When it comes to flexible PCBs (printed circuit boards), one of the key factors to consider is the thickness of the copper. Copper plays a vital role in the functionality and durability of flexible PCBs and is therefore an important aspect to understand. In this blog post, we’ll delve deeper into the topic of copper thickness in flexible PCBs, and Shenzhen Capel Technology Co., Ltd. supports copper thinness, discussing its importance and how it affects the overall performance of the board.

The importance of copper thickness in flexible PCB

Copper is the first choice for PCBs due to its excellent electrical conductivity and corrosion resistance. In flexible PCBs, copper is used as the conductive material that allows electrical current to flow through the circuit. The thickness of copper directly affects the performance and functionality of the flexible PCB. Here’s why copper thickness matters:

1. Current Carrying Capacity: The thickness of the copper determines how much current the PCB can safely carry without overheating or causing electrical problems. Thicker copper layers can effectively handle higher currents, ensuring smooth operation of the flex circuit.

2. Signal integrity: Flexible PCBs are often used in applications that require high signal integrity, such as aerospace, medical equipment, and telecommunications. Copper thickness affects the impedance of the trace, ensuring that signals propagate correctly with minimal loss or distortion.

3. Mechanical Strength: Flexible printed circuit boards are designed to be flexible, which means they are exposed to constant bending, twisting and flexing. The copper layer provides mechanical strength to the circuit and prevents cracks or breaks in the conductive paths. Adequate copper thickness ensures that the PCB remains strong and durable throughout its lifetime.

Learn about copper thickness measurement

In the flexible PCB world, copper thickness is typically measured in ounces per square foot (oz/ft²) or micrometers (μm). The most common copper thickness options for flexible PCBs are 0.5 oz (17.5 µm), 1 oz (35 µm), 2 oz (70 µm), and 3 oz (105 µm). The choice of copper thickness depends on specific application requirements such as current carrying capacity and mechanical strength.

Factors affecting copper thickness selection

Several factors influence the choice of copper thickness in a flexible PCB, including:

1. Current requirements: Higher current applications typically require thicker copper layers to ensure effective current carrying capabilities. Consideration must be given to the maximum current the circuit will encounter to avoid overheating of the copper or excessive voltage drop.

2. Space constraints: Smaller, more compact devices may require thinner copper layers to fit into the limited available space. However, this decision should be carefully weighed against current carrying capacity and mechanical strength requirements.

3. Flexibility: The flexibility of PCB is affected by copper thickness. Thicker copper layers are typically harder, reducing the overall flexibility of the circuit. For highly flexible applications, lower copper thicknesses are preferred.

Manufacturing precautions

Flexible PCB manufacturing processes are designed to accommodate a wide range of copper thicknesses. However, certain copper thicknesses may require additional precautions or specialized techniques during the manufacturing process. Thicker copper layers may require longer etching times to achieve the desired circuit pattern, while thinner copper layers require more delicate processing to avoid damage during assembly.

Working closely with the PCB manufacturer is critical to understand any limitations or considerations specific to the required copper thickness. This ensures a successful manufacturing process without affecting PCB performance.

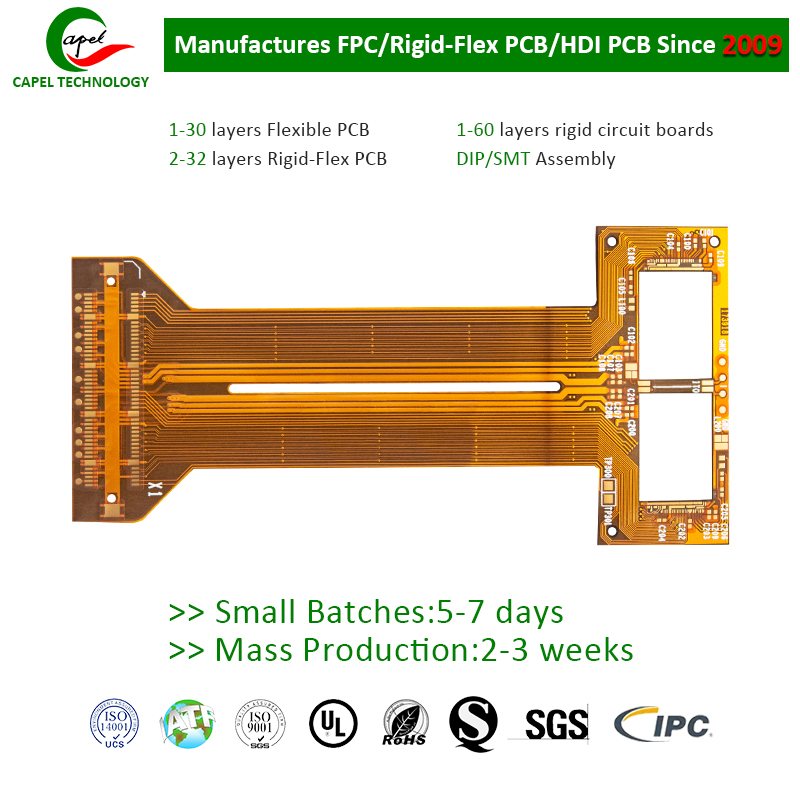

Shenzhen Capel Technology Co., Ltd. supports copper thinness in flexible pcb

Capel is a well-known company that specializes in the production of flexible printed circuit boards and understands the importance of copper thickness to the overall functionality and performance of flexible printed circuit boards. They offer a wide range of options to suit different requirements and specifications.

Standard flexible circuit:

For standard flex circuits, Capel offers a variety of copper thickness options. These include 9um, 12um, 18um, 35um, 70um, 100um and 140um. The availability of multiple options allows customers to select the appropriate copper thickness for their specific needs. Whether you need a thinner copper layer for more flexible applications or a thicker copper layer for enhanced durability, Capel has what you need.

Flat flexible circuit:

Capel also offers flat flex circuits with varying copper thicknesses. Copper thickness for these circuits ranges from 0.028mm to 0.1mm. These thin, flexible circuits are often used in space-constrained applications where traditional rigid PCBs cannot be used. The ability to customize copper thickness ensures that these circuits can meet the design requirements of a variety of electronic devices.

Rigid-flexible circuit:

In addition to flexible circuits, Capel also specializes in rigid-flex circuits. These circuits combine the advantages of rigid and flexible PCBs, making them ideal for applications requiring reliability and flexibility. Capel is available in 1/2 oz copper thickness. The performance of its rigid-flex circuit is higher. This enables the circuit to meet the needs of robust applications while maintaining the necessary flexibility.

Membrane switch:

Capel also produces membrane switches with extremely thin copper layers. These switches are widely used in industries that require user interface solutions, such as medical equipment and industrial control systems. The copper thickness of these membrane switches ranges from 0.005″ to 0.0010″. An ultra-thin layer of copper ensures the switch is highly responsive while maintaining the necessary durability.

Final Thoughts:

The copper thickness in a flexible PCB has a significant impact on its performance, reliability and longevity. Selecting the appropriate copper thickness based on current requirements, space constraints, flexibility and manufacturing considerations is critical. Consulting with experienced PCB manufacturers and design experts can help optimize flexible PCBs for various applications, ensuring they meet the required electrical and mechanical performance standards.

Capel is a leading supplier of flexible printed circuit boards, offering a variety of copper thickness options to meet different needs. Whether you require standard flex circuits, flat flex circuits, rigid flex circuits or membrane switches, Capel has the expertise and capabilities to deliver high quality products with the required copper thickness. By working with Capel, you can ensure your flexible PCB meets the required standards and performs optimally in your application.

Post time: Oct-11-2023

Back