Discover how Capel’s custom solutions are revolutionizing aerospace electronics using advanced aerospace flexible PCB technology. Explore successful case studies showcasing Capel’s technology in solving industry-specific challenges and advancing aerospace PCB flex PCB prototyping and manufacturing Expertise in innovation

1. Introduction to Aerospace PCB-Flexible PCB Prototype Design and Manufacturing

In the fast-paced, demanding aerospace industry, the need for cutting-edge technology and innovative solutions is critical. As a seasoned flexible PCB engineer with 16 years of experience, I have witnessed firsthand the challenges aerospace companies face with flexible circuit board development and manufacturing. With an extensive project portfolio in aerospace flex PCB prototyping and manufacturing, I have come to appreciate the critical role that Capel’s custom solutions play in revolutionizing the aerospace industry through its advanced aerospace flex circuit board technology.

2. Challenges specific to the aerospace electronics industry

Capel’s custom solutions have always been at the forefront of technological innovation, providing custom solutions to solve the unique challenges faced by aerospace customers. In this article, we will delve into the successful case of how Capel aerospace flex PCB brings revolutionary changes, reflecting the company’s mature technology, strength, professionalism, advanced process capabilities, and strong R&D capabilities in aerospace flexible circuits and advanced technology circuit board prototyping and manufacturing.

Case Study 1: Enhancing Reliability and Performance of Aerospace Applications

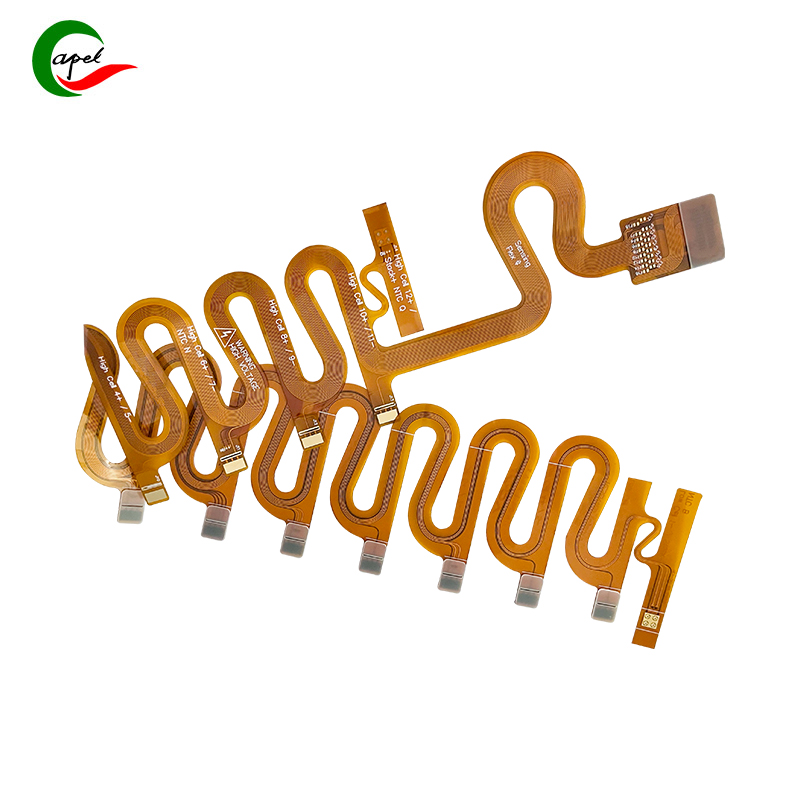

One of the major challenges in aerospace applications is ensuring the reliability and performance of electronic components under extreme environmental conditions. Capel’s custom solutions worked with a leading aerospace customer to develop a double-layer flexible printed circuit board with a board thickness of 0.15mm and a copper thickness of 18um. The ultra-slim and lightweight design coupled with a 94V0 flame retardant rating makes it ideal for aerospace applications where weight and space constraints are critical.

The implementation of a 0.15mm minimum aperture and immersed gold surface treatment significantly enhances the board’s reliability and signal integrity, ensuring seamless performance in high-frequency and high-speed applications. The yellow resistance welding color provides clear visual identification and simplifies the assembly process in aerospace manufacturing facilities. The use of FR4 and PI materials provides the perfect balance of stiffness and flexibility, allowing the board to withstand the rigors of the aerospace environment without compromising performance.

Capel’s aerospace flexible PCBs are successfully integrated into customers’ aerospace systems, greatly improving reliability, signal integrity and overall performance. This custom solution not only meets stringent aerospace standards but exceeds customer expectations, setting a new benchmark for electronic reliability in aerospace applications.

4. Case Study 2: Accelerating time to market through custom Aerospace Flex PCB prototyping

In the fast-paced aerospace industry, time to market is a critical factor that determines the success or failure of a project. Capel’s custom solution worked closely with a prominent aerospace customer to accelerate the prototyping phase of a cutting-edge aerospace system. With advanced process capabilities and strong R&D expertise, the Capel team developed custom flexible PCB prototypes with line width and line spacing of 0.075/0.1mm that can be tailored to the customer’s specific requirements.

5. Capel’s customized solutions: technological innovation and advanced process capabilities in aerospace flexible pcb

The rapid prototyping process, combined with Capel’s deep understanding of aerospace applications, enables customers to accelerate development cycles and bring their innovative aerospace systems to market earlier. Seamless collaboration and agile methods demonstrate Capel’s commitment to providing aerospace customers with customized solutions that fit their unique project timelines and technical specifications.

6. Impact of Capel Aerospace Flexible PCB Technology

The successful case studies presented here highlight the transformative impact of Capel’s aerospace flexible PCB technology in solving industry-specific challenges and driving technological innovation in the aerospace sector. Every data point and performance metric in these case studies reflects Capel’s unwavering dedication to excellence, from advanced technology and process capabilities to seamless integration of custom solutions into aerospace applications.

Aerospace Flexible PCB Prototyping and Manufacturing Process Technology

7. Conclusion: Redefining aerospace electronics with Capel’s custom solutions

In summary, Capel’s custom solutions are a beacon of innovation in aerospace flexible PCB prototyping and manufacturing, providing custom solutions that redefine what is possible in aerospace electronics. With a relentless focus on technological advancement, professionalism and a customer-centric approach, Capel’s continues to shape the future of aerospace electronics, setting new benchmarks for reliability, performance and time-to-market efficiency.

Post time: Mar-12-2024

Back