Introduce:

Capel is a professional circuit board manufacturer with 15 years of experience, recognized for solving cutting-edge problems for customers in a variety of industries. A common question we often get is whether Capel has the capability to prototype high current PCB boards. In this blog, we intend to address this issue in detail, clarifying our expertise and capabilities in meeting such specific requirements.

Learn about PCB prototyping:

Before delving into Capel’s precise technical capabilities, it’s important to have a clear understanding of PCB prototyping. PCB, or Printed Circuit Board, acts as a critical component in electronic devices by providing electrical connections between various components. Prototyping is the process of making a working model or preliminary version to test the functionality and features of a PCB design.

High current PCB board:

High current PCB boards are designed to handle and distribute large amounts of electrical current. These boards are frequently used in power supply units, motor drives, and other high-power applications that require superior skill and craftsmanship during the prototyping stage. Over the years, Capel has encountered many projects that required specialized PCBs that could withstand high currents while maintaining structural integrity.

Capel’s expertise in prototyping PCBs with high current capabilities:

Capel takes great pride in its ability to meet and exceed customer expectations, even when it comes to highly specialized requirements such as high current PCBs. Our team of experienced engineers and technicians have comprehensive knowledge and expertise in designing and prototyping PCBs with superior current carrying capabilities. We understand the unique challenges associated with these projects and have developed strategies to ensure the highest levels of accuracy and reliability.

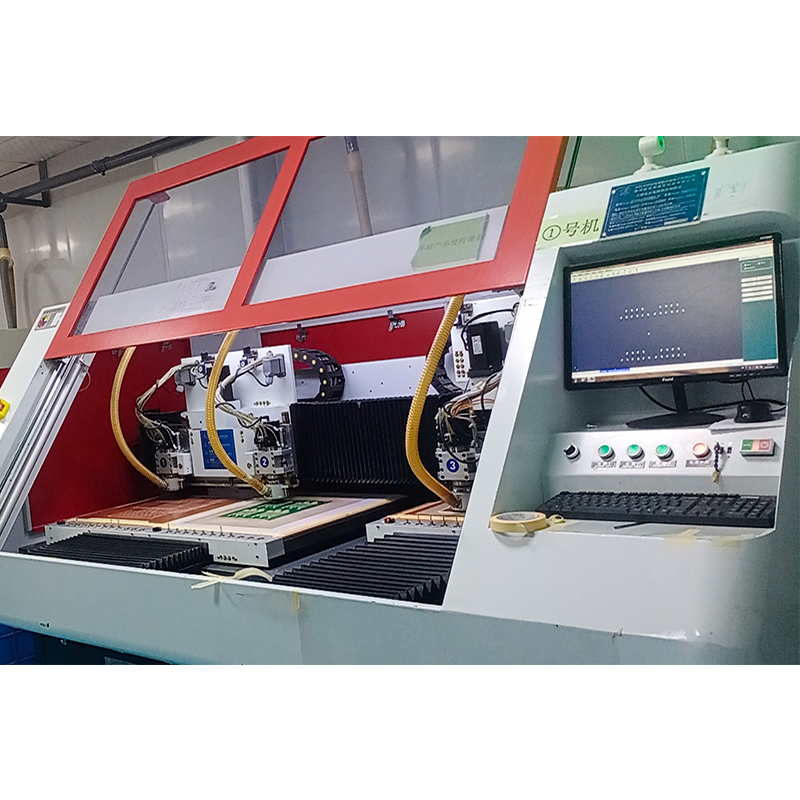

Advanced Manufacturing Technology:

At Capel, we utilize state-of-the-art manufacturing technologies to create high-current PCB prototypes. These technologies include the use of high-quality materials, strict quality control measures and advanced assembly processes. By combining our expertise with cutting-edge equipment, we can produce PCB boards that can efficiently handle and distribute high currents without compromising their structural integrity.

Thermal management:

One of the most critical factors to consider when prototyping high-current PCB boards is thermal management. Excessive heat generated by high currents can seriously affect the performance and lifespan of electronic devices. Capel specializes in implementing effective thermal management techniques through strategic placement of copper, heat sinks, vias, and proper solder mask design. By carefully managing heat dissipation, we ensure optimal performance and longevity of the PCB.

Robust design and material selection:

To meet the demands of high-current applications, Capel prioritizes robust design and careful material selection during the prototyping process. Our team carefully analyzes each project’s electrical and mechanical requirements to select the most appropriate materials and circuit board configurations. By selecting materials with sufficient copper thickness and low resistance, we can achieve higher current carrying capabilities without compromising structural integrity.

Reliability and performance testing:

To ensure the reliability and performance of our high-current PCB prototypes, Capel performs rigorous testing at every stage of the manufacturing process. Our quality control team uses a variety of testing methods, including thermal cycling, accelerated life testing and load testing, to simulate real-world conditions. By subjecting our prototypes to these tests, we ensure that they can withstand the harsh environments expected.

In conclusion:

With 15 years of experience as a professional circuit board manufacturer, Capel has the expertise and technical capabilities to prototype PCB boards with high current capabilities. Our commitment to utilizing advanced manufacturing techniques, prioritizing thermal management, and conducting thorough reliability and performance testing allows us to deliver high-quality PCBs that excel in high-current applications. Partner with Capel for your high-current PCB prototyping needs and experience our cutting-edge solutions that consistently meet the needs of various industries.

Post time: Oct-17-2023

Back