In this article, we’ll take a closer look at the materials commonly used in flexible printed circuit manufacturing.

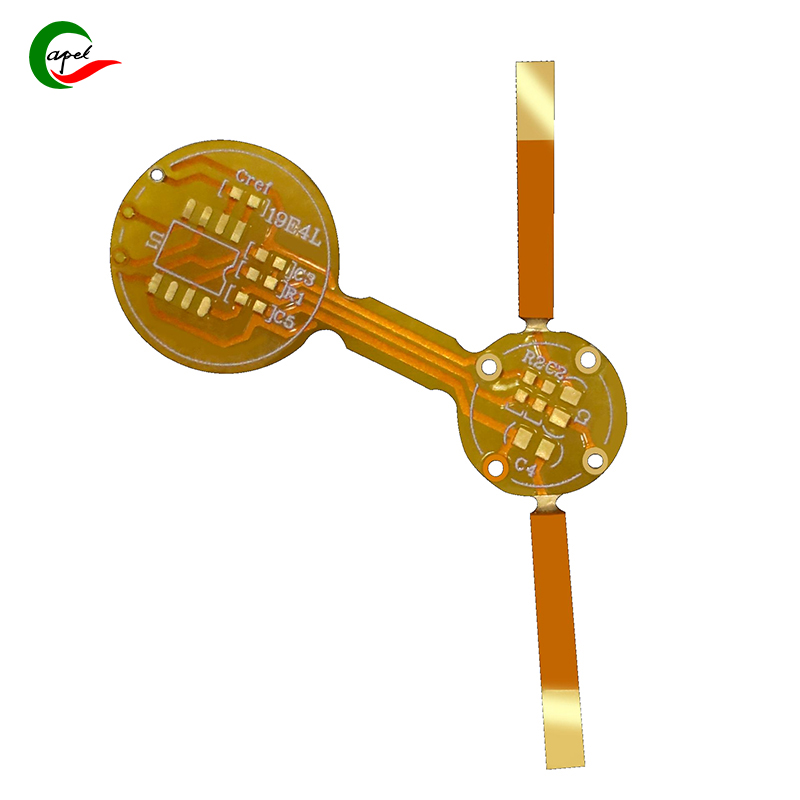

Flexible printed circuits (FPC) have dramatically changed the field of electronics. Their ability to bend makes them popular in various industries including aerospace, automotive, healthcare, and consumer electronics.

One of the main materials used in the production of flexible printed circuits is polyimide. Polyimide is a high-performance polymer with excellent thermal stability, chemical resistance and mechanical toughness. These properties make it ideal for flexible circuits as it can withstand high temperatures and harsh environments without affecting its functionality. Polyimide-based films are commonly used as substrates for flexible printed circuits.

In addition to polyimide, another material often used in flexible printed circuit manufacturing is copper. Copper was chosen for its excellent electrical conductivity, corrosion resistance and ductility. Thin copper foil is typically laminated to a polyimide substrate to form the conductive path for the circuit. The copper layer provides the necessary electrical interconnections required for the circuit to function properly.

To protect the copper traces and ensure the longevity of the flexible printed circuit, a cover layer or solder mask is required. Overlay is a thermoset adhesive film typically applied to circuit surfaces. It acts as a protective layer, protecting the copper traces from environmental factors such as moisture, dust, and physical damage. The cover material is usually a polyimide-based film, which has high bonding strength and can be firmly bonded to the polyimide substrate.

To further enhance the durability and functionality of flexible printed circuits, reinforcing materials such as tape or reinforcing materials are often used. Add reinforcements to specific areas of a circuit where extra strength or stiffness is needed. These materials can include a variety of options, such as polyimide or polyester film, fiberglass, or even metal foil. Reinforcement helps prevent circuits from tearing or breaking during movement or operation.

In addition, pads or contacts are added to facilitate the connection between the flexible printed circuit and other electronic components. These pads are typically made from a combination of copper and solder-resistant materials. Bonding pads provide the necessary interface for soldering or connecting components such as integrated circuits (ICs), resistors, capacitors, and connectors.

In addition to the above core materials, other substances can also be added during the manufacturing process depending on specific requirements. For example, adhesives can be used to bond different layers of flexible printed circuits together. These adhesives ensure a strong and reliable bond, allowing the circuit to maintain its structural integrity. Silicone adhesives are often used due to their flexibility, high temperature resistance, and excellent bonding properties.

Overall, the materials used in the production of flexible printed circuits are carefully selected to ensure optimal performance and durability. The combination of polyimide as a substrate, copper for conductivity, overlays for protection, reinforcement materials for added strength, and pads for component connections creates a reliable and fully functional flexible printed circuit. The ability of these circuits to adapt to a variety of applications, including curved surfaces and tight spaces, makes them indispensable in modern electronic devices.

In summary, flexible printed circuit materials such as polyimide, copper, overlays, reinforcements, adhesives, and pads are key components in creating durable and flexible electronic circuits. These materials work together to provide the necessary electrical connections, protection and mechanical strength required in today’s electronic devices. As technology continues to evolve, the materials used in flexible printed circuit manufacturing are likely to evolve further, enabling more innovative applications.

Post time: Sep-21-2023

Back