress fires. This is especially important in medical settings where the presence of flammable materials or electrical faults can pose serious risks to patients and healthcare professionals. Using PCBs with flame retardant properties helps minimize the possibility of fire accidents.

Reliability:

PCBs with flame-retardant properties have higher reliability due to their ability to withstand high temperatures and fire resistance. In a medical environment, devices such as blood pressure monitors are subject to a variety of conditions, including high temperatures from the sterilization process or accidental exposure to heat sources. By using flame-retardant PCBs, the risk of damage or failure due to heat or fire is significantly reduced, ensuring reliable operation of equipment.

Compliance with safety standards:

Many regulatory agencies and standards organizations require electronic equipment used in medical environments to meet specific flame-retardant standards. By using 94V0 flame retardant materials in PCBs, medical device manufacturers can ensure compliance with these safety standards, improving the overall safety and compliance of blood pressure monitoring devices.

Protection of electronic components:

In addition to fire protection, flame-retardant PCBs also protect the electronic components mounted on them. The material’s fire-resistant properties help prevent component damage from heat or fire, maintaining the integrity and functionality of blood pressure monitoring devices.

7. Surface treatment: immersion gold surface treatment provides excellent corrosion resistance and solderability. This ensures PCB longevity and durability, even in challenging medical environments.

Here are some reasons why immersion gold finishes are beneficial, especially in challenging medical environments:

Corrosion resistance:

Immersion gold surface treatment forms a protective layer to protect the copper traces on the PCB from oxidation and corrosion. In medical environments, where exposure to moisture, chemicals and sterilization processes is common, corrosion resistance becomes critical. The immersion gold coating acts as a barrier from these harmful elements, ensuring the longevity and reliability of the PCB.

Solderability:

Copper, the main metal used in PCBs, is easily oxidized, reducing its solderability. The immersion gold finish forms a thin layer of gold on the copper traces, enhancing the solderability of the PCB. This facilitates the soldering process during PCB assembly, resulting in strong and reliable solder joints. Improving solderability is especially important for medical devices because consistent and durable solder connections are critical for optimal device function.

Lifespan and Durability:

The corrosion resistance provided by the immersion gold finish helps extend the life of the PCB. In a medical environment, where devices may be subjected to harsh conditions such as sterilization processes, chemical exposure or mechanical stress, PCB durability is critical. A protective gold layer ensures that the PCB can withstand these challenges and maintain its functionality and performance over an extended period of time.

Signal Integrity:

The immersion gold finish has excellent electrical properties, including low resistance and good signal transmission capabilities. This is important for medical devices such as blood pressure monitors that rely on accurate and reliable signal transmission. The gold layer on the PCB helps maintain signal integrity and reduces the risk of signal degradation or loss due to surface oxidation or poor solder joints.

Blood pressure monitoring devices utilizing 4-layer PCB technology offer several benefits to patients and healthcare professionals. The accuracy and reliability of blood pressure measurements contribute to better diagnosis and treatment decisions. The flexible and lightweight nature of the PCB makes the device suitable for long-term wear, thereby improving patient compliance.

The application of 4-layer PCB technology in blood pressure monitoring equipment demonstrates the great potential of advanced circuits and flexible PCBs in the medical industry. The combination of technological advancement and product features has provided great support for improving the accuracy, efficiency and reliability of blood pressure measurement.

The application of 4-layer PCB technology, especially through the rigidity of the steel plate composition, plays a vital role in supporting blood pressure medical devices. The advanced circuit flexible PCB provides an excellent platform for developing accurate and reliable blood pressure monitoring equipment with its specific product characteristics. As technology continues to evolve, we can expect further advances in medical devices driven by the integration of advanced PCB technology.

Post time: Sep-06-2023

Back