Introduction :

In the world of circuit board manufacturing, ensuring traceability and quality assurance is critical. With 15 years of experience, Capel has become an industry leader. This blog post delves into Capel’s journey and explores their expertise in delivering high quality PCB boards while maintaining strict traceability standards. Join us to learn about the innovative practices and technologies Capel uses to deliver its clients an unwavering commitment to excellence.

1. The importance of PCB circuit board traceability:

Traceability plays a vital role in ensuring the integrity and reliability of PCB circuit boards. Capel recognizes this importance and has implemented a robust traceability system to ensure transparency and accountability throughout the manufacturing process. By recording and documenting every step of production, Capel can quickly identify and resolve any issues, ensuring the reliability of the final product.

With their extensive experience, Capel utilizes various traceability tools such as barcode scanning, serial number tracking and quality logging, allowing them to track the journey of each PCB board. These measures provide valuable information about the source of the components, the manufacturing processes involved and test results, allowing Capel to troubleshoot and optimize production when needed.

2. Maintain quality assurance standards through rigorous testing:

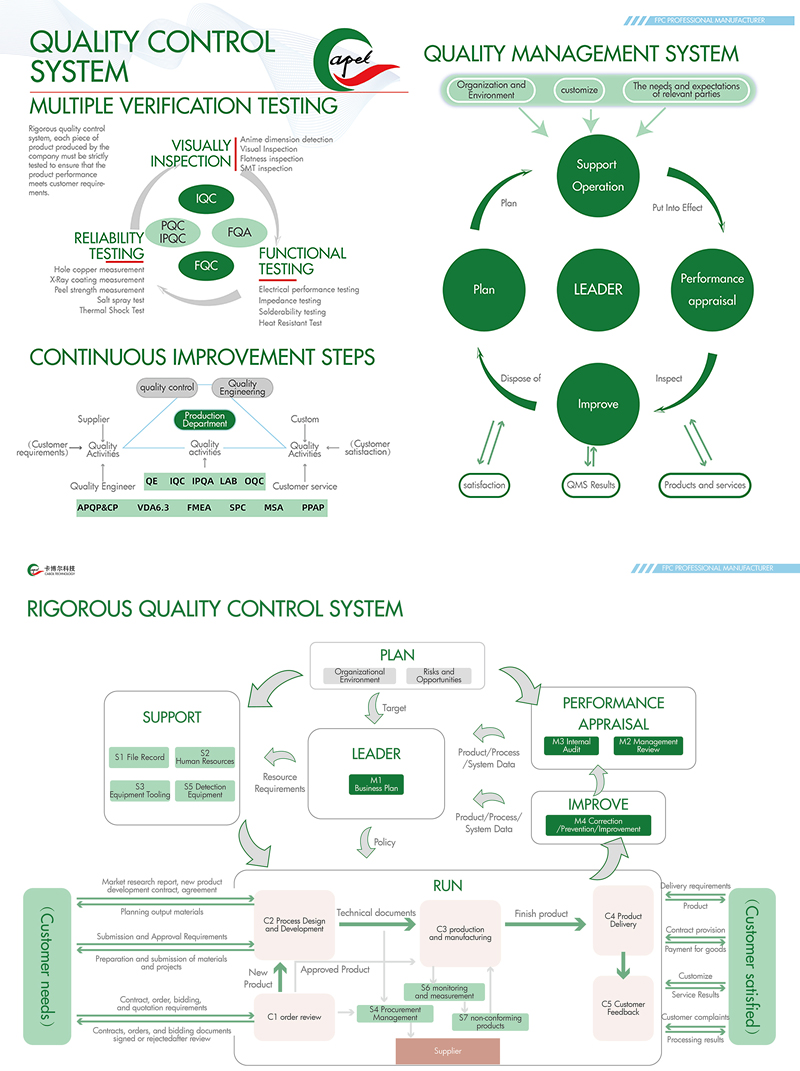

Providing high-quality PCB circuit boards requires comprehensive quality assurance practices. Capel’s commitment to quality assurance is demonstrated by their adherence to strict industry standards and meticulous testing procedures. Through rigorous testing at multiple stages throughout the manufacturing process, Capel ensures that its PCB boards meet and exceed customer expectations.

Capel has state-of-the-art testing facilities and a skilled quality assurance team, enabling them to perform a variety of testing, including bare board testing, functional testing, and environmental testing. These tests ensure that components are soldered correctly, electrical connections are secure, and the board can withstand a variety of environmental conditions.

In addition, Capel’s quality assurance process extends to working with trusted suppliers who provide reliable and certified components. Through extensive quality checks on incoming materials, Capel ensures components that meet the highest industry standards.

3. Integrate advanced technologies and manufacturing practices to enhance traceability and quality :

Capel’s years of experience enable them to continuously improve their manufacturing processes, integrate advanced technologies, and improve the traceability and quality of PCB circuit boards. Through continuous improvement initiatives, Capel remains at the forefront of technological advancement, providing customers with cutting-edge solutions.

Capel leverages Computer Aided Manufacturing (CAM), Automated Optical Inspection (AOI) and X-ray inspection technologies to deliver unprecedented accuracy and precision in the manufacturing of PCB circuit boards. These technologies not only optimize production but also aid traceability by capturing precise data at every stage of manufacturing.

In addition, Capel utilizes an ERP (enterprise resource planning) system to streamline operations and maintain detailed records of inventory, production planning and quality-related data. The integration of ERP systems with their traceability practices ensures a complete and auditable history of every PCB board.

To further enhance its traceability practices, Capel has also adopted a “smart factory” concept powered by the Internet of Things (IoT). By connecting data points across various stages of production and within the facility, Capel processes the data in real time, enabling differences to be immediately identified and manufacturing processes to be quickly adjusted.

4. Capel’s commitment to customer satisfaction :

In its 15 years in the circuit board industry, Capel’s ultimate goal has always been customer satisfaction. From timely communication and reliable order fulfillment to unparalleled traceability and quality assurance, Capel puts the needs of its customers at the forefront of its operations.

Capel’s ongoing commitment to excellence has led to long-term partnerships with customers across industries including aerospace, medical, automotive and telecommunications. Their proven track record speaks volumes for their ability to provide unparalleled traceability, quality assurance and on-time delivery for PCB circuit boards.

Conclusion :

Capel’s 15 years in the circuit board industry demonstrates their expertise in ensuring traceability and quality assurance of PCB boards. Through robust traceability systems, rigorous testing procedures, advanced technology and a commitment to customer satisfaction, Capel sets the standard for excellence in its field. Capel continuously strives to perfect its manufacturing processes and embrace technological advancements to become the first choice for customers seeking uncompromising PCB board quality.

Post time: Nov-03-2023

Back