Introduce:

In an era when electronic devices are becoming smaller, lighter, and more versatile, the demand for flexible printed circuit boards (PCBs) has reached unprecedented levels. Industries such as automotive, aerospace, and medical are increasingly adopting hybrid technology PCB circuit boards, which combine rigid and flexible components. In order to cater to this growing market, Capel is a well-known company that has been focusing on mid-to-high-end rigid-flex PCBs for 15 years in addition to flexible PCBs and HDI PCBs. In this blog, we delve into Capel’s expertise and explore the possibilities it offers in handling mixed technology PCB manufacturing.

Learn about mixed technology PCB circuit boards:

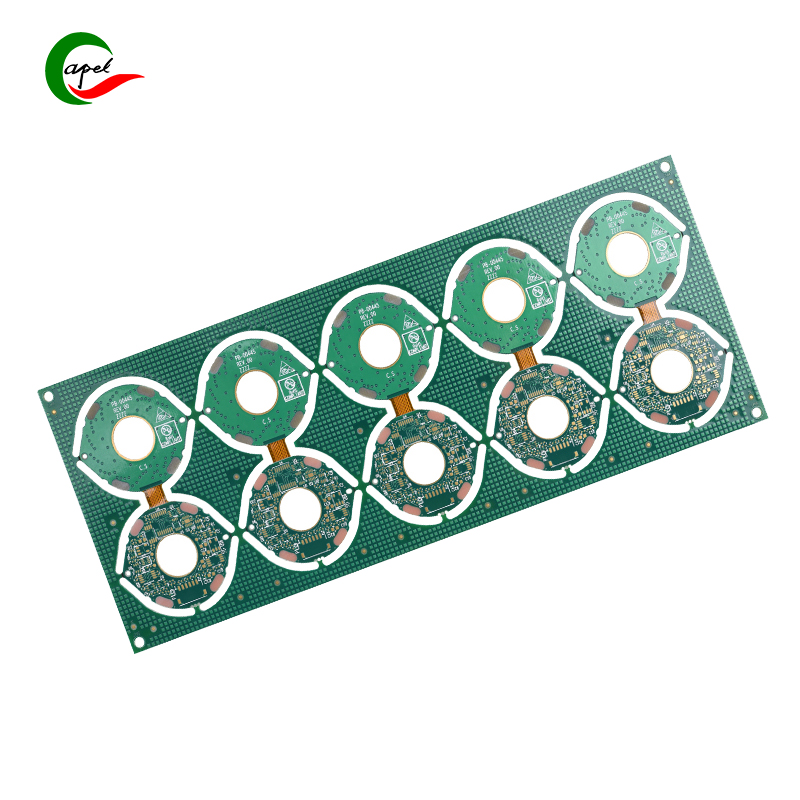

Hybrid Technology PCB Circuit boards, also known as hybrid PCBs, combine rigid substrates with flexible materials to increase design flexibility, reduce weight, and enhance reliability. Rigid sections are typically used to house components with higher power requirements, such as connectors and large ICs. Flexible parts, on the other hand, provide freedom of movement for smaller, more delicate parts, allowing for better integration into complex mechanical assemblies.

Capel’s experience and capabilities:

With 15 years of industry experience, Capel has established itself as a reliable and professional PCB circuit board manufacturer. Their core focus is on producing high-quality rigid-flex PCBs, flexible PCBs, and HDI PCBs. Over the years, the company has developed advanced manufacturing processes and purchased state-of-the-art equipment to address the challenges associated with mixed technology PCBs.

The manufacturing process of mixed technology PCB:

When manufacturing mixed technology PCBs, Capel uses rigorous processes to ensure optimal performance and reliability. They use a combination of rigid and flexible substrates and specific materials based on design requirements. Capel engineers carefully design and implement multiple layers, utilizing advanced interconnect technologies such as plated through holes and surface mount technology, to ensure a seamless connection between rigid and flexible parts.

Capel’s expertise in material selection:

One of the key aspects of mixed technology PCB manufacturing is choosing the right materials for the rigid and flexible parts. Capel excels in this area, offering a variety of flexible materials including polyimide and liquid crystal polymer (LCP). These materials offer excellent flexibility, electrical insulation, and high-temperature resistance, which are key factors in determining the reliability and longevity of mixed technology PCBs.

Quality control measures:

Capel prioritizes strict quality control measures throughout the entire manufacturing process. Advanced inspection technologies such as automated optical inspection (AOI) and X-ray inspection are used to accurately detect any potential defects or anomalies. This meticulous attention to detail ensures that every PCB leaving Capel’s factory meets the highest industry standards.

Customer-centric approach:

Capel understands that each customer has unique requirements for mixed technology PCBs. The company’s team of professional engineers and designers work closely with customers to understand their needs, provide technical guidance, and deliver turnkey solutions. Capel’s customer-centric approach enables them to provide custom mixed technology PCBs tailored to specific applications and industry requirements.

Recognition and Certification:

Capel’s expertise and commitment to excellence have earned recognition and recognition from professionals and certifications across a variety of industries. The company adheres to ISO 9001 quality management system certification to ensure its compliance with international quality and reliability standards.

In conclusion:

As the demand for mixed technology PCB boards continues to grow, Capel is at the forefront of innovation and manufacturing excellence. With extensive experience, advanced manufacturing processes, and a commitment to quality, Capel is well-equipped to meet the challenges of mixed-technology PCB manufacturing. Whether it is Rigid-Flex PCB, Flexible PCB, or HDI PCB, Capel provides unparalleled expertise and customer-oriented solutions. By partnering with Capel, customers can take advantage of the vast possibilities of mixed technology PCBs and reach new heights of success in the ever-evolving electronics industry.

Post time: Nov-04-2023

Back