Introduce:

In today’s technology-driven world, the demand for complex and flexible printed circuit boards (PCBs) is growing rapidly. From high-performance computing systems to wearables and medical devices, these advanced PCBs have become an integral part of modern electronics. However, as complexity and flexibility requirements increase, so does the need for cutting-edge production technologies that can meet these unique needs. In this blog, we will explore the evolving landscape of PCB production and discuss whether it is capable of meeting the requirements of complex and flexible PCBs.

Learn about complex and flexible PCBs:

Complex PCBs are characterized by complex designs that integrate multiple functions within a limited space. These include multilayer PCBs, high-density interconnect (HDI) boards, and PCBs with blind and buried vias. Flexible PCBs, on the other hand, are designed to be bent or twisted without damaging the circuitry, making them ideal for applications where flexibility and space optimization are crucial. These PCBs typically use flexible substrates such as polyimide or polyester.

The rise of advanced production technology:

Traditional PCB production methods, such as etching, lamination, etc., are not enough to meet the needs of complex, flexible PCBs. This has led to the development of a variety of advanced production technologies that provide greater precision, flexibility and efficiency.

1. Laser Direct Imaging (LDI): LDI technology uses lasers to directly expose PCB substrates, eliminating the need for time-consuming and error-prone photomasks. The technology enables the production of ultra-fine circuits, thinner traces and smaller vias, which are critical for complex PCBs.

2. Additive Manufacturing: Additive manufacturing or 3D printing has revolutionized the production of complex and flexible PCBs. It makes it easy to create complex designs, especially for prototypes and low-volume production. Additive manufacturing enables rapid iteration and customization, helping designers and manufacturers meet the unique needs of complex and flexible PCBs.

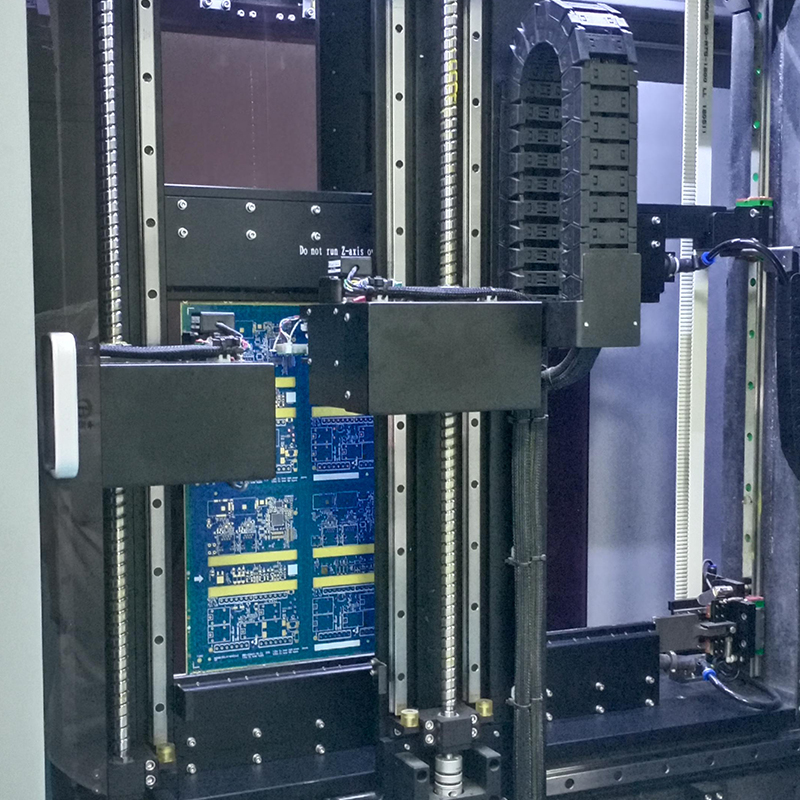

3. Flexible substrate handling: Traditionally, rigid PCBs were the norm, limiting design possibilities and reducing the flexibility of electronic systems. However, advances in substrate materials and processing technology have opened up new avenues for the production of flexible printed circuit boards. Manufacturers are now equipped with specialized machinery that ensures the correct handling and alignment of flexible substrates, minimizing the risk of damage during production.

Challenges and solutions:

Although advanced production technology continues to advance, challenges still need to be overcome to fully meet the production needs of complex, flexible PCBs.

1. Cost: Implementing advanced production technologies usually requires higher costs. This can be attributed to the initial investment required in equipment, training and specialist materials. However, as these technologies become more widespread and demand increases, economies of scale are expected to reduce costs.

2. Skills and training: Adopting new production technologies requires technicians skilled in operating and maintaining advanced machinery. Companies need to invest in ongoing training programs and attract talent to ensure a smooth transition to these innovative technologies.

3. Standards and quality control: As PCB technology continues to develop, it has become crucial to establish industry standards and implement strict quality control measures. Manufacturers, regulators and industry associations need to work together to ensure the reliability and safety of complex and flexible PCBs.

In summary:

Driven by the growing demands of modern electronic systems, the production needs of complex and flexible PCBs are constantly changing. While advanced production technologies such as laser direct imaging and additive manufacturing have significantly improved PCB manufacturing capabilities, there are still challenges to overcome in terms of cost, skills and quality control. However, with continued efforts and collaborative initiatives, the production landscape is poised to meet and exceed the needs of complex and flexible PCBs. As technology continues to advance, we can expect continued innovation in production processes to ensure seamless integration of PCBs into the most cutting-edge electronic applications.

Post time: Oct-30-2023

Back