When it comes to moisture and moisture resistance, one may wonder whether rigid-flex PCBs can meet this challenge. In this blog post, we’ll delve deeper into this topic and explore the moisture and humidity resistance of rigid-flex PCBs.

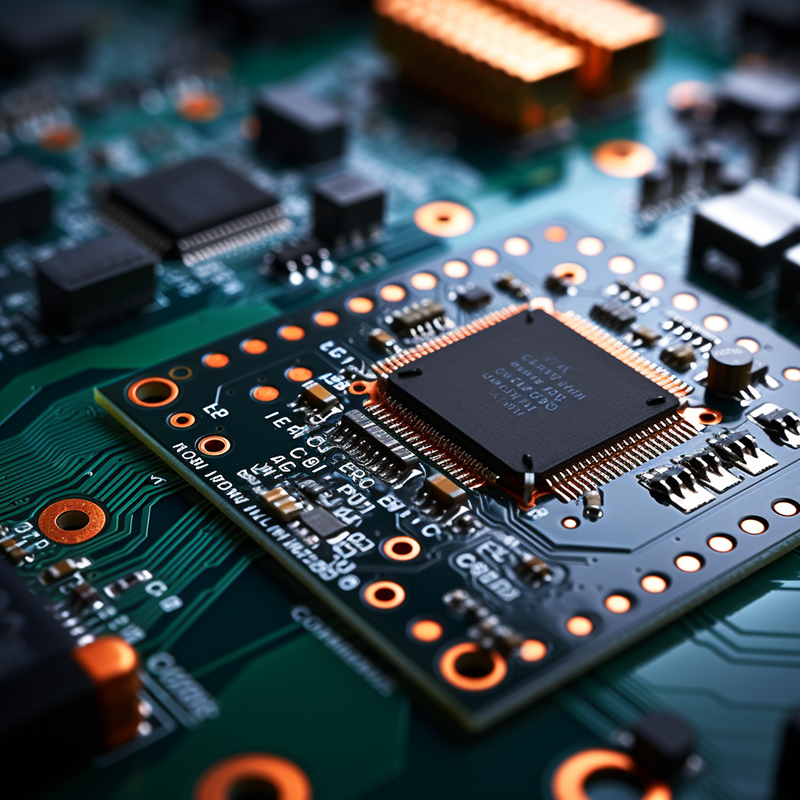

Printed circuit boards (PCBs) are the core of modern electronic devices,providing a platform for connecting and supporting various electronic components. PCB technology has evolved over the years, and one of these advancements has been the introduction of rigid-flex PCBs.These boards offer flexibility combined with the structural integrity of rigid boards,making them highly versatile and suitable for a wide range of applications.

Moisture and humidity are common environmental factors that can significantly affect the performance and reliability of electronic devices. Exposure to moisture can cause a variety of problems, including corrosion, electrical shorts, and deterioration of insulation.Therefore, it is crucial to ensure that PCBs used in devices are resistant to these factors, especially in applications where exposure to high humidity is likely.

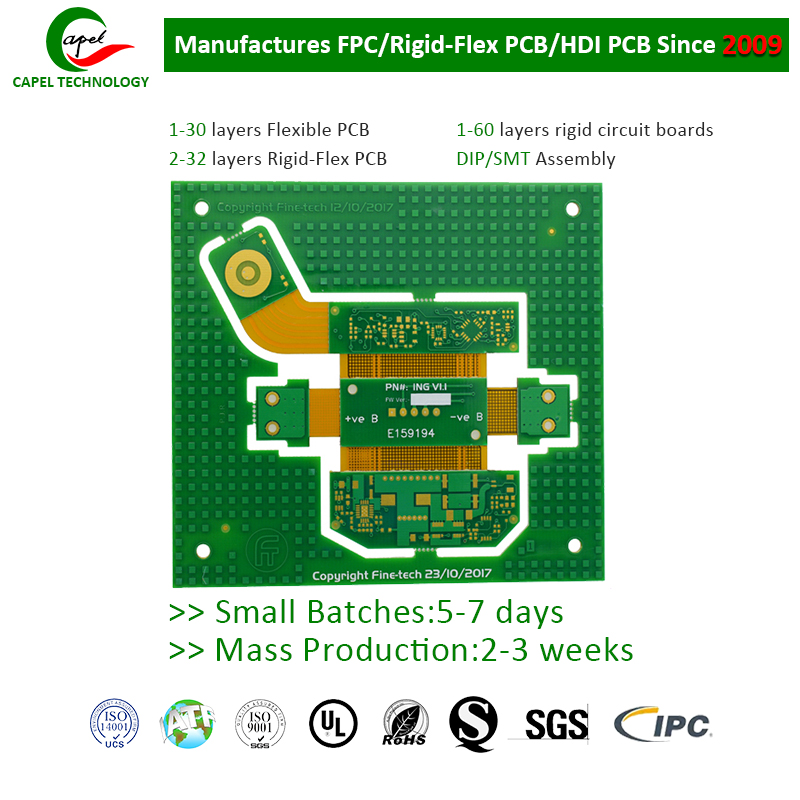

Rigid-flex PCB has a unique structure and has a certain degree of moisture and humidity resistance. These boards are typically made from a combination of flexible polyimide layers and rigid FR-4 layers, creating a strong and reliable circuit board. The polyimide layer provides flexibility, allowing the PCB to bend or twist as needed, while the FR-4 layer provides structural stability.

One of the main factors in improving the resistance of rigid-flex PCBs to moisture and humidity is the use of polyimide as the base material.Polyimide is a highly stable polymer with low moisture absorption and excellent moisture resistance.This property protects the integrity of the PCB by preventing the polyimide layer from absorbing moisture.Additionally, polyimide’s flexibility allows circuit boards to withstand certain environmental conditions without being affected by moisture.

In addition, the rigid-flex board is manufactured using advanced technology to enhance its moisture-proof and moisture-proof capabilities. These processes involve the application of a protective coating,such as a conformal coating or sealant, that acts as a barrier against moisture ingress.These coatings are specifically designed to prevent moisture from reaching sensitive electronic components and causing damage.

It is worth noting that although rigid-flex PCBs have significant moisture and humidity resistance, they are not completely immune to these factors. Extreme conditions, prolonged exposure to high humidity, or improper handling may still affect the performance of these boards.Therefore,the specific environmental requirements of a particular application must be considered and the PCB designed accordingly.

When designing the moisture resistance of rigid-flex PCBs, several factors should be considered.Adequate spacing between components, proper sealing of connectors and vias, and judicious use of moisture-proof materials are some of the key aspects that help increase PCB resistance to these environmental factors.Working closely with an experienced PCB manufacturer can ensure that the design is optimized to achieve the required level of moisture and moisture resistance.

In short,due to its unique structure and the use of moisture-proof materials such as polyimide,rigid-flex boards generally have good moisture-proof and moisture-proof properties.They provide a reliable solution for electronic equipment that may be exposed to harsh environmental conditions. However, it is important to consider the specific requirements of the application and design the PCB accordingly to maximize its ability to withstand moisture and humidity. By doing this, electronic equipment manufacturers can ensure the longevity and reliability of their products, even in demanding environments.

Post time: Sep-18-2023

Back