In this blog post, we’ll explore the benefits and challenges of using rigid-flex circuit boards in wearable technology applications.

Wearable technology has grown in popularity in recent years, with devices such as fitness trackers, smartwatches and even smart clothing being widely adopted. As the demand for smaller, more flexible and more powerful electronic components continues to grow, so does the need for innovative circuit board designs. A design called rigid-flex circuit boards shows great potential in meeting these requirements. But can rigid-flex circuit boards really be used in wearable technology?

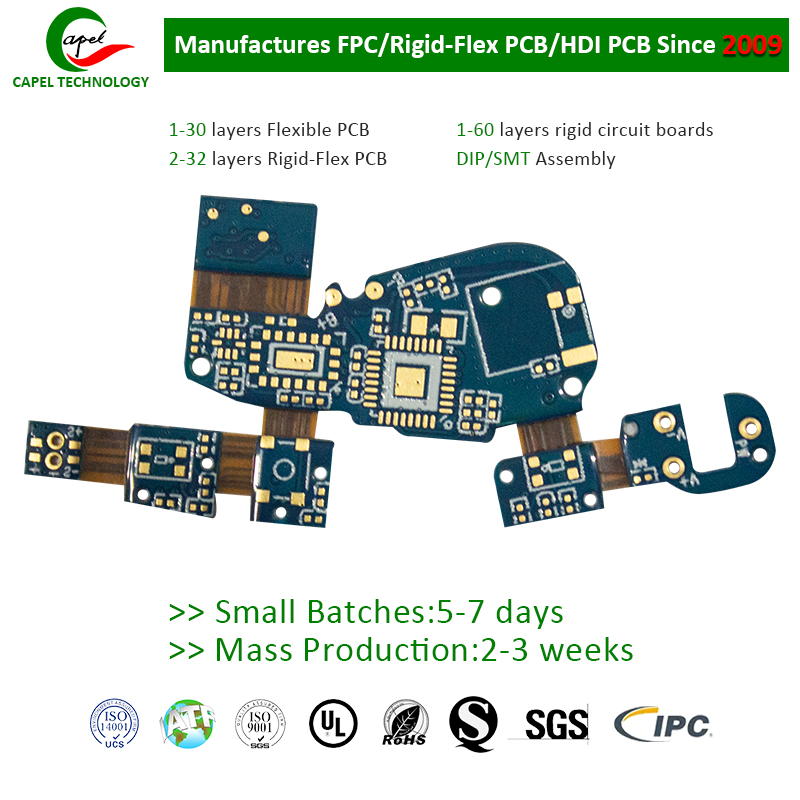

To understand why rigid-flex circuit boards are suitable for wearable technology, it’s important to first understand their basic characteristics. Rigid-flex boards combine the advantages of rigid and flexible circuits to enable three-dimensional designs that conform to the shape of wearable devices. They consist of multiple layers of flexible substrates, usually made of polyimide, connected by rigid sections. This combination results in a circuit board that is both rigid and flexible, providing the best of both worlds.

One of the main advantages of using rigid-flex circuit boards in wearable technology is their compactness. The panels can fold, twist or bend to fit into tight spaces, enabling the creation of stylish, lightweight wearable devices. Additionally, the elimination of bulky connectors and cables reduces the overall size of the device and makes it more comfortable for the wearer. Rigid-flex boards also offer a greater degree of design freedom, allowing manufacturers to create innovative and beautiful wearable technology products.

Another important aspect of wearable technology is durability. Because wearable devices are often subject to bending, stretching, and other physical stresses, the circuit boards used in them must be able to withstand these conditions. Rigid-flex boards excel in this area because the combination of rigid and flexible layers ensures that the circuit remains intact even under repeated movement. This durability is further enhanced by the use of a polyimide substrate known for its excellent mechanical and thermal properties.

In addition, rigid-flex circuit boards provide higher signal integrity compared to traditional flex circuits. The rigid portion of the circuit board provides stability and prevents signal degradation, ensuring reliable data transmission within the wearable device. This is critical for wearable technology applications that rely on accurate real-time tracking of biometric data or communication with external devices. Whether it’s heart rate monitoring, GPS tracking or wireless connectivity, the performance of wearable technology depends heavily on the robustness of its circuitry.

However, despite the numerous advantages that rigid-flex circuit boards bring, they also face considerable challenges. One major challenge is the complexity of the manufacturing process. The combination of rigid and flexible circuits requires specialized equipment and expertise, which increases production costs. Additionally, testing and quality control of rigid-flex boards can be more complex than traditional circuit boards because maintaining the integrity of rigid and flex components is critical.

Another consideration when using rigid-flex circuit boards for wearable technology is thermal management of the device. As wearable devices become more powerful and feature-rich, heat dissipation becomes critical to prevent component damage and ensure optimal performance. Rigid-flex boards can pose challenges when it comes to heat dissipation due to their multi-layer structure. Appropriate thermal management strategies, such as heat sinks or heat sinks, must be implemented during the design phase to effectively address this issue.

In summary, using rigid-flex circuit boards in wearable technology offers many advantages, such as compactness, durability, design flexibility, and signal integrity. These boards could create smaller, more comfortable, and better-looking wearable devices. However, manufacturers need to address challenges related to manufacturing processes, testing, quality control and thermal management. By overcoming these barriers, rigid-flex circuit boards have the potential to revolutionize the wearable technology industry and pave the way for more advanced and complex devices in the future.

Post time: Sep-20-2023

Back