In today’s fast-paced technology environment, flexibility and efficiency have become critical in the design and production of electronic devices. Printed circuit boards (PCBs) play a vital role in providing the necessary electrical connections for these devices. When it comes to flexible PCB, the two terms that often appear are HDI flexible PCB and regular FPCB. While both serve similar purposes, there are significant differences between them. This blog aims to shed light on these differences and provide a comprehensive understanding of HDI Flex PCBs and how they differ from regular FPCBs.

Learn about flexible PCBs:

Flexible PCBs, also known as FPCBs or flexible circuits, have revolutionized the electronics industry by improving space utilization and design freedom. Unlike rigid PCBs, which are made from rigid materials like FR4, flex PCBs are built using flexible substrates like polyimide. This flexibility allows FPCBs to be bent, twisted or folded to fit tight spaces or unusual shapes. Its complex structure makes it the first choice for a variety of applications, including smartphones, wearables, medical devices, and automotive electronics.

Explore HDI flex PCB:

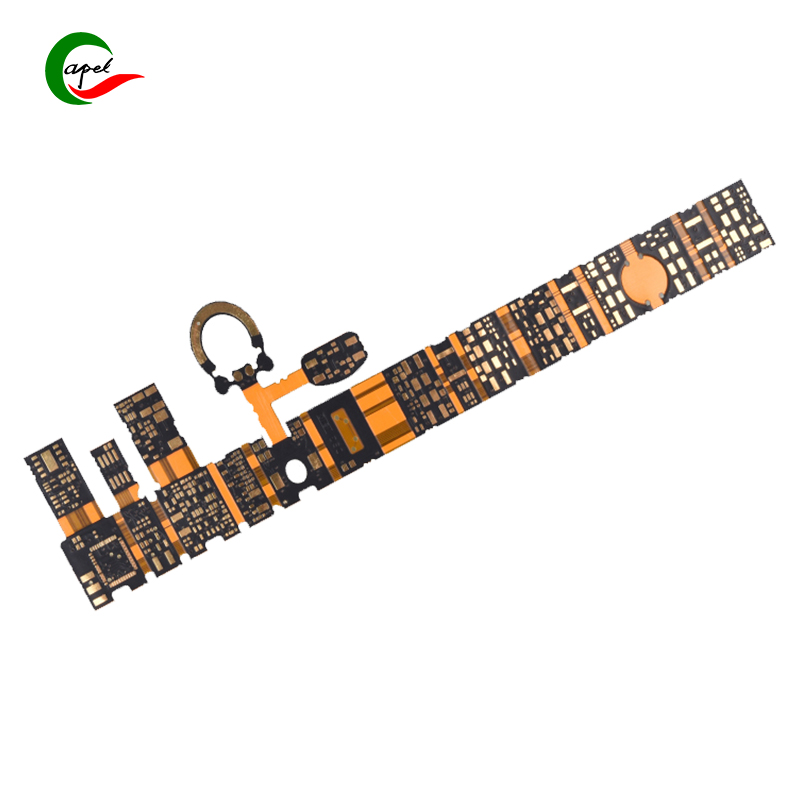

HDI, short for High Density Interconnect, describes a manufacturing technique that increases the density and performance of circuit boards. HDI Flex PCB combines the advantages of HDI and flex circuit technologies, resulting in a highly compact and flexible solution. These specialized PCBs are created by combining multiple layers of flexible materials with advanced HDI features such as microvias, blind and buried vias, and fine-line trace/space geometries.

The difference between HDI flexible PCB and ordinary FPCB:

1. Number of layers and density:

Compared with regular FPCB, HDI Flex PCB usually has more layers. They can accommodate multiple complex circuit layers in a compact form factor, providing higher density interconnects and greater design flexibility. The increase in the number of layers allows for the integration of additional components and functions.

2. Advanced interconnection technology:

As mentioned earlier, HDI Flex PCBs utilize advanced interconnect technologies such as microvias, blind and buried vias, and fine-line trace/space geometries. These technologies enable high-speed data transmission, reduce signal loss, and improve signal integrity. Conventional FPCBs, although flexible, may not have such advanced interconnection technology.

3. Design flexibility:

While regular FPCBs have excellent flexibility, HDI Flex PCB goes one step further. Increased layer counts and advanced interconnect technologies provide design engineers with unparalleled routing flexibility, enabling complex and compact designs. This versatility is especially useful when developing tiny electronics or products where space is limited.

4. Electrical performance:

HDI flexible PCB is superior to ordinary FPCB in terms of electrical performance. Microvias and other advanced features in the HDI Flex PCB help reduce insertion loss and crosstalk, ensuring stable signal integrity even in high frequency applications. This enhanced electrical performance makes HDI Flex PCBs the first choice for devices that require optimal signal transmission and reliability.

In Conclusion:

HDI Flex PCB is different from conventional FPCB in terms of layer count, density, advanced interconnect technology, design flexibility and electrical performance. HDI flex PCBs offer unique advantages for complex and space-constrained electronic assemblies where high-density interconnects and signal integrity are critical. Understanding the differences between these technologies can help designers choose the most suitable PCB solution for their specific application.

As technology continues to advance, the need for smaller and more powerful electronic devices will only increase. HDI flex PCBs represent cutting-edge technology in flexible circuits, pushing the limits of miniaturization and performance. With its superior design flexibility and electrical functionality, HDI Flex PCB is poised to drive innovation and revolutionize the electronics industry.

Post time: Sep-02-2023

Back