In this blog post, we explore the potential of rigid-flex circuit boards in medical devices and discuss their benefits and challenges.

In recent years, advances in technology have revolutionized the field of healthcare. From robotic surgical systems to smart devices that monitor patient vital signs, technology continues to play a vital role in improving patient care. One technological innovation that has received widespread attention is the use of rigid-flex circuit boards in medical devices. These boards offer a unique combination of rigidity and flexibility, making them ideal for a variety of applications in the medical industry.

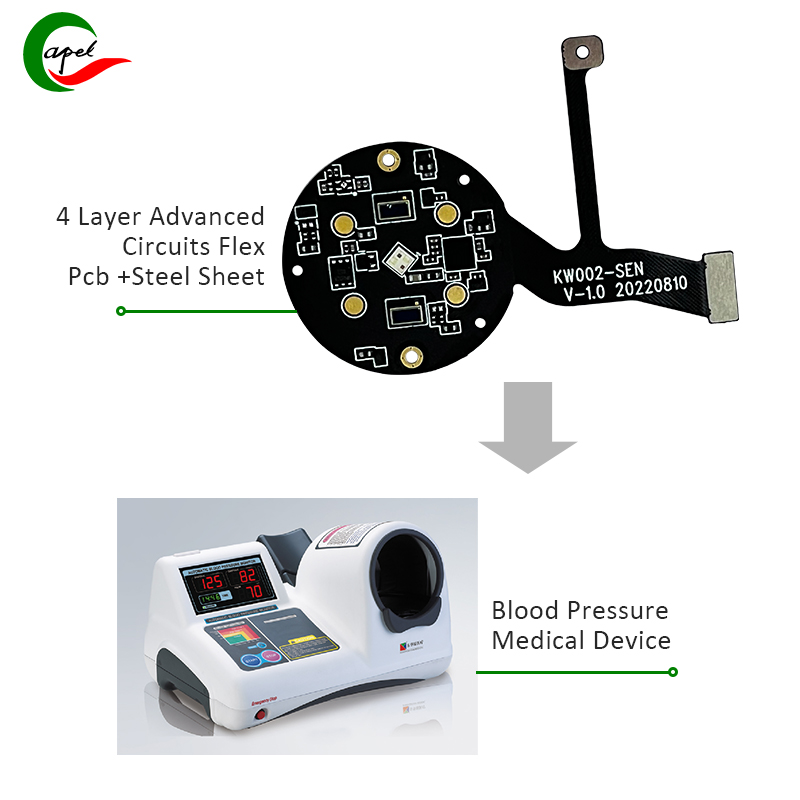

Rigid-flex board, as the name suggests, is a hybrid form of traditional rigid circuit board and flexible circuit board. They combine the best of both worlds, allowing engineers to design electronic devices that can withstand mechanical stress while being compact and lightweight. The flexibility of these boards makes it possible to create devices that can bend, twist, or conform to the contours of the human body. This feature has proven particularly useful for medical devices that need to be worn on or implanted in the body.

There are many advantages to using rigid-flex circuit boards in medical devices. First, these circuit boards allow medical devices to be miniaturized and more comfortable for patients to wear or carry. For example, wearable health trackers that monitor heart rate, activity levels, and sleep patterns require compact, lightweight designs. Rigid-flex circuit boards provide the necessary flexibility without compromising reliability or performance.

Second, rigid-flex circuit boards are highly reliable and reduce the risk of failure in critical medical applications. In the medical field, especially implantable devices, reliability is critical. Rigid-flex circuit boards are rigorously tested and adhere to strict quality standards to ensure that the equipment they are used in operates flawlessly. The combination of rigid and flexible materials provides the necessary durability to withstand the harsh and harsh environments found within the human body.

Additionally, using rigid-flex circuit boards allows engineers to design devices that are resistant to moisture, chemicals and temperature changes. This is especially important for medical devices that come into contact with body fluids or undergo a sterilization process. By utilizing appropriate materials and manufacturing techniques, rigid-flex circuit boards can withstand these challenging conditions and ensure the longevity of integrated medical devices.

Despite the many advantages, there are certain challenges associated with using rigid-flex circuit boards in medical devices. One of the challenges is the complexity of the manufacturing process. The complex design and assembly of these boards requires specialized knowledge and equipment. Medical device manufacturers must work closely with experienced PCB manufacturers to ensure successful integration of rigid-flex circuit boards into their devices.

Another challenge is the strict regulatory requirements of the healthcare industry. Medical devices must comply with strict regulations to ensure patient safety. The use of innovative technologies such as rigid-flex circuit boards adds additional complexity to the regulatory compliance process. Manufacturers need to understand the regulatory environment to obtain the necessary certifications and approvals before using their devices in clinical settings.

As the demand for smaller, more reliable and patient-friendly medical devices continues to grow, the potential of rigid-flex circuit boards in the healthcare industry becomes even greater. Their versatility, durability, and ability to be miniaturized make them an attractive choice for a variety of medical applications. From implantable devices to wearable sensors, rigid-flex circuit boards have the potential to transform the way healthcare is delivered.

In summary

Rigid-flex circuit boards offer a promising solution for medical device manufacturers seeking to create compact, reliable, and flexible electronic devices. Their unique combination of rigidity and flexibility enables the design of innovative medical devices that can withstand challenging environments and conform to the contours of the human body. Despite challenges in manufacturing complexity and regulatory compliance, the benefits of using rigid-flex circuit boards in medical devices outweigh the drawbacks. With further advancements in technology and increasing collaboration between PCB manufacturers and medical device companies, the future of integrating rigid-flex circuit boards into medical devices is bright.

Post time: Sep-18-2023

Back