Advanced Circuits flexible PCBs are key components in many electronic devices. As electronic products become increasingly complex and compact, flexible PCBs have gained prominence in modern technology. However, ensuring the quality of these flexible printed circuit boards is critical to guaranteeing optimum performance and reliability. In this blog, we will explore various aspects that contribute to the excellence of Advanced Circuits flex PCBs. By knowing how to assess this quality, you can make an informed decision when selecting and incorporating these flex PCBs into your electronic designs.

1. Understand flexible PCB:

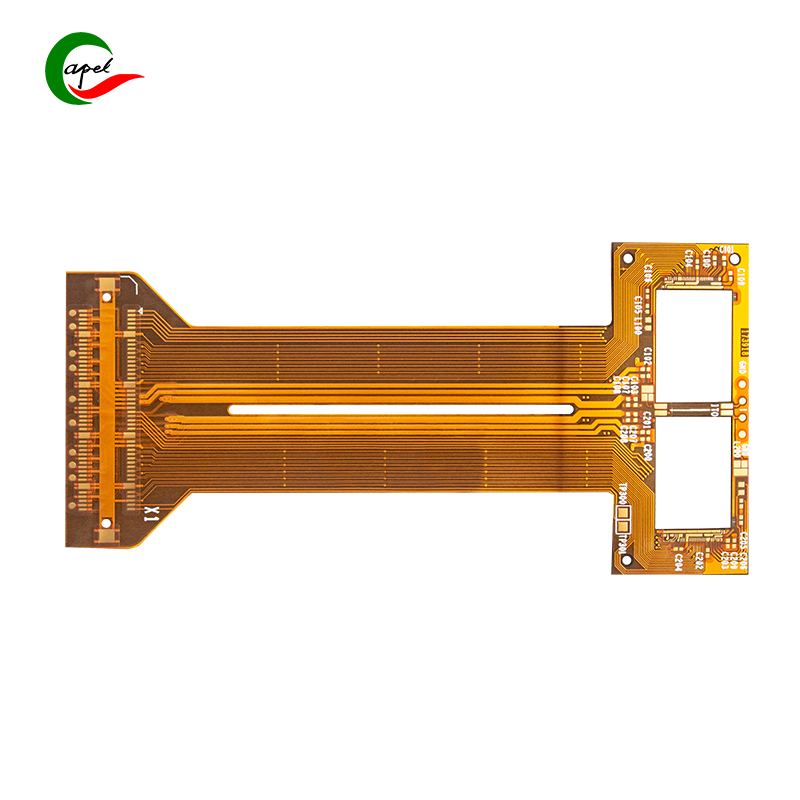

Before diving into evaluating the quality of Advanced Circuits Flex PCB, it is important to grasp the basic concepts. A flexible printed circuit board, as the name suggests, is a printed circuit board that can be bent or bent to fit unique or compact form factors. They are made from a flexible substrate material, such as polyimide, which allows them to be bent without compromising their electrical connectivity. Flexible PCBs offer several benefits, including increased design flexibility, improved reliability, and reduced size and weight.

2. Factors affecting the quality of flexible boards:

a) Material: The choice of material significantly affects the quality of the Advanced Circuits Flex PCB. High-quality substrates with excellent electrical, mechanical and thermal properties are essential for optimal performance and durability. Research materials used in flex PCBs, such as copper traces, laminates, and coverlays, to ensure they meet your specific requirements.

b) Manufacturing process: The manufacturing process plays a vital role in determining the quality of the flexible PCB. Advanced Circuitry employs state-of-the-art manufacturing techniques and protocols to ensure consistent and reliable production. Factors such as precise material preparation, controlled layer alignment, precise bonding, and effective soldering all contribute to improving the overall quality of flexible PCBs.

c) Dimensional Stability: Another important aspect of evaluating the quality of an Advanced Circuits Flex PCB is evaluating its dimensional stability. This refers to the ability of a flexible PCB to maintain its shape and size under various environmental conditions such as temperature changes or mechanical stress. Dimensional stability ensures that the flex PCB will perform reliably throughout its lifetime.

3. Electrical performance:

The electrical performance of an Advanced Circuits Flex PCB is critical in determining its quality and reliability. Here are some key factors to consider:

a) Signal Integrity: A high-quality flex PCB should minimize signal loss, noise, and interference to ensure optimal signal integrity. This can be achieved through proper trace routing, impedance control, and transmission line considerations during the design process.

b) Electrical testing: Strict electrical testing during production is essential to ensure the highest quality of flexible PCBs. Various tests such as continuity tests, insulation resistance tests and impedance measurements help identify any electrical faults or anomalies that may affect overall performance.

4. Reliability and durability:

The reliability and durability of Advanced Circuits flexible PCBs are critical for critical applications and harsh environments. Consider the following factors when evaluating its quality:

a) Environmental resistance: The flexible PCB should be resistant to moisture, chemicals, temperature and mechanical stress. Ensuring that the materials and construction techniques used in a flexible PCB are suitable for your specific application requirements is critical to maintaining its reliability.

b) Fatigue resistance: Flexible PCB needs to be bent or flexed repeatedly, so high fatigue resistance is required. A quality flex PCB should be able to withstand multiple flex cycles without degrading its electrical or mechanical performance. It is crucial to study the life expectancy of flexible PCBs under expected bending conditions.

c) Solder joint reliability: The quality of solder joints significantly affects the reliability of flexible PCBs. Robust solder joints with proper soldering techniques such as Surface Mount Technology (SMT) ensure long-term reliability and minimize the risk of faulty or intermittent connections.

Conclusion:

Evaluating the quality of Advanced Circuits flex PCBs is critical to ensuring optimum performance, reliability and longevity. By understanding the key factors that affect its quality, such as material, manufacturing process, dimensional stability, electrical performance, reliability, and durability, you can make an informed decision when selecting a flexible PCB for your electronic design. Partnering with a reputable and experienced flex PCB manufacturer like Advanced Circuits can further increase the odds of obtaining a high quality, reliable flex PCB for your application. Remember, an investment in quality today ensures the efficiency and longevity of tomorrow’s electronic equipment.

Post time: Sep-02-2023

Back