Introduce:

In the fast-paced technological world, portable electronics have become an integral part of our daily lives. From smartphones to wearables and medical devices, demand for smaller, lighter, and more advanced devices continues to grow. To meet these changing needs, the adoption of innovative circuit board technologies is critical. One technology making waves in the industry is the development and implementation of rigid-flex PCBs. In this blog, we explore how Capel leverages its 15 years of experience in circuit board manufacturing technology to revolutionize portable electronics through rigid-flex PCBs.

1. Understand the combination of rigid and flexible PCB:

Rigid-flex PCBs combine the functionality of rigid boards with the flexibility of flexible circuits, allowing for greater design freedom and more compact electronics. Traditional rigid boards are connected together with cables or connectors, often resulting in increased size, weight and potential reliability issues. Rigid-flex PCBs eliminate these limitations through seamless integration of rigid and flexible components. The technology enables the creation of highly compact and rugged electronic devices, allowing engineers and designers to realize revolutionary concepts that were previously unfeasible.

2. Advantages of rigid-flexible PCB for portable electronic products:

2.1 Miniaturization: Using rigid-flex PCB, designers can freely create complex circuits in smaller form factors. The elimination of connectors and cables reduces the overall size, weight and thickness of electronic devices, making them more portable. This is great for smartwatches, medical implants, and other wearable technology where size and comfort play a crucial role.

2.2 Enhanced reliability: Seamless integration of rigid and flexible components minimizes the number of interconnections and reduces the risk of failure. Unlike traditional circuit assemblies, which are susceptible to physical stress or vibration damage from too many connectors, rigid-flex boards offer greater mechanical stability, impact and impact resistance, and extended service life. These properties make rigid-flex boards ideal for smartphones, tablets, and other handheld electronic devices that require frequent handling and transportation.

2.3 Improve design flexibility: Rigid-flexible PCB provides unprecedented design possibilities. Their flexibility allows for complex three-dimensional configurations, allowing engineers to design products that fit into unconventional shapes or take advantage of available space within electronic devices. This enhanced freedom is valuable for integrating sensors, microcontrollers and various components in medical devices and aerospace applications.

3. Capel’s expertise in rigid-flex PCB manufacturing:

Capel has 15 years of experience in circuit board manufacturing technology, which gives them a unique advantage in rigid-flex board production. The company’s commitment to quality, advanced manufacturing processes and strict quality control measures ensure that its rigid-flex PCBs meet the highest industry standards. Capel’s team of skilled engineers and designers work closely with customers to understand their specific requirements and provide tailor-made solutions, resulting in highly reliable and cost-effective products.

4. Application of rigid-flex board:

4.1 Smartphones and Tablets: Rigid-flex PCBs enable ultra-thin smartphones and tablets, providing more space for larger batteries, add-ons, and enhanced functionality without compromising structural integrity. Additionally, flexible components provide better shock absorption, making these devices more durable.

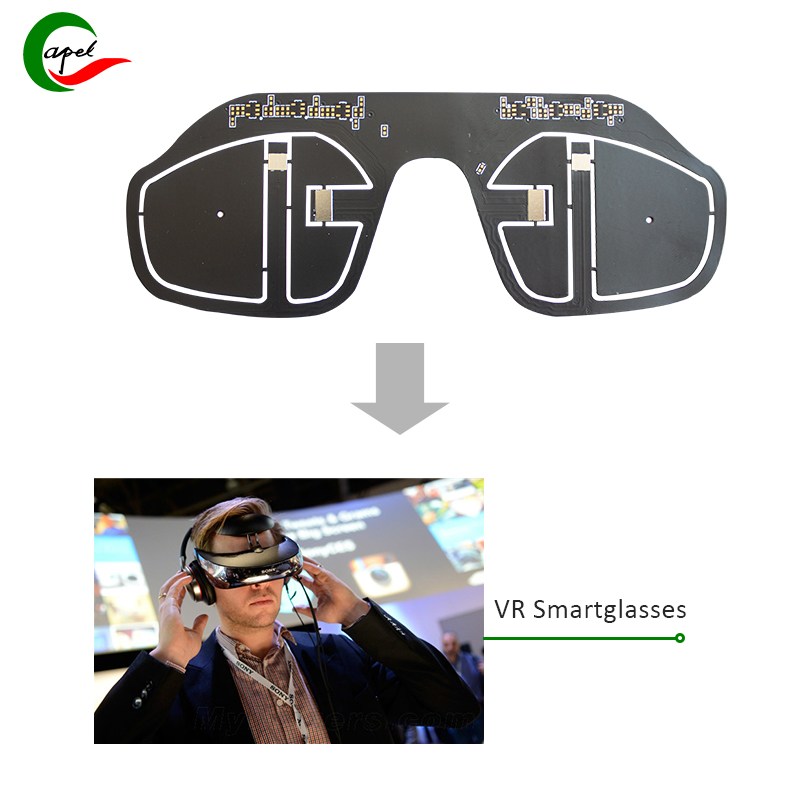

4.2 Wearable Technology: Smartwatches, fitness trackers, and other wearable devices often require a combination of rigid and flexible circuits. Rigid-flex PCBs provide the compactness, flexibility and durability these portable devices require. They integrate seamlessly into the form factor and provide the reliability required for continuous use.

4.3 Medical Devices: From pacemakers and hearing aids to medical implants and diagnostic equipment, rigid-flex boards are revolutionizing the medical industry. Their flexibility allows them to fit more closely to the body, ensuring patient comfort while meeting the required functionality. Additionally, they enable miniaturization, reducing the invasiveness of medical procedures and the overall size of the device.

4.4 Aerospace and automotive applications: Rigid-flex boards are also used in the aerospace and automotive industries. Their small size and light weight make them suitable for use in environments where space is limited. Additionally, their resistance to extreme temperatures, vibration and shock ensures the reliability and performance required of critical systems.

In conclusion:

The emergence of rigid-flexible PCBs paves the way for a new era of portable electronics. Capel’s 15 years of experience in circuit board manufacturing technology has made it a leading provider of cutting-edge rigid-flex PCB solutions. Rigid-flex PCBs have the ability to revolutionize industries such as smartphones, wearables, medical, aerospace and automotive, and their integration in portable electronics will create a future where innovation, reliability and compactness go hand in hand seamlessly.

Post time: Nov-06-2023

Back