Flex PCB Assembly Revolutionizes The Internet of Things (IOT):

In today’s technologically advanced world, connectivity is key to unlocking the true potential of the Internet of Things (IoT). As more and more devices are connected to each other, reliable and efficient communication is critical. This is where flex PCB assembly comes into play, revolutionizing how we connect and communicate in the age of the Internet of Things.

Flexible PCB Assembly Technology:

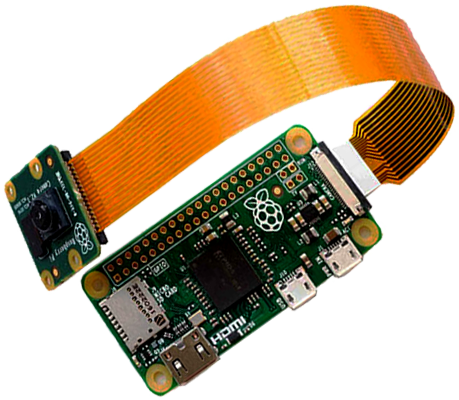

Flexible printed circuit board assembly, also known as flexible printed circuit board assembly, is a technology that allows electronic circuits to be created on flexible substrates. Unlike traditional rigid PCBs, flexible PCBs offer a wide range of advantages that make them ideal for IoT applications.

Flexible Circuit Assembly Accommodates Complex and Irregular Shapes:

One of the main advantages of flexible PCB assembly is the ability to accommodate complex and irregular shapes. This flexibility opens up a whole new world of design possibilities, allowing the creation of innovative and compact IoT devices. Whether it’s a wearable fitness tracker, smart home sensor, or medical device, a flex PCB can be customized to meet the specific needs of any application.

Flexible Printed Circuit Board Assembly’s Durability:

Another important feature of a flexible printed circuit board assembly is its durability. As IoT devices become more prevalent in our daily lives, they are affected by various environmental factors such as temperature fluctuations, humidity and vibrations. Traditional rigid PCBs may not be able to withstand these conditions, resulting in device failure or failure. In contrast, flex PCBs are designed to withstand harsh environments, ensuring reliable performance even under extreme conditions. This durability makes flex PCB assemblies ideal for IoT applications where devices are often installed in demanding environments such as industrial environments or outdoor installations.

Flex PCB Assembly’s Signal Integrity:

In addition, flex PCBs have excellent signal integrity. The ability to bend and twist without affecting the electrical connection ensures reliable data transfer between various IoT devices. This enhances the overall performance of the interconnected network and reduces the risk of data loss or transmission errors.

The combination of flexibility, durability, and signal integrity makes flex PCBs an ideal solution for the fast-growing IoT market. With the number of IoT devices expected to reach billions in the next few years, it is critical to have a reliable and efficient method of connectivity. Flexible PCB assembly just meets this need.

Flexible PCB Assembly’s Manufacturing Process Offers Cost-Saving Benefits:

Additionally, the manufacturing process for flex PCB assembly offers cost-saving benefits to IoT product developers. As technology advances, the production of flexible PCBs has become more streamlined and efficient. The ability to print circuits onto flexible substrates reduces material waste and lowers production costs. Additionally, the integration of multiple components onto a single flexible PCB requires no additional interconnects, simplifying the assembly process and reducing overall manufacturing costs. These cost-saving advantages make flex PCB assembly the first choice for IoT manufacturers to optimize the production process while maintaining high-quality standards.

Flexible PCB Assembly Connectivity:

In the world of IoT, connectivity is everything. Flexible PCB assembly plays a vital role in ensuring seamless and reliable connections between various devices. The flexibility of these PCBs allows for complex electrical signal routing, enabling efficient communication between components. Whether transmitting data from a wearable device to a smartphone or connecting sensors in a smart home setup, flexible PCBs act as a bridge that facilitates uninterrupted communication in the IoT ecosystem.

Flexible PCB Assembly High-Density Component Placement:

For optimal performance and connectivity, IoT devices often require space-efficient solutions. Flexible PCB assembly meets this requirement by enabling high-density component placement. The ability to pack more components onto a smaller PCB space enables the miniaturization of IoT devices without compromising functionality. This compactness is especially important in IoT applications where size limitations are a constraint.

Shenzhen Capel Technology Co., Ltd. was established in 2009 and its’ circuit boards Assembling capacity of 150,000,000 components per month now.

In conclusion, flex PCB assembly is redefining connectivity in the IoT era. Its ability to adapt to different form factors, durability in challenging environments, cost-saving advantages, and role in enabling seamless connectivity make it an indispensable technology for IoT manufacturers. As the demands of IoT devices continue to grow, the importance of flex PCB assembly will only increase. Adoption of this technology is critical to staying ahead in the rapidly evolving IoT world and unlocking the full potential of connectivity in the IoT era.

Post time: Aug-22-2023

Back