Introduction :

The aviation industry has always been at the forefront of innovation and technology. From groundbreaking new aircraft designs to optimized onboard systems, the pursuit of enhanced safety and efficiency remains the same. In this digital age, the integration of avionics systems plays a vital role in ensuring the highest performance levels of aircraft. Prototype printed circuit boards (PCBs) customized for aircraft avionics systems have become a game changer, enabling faster development, improved customization and increased reliability.

1. Understand the significance of aircraft avionics systems :

Aircraft avionics system is the nerve center of modern aircraft and contains various electronic components and systems. These systems are responsible for basic tasks such as navigation, communications, flight control, weather monitoring and autonomous driving functions. As the demand for advanced capabilities continues to increase, the need for innovative and reliable avionics systems has become critical. This illustrates the importance of PCB prototyping for aircraft avionics systems.

2. Previous challenges faced by aircraft avionics system development :

Traditional methods of developing avionics systems often involve assembling and testing multiple subsystems separately, resulting in longer development cycles and higher costs. Additionally, integrating third-party avionics components sometimes creates compatibility issues that further delay the process. However, advances in technology have opened up new possibilities for PCB prototyping.

3. Advantages of aircraft avionics system PCB prototype design:

A. Customization: Prototyping allows the PCB design to be customized to meet the specific needs and requirements of the avionics system. This flexibility makes integration easier, reduces troubleshooting, and enhances overall system performance.

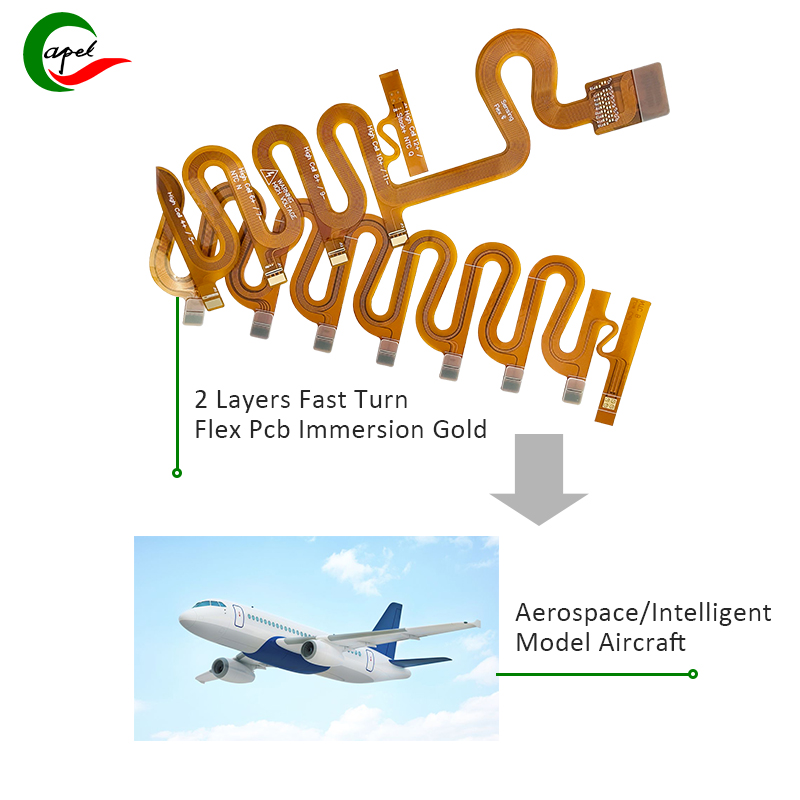

b. Rapid Development: PCB prototyping significantly speeds up the development process as it eliminates the need for external circuitry and simplifies the connection of components. Faster turnaround times enable manufacturers to identify and correct design flaws more efficiently while reducing time to market.

C. Error Identification and Correction: Prototyping allows avionics systems to be thoroughly tested before production, minimizing the risk of in-flight failure. By catching errors and defects early, manufacturers can implement necessary changes without causing delays or compromising safety.

d. Quality Assurance: PCB prototypes are rigorously tested to ensure they meet strict reliability and durability standards. Increased testing will not only improve the overall performance of avionics systems, but also improve flight safety.

4. Work towards safety and compliance :

Aircraft avionics systems must meet stringent safety and regulatory requirements from aviation authorities around the world. PCB prototyping of these systems allows manufacturers to verify and validate design and performance aspects, thereby promoting compliance. Through thorough testing, these prototypes demonstrate their efficacy, allowing manufacturers to meet regulatory obligations and provide a safe flying experience.

5. Embrace the possibilities of the future:

There are endless opportunities for advancements in future aircraft avionics systems. PCB prototyping enables rapid innovation, allowing researchers and engineers to try out novel ideas and designs. The ability to quickly iterate and test new technologies ensures the aviation industry remains ahead of the curve and continues to improve aircraft safety and efficiency.

Conclusion

PCB prototyping of aircraft avionics systems is a groundbreaking development that revolutionizes the way these critical systems are designed and developed. Advantages such as customization, rapid development, error identification and quality assurance make PCB prototyping an important tool for manufacturers working to improve safety and efficiency. By taking this revolutionary approach, the aviation industry can stay at the forefront of innovation and deliver safer, more technologically advanced aircraft to passengers around the world.

Post time: Oct-26-2023

Back