Introduction: The role of rigid-flex laminates in the automotive industry

As an experienced circuit board engineer in the automotive industry, it is critical to stay up to date with the latest technological advancements. One advancement making waves in the automotive industry is the use of rigid-flex PCBs. These innovative circuit boards play a vital role in the operation of modern automotive systems, and it is important for engineers to understand their importance.

Rigid-flexible PCB design flexibility and size advantages

At Capel, we have over 15 years of experience in the circuit board industry and we understand the importance of staying ahead of the curve when it comes to new technologies. In this blog, we’ll explore the role of rigid-flex PCBs in automotive systems and what you need to know about them.

Mechanical elasticity: reduces vibration and mechanical stress

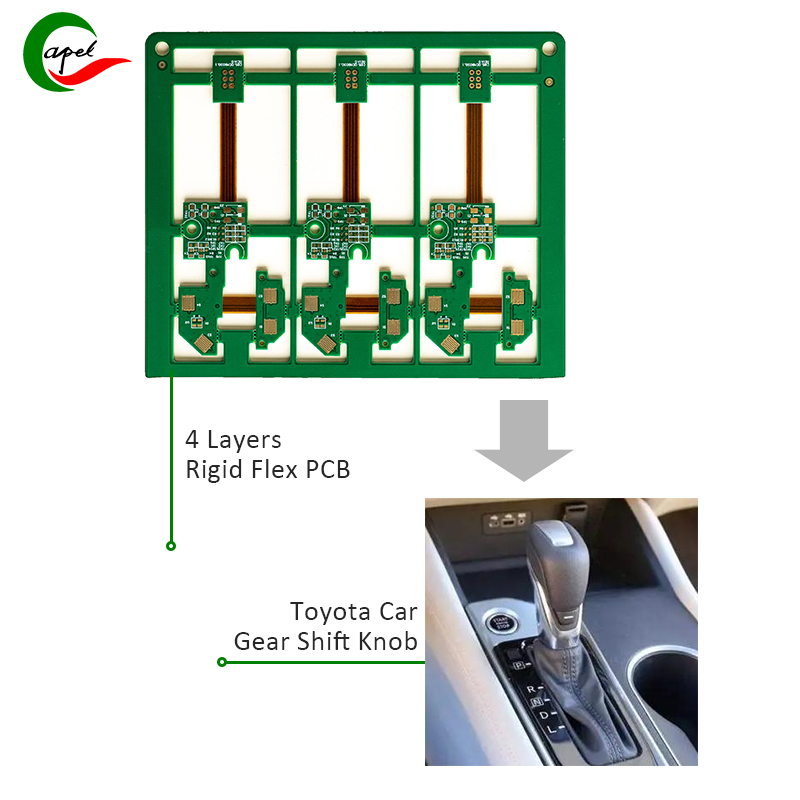

Rigid-flex board is a circuit board that combines rigid and flexible board materials. This unique structure allows for greater design flexibility and the ability to create more compact, lighter electronic devices. In automotive systems where space is often at a premium, rigid-flex PCBs offer many advantages over traditional rigid boards.

Enhanced features: Efficient connection routing and performance

One of the main advantages of rigid-flex boards in automotive systems is their ability to withstand high levels of vibration and mechanical stress. This is particularly important for applications where reliability is critical, such as airbag control systems. The flexible portions of the circuit board help absorb and disperse the forces exerted on the circuit board, thereby reducing the risk of mechanical failure.

Weight reduction and environmental impact of rigid-flex boards

In addition, the flexibility of rigid-flexible PCBs makes connection wiring within the system more efficient. This shortens the signal path, reduces electromagnetic interference, and improves overall system performance. These advantages are important in automotive applications where reliability and performance are critical.

Another important aspect of rigid-flex PCBs in automotive systems is their ability to reduce overall system weight. Today’s automotive industry places great emphasis on improving fuel efficiency and reducing emissions. By using lightweight materials, such as rigid-flex PCBs, automotive engineers can help achieve these goals without compromising performance or safety.

Design flexibility and optimization in automotive applications

In addition to these advantages, rigid-flex PCBs offer greater design flexibility, which is especially important in automotive applications. With the ability to create more complex and compact designs, engineers can optimize interior space and improve the overall functionality of electronic systems.

Ensure the quality and reliability of rigid-flex board manufacturing

When using rigid-flex PCBs in automotive systems, it is important to ensure that the boards are manufactured to the highest standards. This includes using high-quality materials, adhering to strict design and manufacturing processes, and conducting thorough testing and validation procedures.

At Capel, we understand the critical role rigid-flex PCBs play in automotive systems, and we are committed to providing our customers with the highest quality products. With our extensive experience in the circuit board industry, we have the expertise to provide customized solutions that meet the unique requirements of automotive applications.

Conclusion: Using rigid-flexible PCB to advance automotive technology

In summary, the role of rigid-flex boards in automotive systems is very important, and engineers in the automotive industry must understand the advantages and importance of these innovative circuit boards. From the ability to withstand high levels of vibration and mechanical stress to the impact on system weight and performance, rigid-flex PCBs are helping to advance automotive technology.

As a circuit board engineer in the automotive industry, it is important to stay up to date with the latest technologies and trends. By understanding the importance of rigid-flex PCBs, engineers can help push the limits of automotive system design and functionality. With the right expertise and a commitment to quality, engineers can leverage rigid-flex PCBs to create innovative and reliable automotive systems for the future.

Post time: Dec-15-2023

Back