Introduce:

In electronics manufacturing, PCB assembly and testing are critical steps in ensuring the smooth operation and reliability of printed circuit boards (PCBs). With 15 years of circuit board manufacturing experience, Capel is a well-known company providing comprehensive process support for PCB assembly and testing. In this blog, we’ll delve deeper into Capel’s expertise in these areas, exploring their capabilities and how they help enable a seamless PCB manufacturing process.

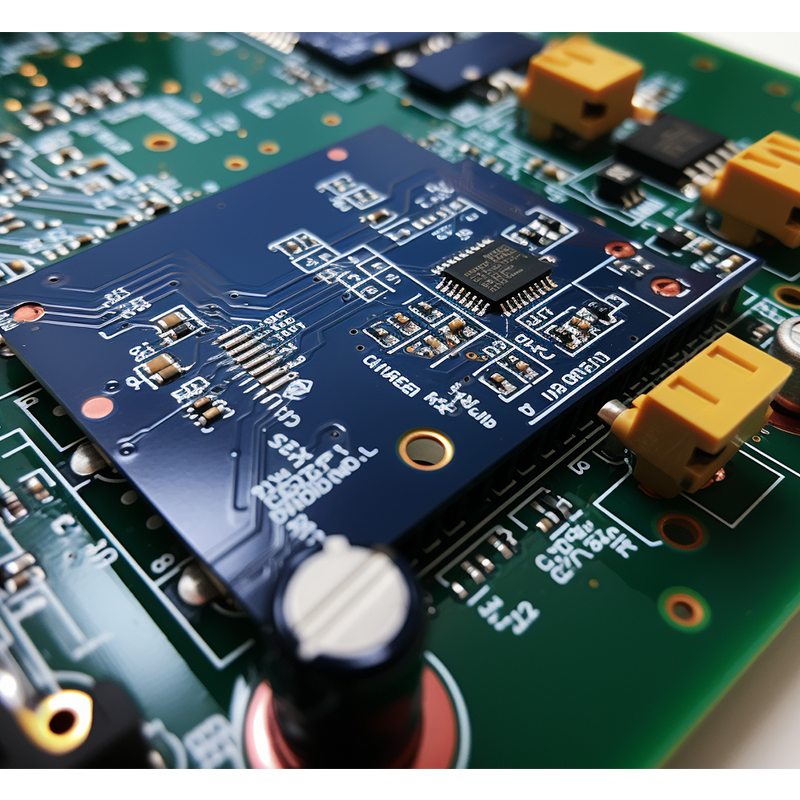

Understand the PCB assembly process:

PCB assembly is a complex process that involves combining electronic components onto a printed circuit board to create a functional device. Capel understands the complexities of this process and has the skills and equipment needed to handle it expertly. Their goal is to optimize the assembly process and deliver superior quality and seamless functionality while adhering to industry standards and best practices.

Component procurement:

One of the key aspects of PCB assembly is sourcing the right components. Capel ensures that only genuine and high quality parts are used for assembly. Their extensive supplier network allows them to source components from trusted manufacturers, reducing the risk of counterfeit or substandard parts. Effective component sourcing not only ensures reliability, but also improves the overall performance and longevity of the PCB.

Surface Mount Technology (SMT) Assembly:

Capel specializes in Surface Mount Technology (SMT) assembly, a widely used and efficient method of mounting electronic components onto PCBs. SMT offers many advantages, including higher component density, greater reliability, and lower production costs. Capel’s state-of-the-art SMT assembly capabilities combined with its skilled technicians ensure precise placement, accurate soldering and optimal joint quality, resulting in reliable and high-performance PCBs.

Through hole assembly:

While SMT is the preferred method for PCB assembly, some components and applications require through-hole assembly. Capel meets such requirements by offering through-hole assembly services. The technique involves inserting the leads of an electronic component into a drilled hole on the PCB and then soldering them on the other side. Capel’s expertise in through-hole assembly ensures the process is flawless, resulting in secure connections for even the most demanding applications.

Rigorous testing procedures:

For Capel, PCB assembly doesn’t end with component placement and soldering. They recognize the importance of thorough testing to identify any possible faults or defects. Capel’s testing procedures cover a range of methods, including functional testing, in-circuit testing (ICT) and burn-in testing. These rigorous testing procedures are designed to verify the integrity of the assembled PCB, ensuring that each component operates as expected and that the entire system meets required specifications.

Functional testing and quality assurance:

Capel’s commitment to quality extends beyond individual component testing. They conduct comprehensive functional testing to evaluate the overall performance of the assembled PCB. By simulating real-life scenarios, Capel can identify any inconsistencies or issues, facilitate timely corrections and minimize future failures. Their emphasis on quality assurance ensures that only satisfactory PCBs are delivered to customers, thereby increasing customer satisfaction and reducing the risk of late production failures.

Continuous improvement and research and development:

Capel’s experience in circuit board manufacturing fosters a culture of continuous improvement and research and development (R&D). They continually strive to enhance PCB assembly and test processes and keep up with evolving technology and industry trends. This dedication to innovation ensures that Capel remains at the forefront of the industry, providing customers with cutting-edge solutions and staying ahead of the competition.

In conclusion:

Capel’s extensive experience in circuit board manufacturing, coupled with their expertise in PCB assembly and testing processes, makes them a reliable partner for electronics manufacturers worldwide. By prioritizing component sourcing, employing advanced assembly techniques, conducting rigorous testing, and cultivating a culture of continuous improvement, Capel has set a new benchmark in PCB manufacturing. With an unwavering commitment to quality and customer satisfaction, Capel has proven to be the go-to resource for comprehensive process support related to PCB assembly and testing.

Post time: Nov-01-2023

Back