Explore Capel’s comprehensive guide to prototyping and manufacturing 4-layer flexible PCBs in consumer electronics. With 16 years of expertise, Capel’s advanced technology and professionalism in flexible PCB design, prototyping and manufacturing are demonstrated, reflecting their commitment to excellence and innovation.

1. Introduction to 4-layer flexible PCB in consumer electronics

In the rapidly growing consumer electronics sector, there is a growing demand for innovative and high-performance flexible printed circuit boards (PCBs). As an industry leader, Capel has become a trusted partner in consumer electronics flexible PCB design, prototyping and manufacturing. With 16 years of experience, Capel has demonstrated its expertise in providing best-in-class solutions for 4-layer flexible PCBs that meet the specific needs of the consumer electronics industry.

2. Main specifications and features of Capel 4-layer flexible PCB

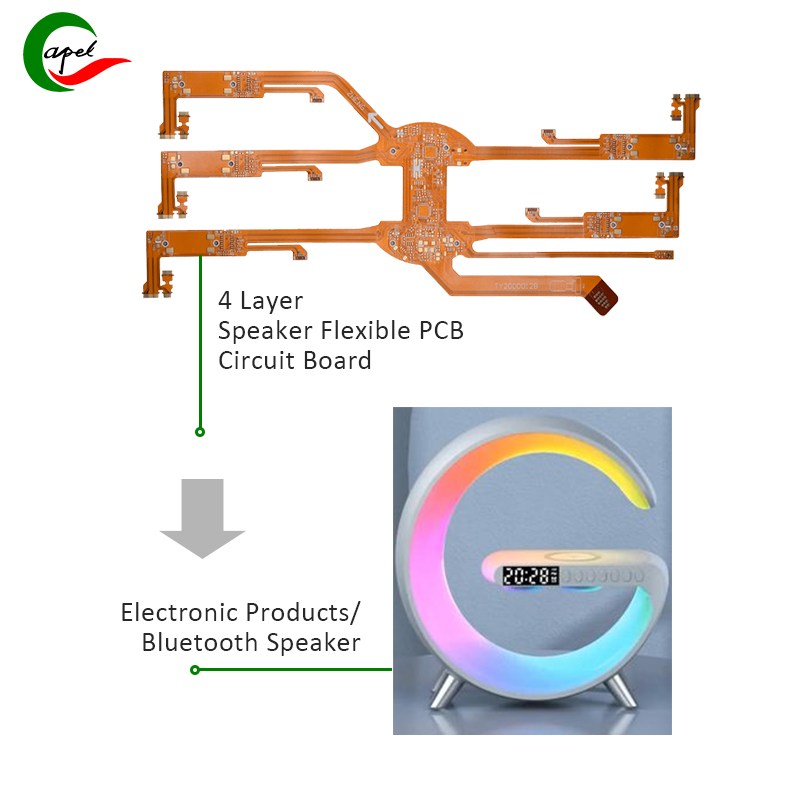

Consumer electronics often require compact, lightweight PCB solutions that can accommodate complex circuitry while providing flexibility and durability. The 4-layer flexible PCBs offered by Capel are designed to meet these requirements, making them ideal for a wide range of applications in the consumer electronics industry.

3. Case study: Capel’s expertise in consumer electronics 4 layer flexible PCBs

Capel’s 4-layer flex PCB is constructed of 3 layers of FPC and 1 layer of double-sided FPC, providing a unique combination of flexibility and ruggedness. With a minimum line spacing of 0.1 mm and a minimum drill hole size of 0.2 mm, these PCBs can accommodate complex designs and densely packed components. The 0.55mm slot size further enhances the versatility of these PCBs, allowing for the integration of a variety of connectors and components.

The unit size of 372*153mm provides ample space for designing complex circuit layouts, while the yellow overlay and white silk screen contribute to the aesthetics of the PCB. The ENIG 2U surface treatment ensures excellent electrical conductivity and corrosion resistance, making the PCB suitable for long-term use in consumer electronics equipment.

In addition, 27 PI ribs and 1 SUS rib enhance the mechanical strength and stability of the PCB, allowing it to withstand the rigors of practical applications.

Case Study: Capel’s Expertise in Flexible PCBs for Consumer Electronics

Capel’s extensive experience in consumer electronics flexible PCB design, prototyping and manufacturing was demonstrated in a recent project to develop a 4-layer flexible PCB for a leading consumer electronics manufacturer. Customers needed a high-performance PCB solution to meet the stringent requirements of their next-generation electronic devices.

Capel’s team of engineers and designers work closely with customers to understand their specific needs and challenges. With in-depth knowledge of flexible PCB materials and manufacturing processes, Capel proposes customized solutions based on a 4-layer flexible PCB structure, tailored to the customer’s application needs.

Through careful design and prototyping, Capel demonstrated the feasibility and performance of a 4-layer flexible PCB, ensuring it met customer expectations in terms of electrical performance, mechanical flexibility and overall reliability. The successful completion of the prototype phase paves the way for a seamless transition to mass production, with Capel’s advanced manufacturing capabilities ensuring consistent quality and timely delivery of PCBs.

4. Advantages of Capel consumer electronics 4 layer flexible PCB solutions

Capel’s expertise in consumer electronics flexible PCB design, prototyping and manufacturing provides companies in the consumer electronics industry with several key advantages:

1. Customized Solutions: Capel’s in-depth understanding of flexible PCB materials and construction techniques enables the development of custom solutions that meet the specific needs of consumer electronics applications.

2. Advanced technology: Capel focuses on innovation and technological advancement, utilizing the most advanced manufacturing processes and equipment to provide high-quality 4-layer flexible PCBs that meet the highest industry standards.

3. Professionalism and professionalism: Capel’s 16 years of accumulated project experience reflects the company’s commitment to professionalism, professionalism and continuous improvement in the field of consumer electronics flexible PCBs.

4. Excellent process capabilities: Capel’s strong process capabilities ensure seamless execution of flexible PCB design, prototyping and manufacturing, resulting in reliable, high-performance PCB solutions.

4 Layer Flexible PCB Manufacturing Process for Consumer Electronics

5. Conclusion: Capel – Promoting the advancement of consumer electronics flexible PCBs

In summary, Capel’s 4-layer flexible PCBs represent the pinnacle of engineering excellence and innovation in consumer electronics. With a proven track record of successful project collaborations and a strong commitment to quality and customer satisfaction, Capel is a reliable partner for businesses seeking cutting-edge solutions in consumer electronics flexible PCB design, prototyping and manufacturing. As the consumer electronics industry continues to evolve, Capel remains at the forefront, driving progress and delivering superior PCB solutions to power the next generation of electronic devices.

Post time: Mar-11-2024

Back