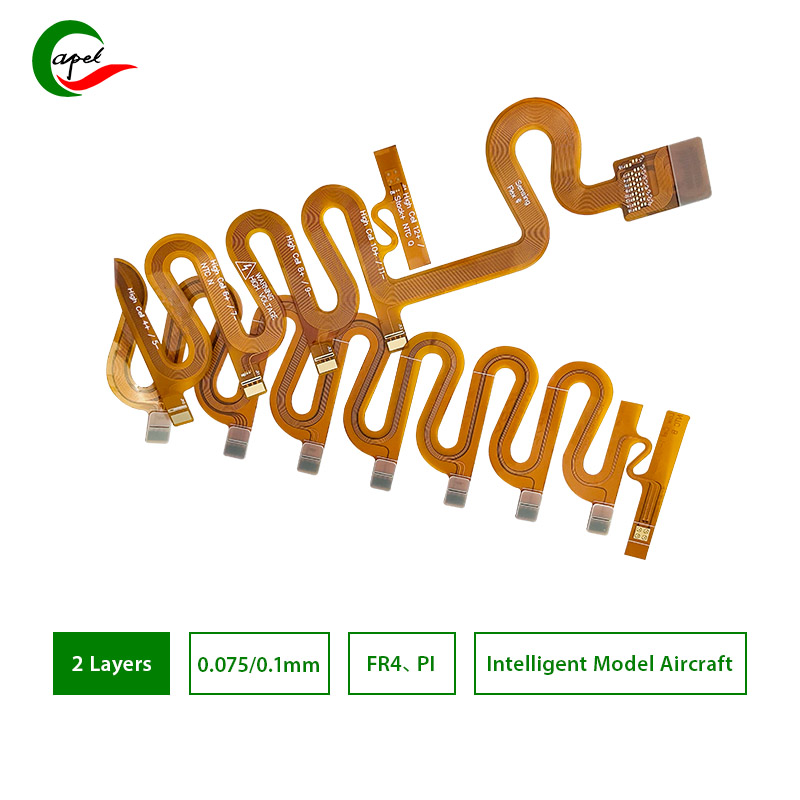

FPC circuit boards, also known as flexible printed circuit boards, play a vital role in the functionality of electronic devices. From smartphones and laptops to medical devices and automotive systems, FPC boards are used in numerous applications. The quality of these circuit boards directly affects the performance and reliability of the devices into which they are integrated. Therefore, it is crucial to be able to identify the quality of an FPC board before purchasing or integrating it into your product. In this blog post, we will discuss how to determine the quality of FPC circuit boards based on appearance and specific requirements.

The appearance of an FPC board can provide valuable insights into its overall quality. By analyzing and judging these circuit boards from three different aspects, a preliminary assessment of their quality can be made.

1. Standard rules for size and thickness

One of the first factors to consider when inspecting the appearance of an FPC board is its size and thickness. Standard circuit boards have specific dimensions and thicknesses that need to be adhered to. Customers can measure and check the thickness and specifications of circuit boards they are considering purchasing. Any deviation from standard dimensions and thickness may indicate poor quality or manufacturing defects.

2. Light and color

The outer surface of FPC circuit boards is usually covered with ink to act as an insulator. By checking the color and brightness of the boards, you can evaluate the quality of the insulation. If the color appears dull or there isn’t enough ink on the board, the insulation may not be of high quality. Insufficient insulation can cause electrical leakage and compromise the overall functionality of the circuit board.

3. Weld appearance

Efficient soldering is critical for FPC boards because they are composed of numerous components. If not soldered properly, the part can easily come off the board, which can seriously affect its quality and functionality. Therefore, it is crucial to carefully inspect the soldering appearance of the circuit board. A quality circuit board will have strong, clear solder joints, ensuring a reliable connection between components.

Determine the quality of FPC circuit boards based on specific requirements

In addition to appearance, high-quality FPC circuit boards must meet certain requirements to ensure optimal performance and durability. Here are a few key requirements to consider:

1. Electrical connection

After the components are installed, the FPC circuit board must ensure that the electrical connections meet the required standards. It should be easy to use and functional reliably without any electrical issues.

2. Line width, line thickness, line spacing

The line width, line thickness and line spacing of circuit board traces are key parameters. These specifications need to meet the required standards to prevent problems such as wiring heating, open circuits and short circuits. Proper production line design and manufacturing can prevent failures and maximize circuit board life.

3. Copper skin adhesion

The copper on the FPC circuit board should not peel off easily when exposed to high temperatures. Copper adhesion issues can lead to poor conductivity and affect the overall quality of the board. Therefore, it is necessary to ensure that the copper sheet remains intact under different temperature conditions.

4. Oxidation of copper surface

A high-quality FPC circuit board should have an oxidation-resistant copper surface. When copper is exposed to moisture or oxygen, oxidation occurs, causing a layer of corrosion. Copper oxide will quickly deteriorate and impair the performance of your circuit board. Therefore, it is crucial to verify that the copper surface is well protected and resistant to oxidation.

5. Electromagnetic radiation

Electronic devices emit electromagnetic radiation that can interfere with the surrounding environment. A high-quality FPC circuit board should minimize the additional electromagnetic radiation generated by the circuit board itself. This ensures that the equipment operates efficiently without causing interference to other sensitive components or systems.

6. Appearance and mechanical properties

The appearance of the circuit board is very important, not only for aesthetic reasons but also for functionality. The sheets should be consistent in shape and should not be deformed. The installation of FPC circuit boards is usually mechanized, and any deformation may cause screw hole misalignment or other integration issues. Ensuring that the appearance and mechanical properties meet the required standards is critical to successful installation and proper function of the circuit board.

7. Resistant to extreme conditions

FPC circuit boards may be affected by high temperatures, high humidity, or other extreme conditions, depending on their specific application. High-quality circuit boards must be designed and manufactured to withstand these conditions without causing performance issues or component damage. Special resistor characteristics should be considered during the evaluation and selection process.

8. Surface mechanical properties

The mechanical properties of the FPC circuit board surface also play a crucial role in its installation. The surface should meet the installation requirements without causing any deformation or misalignment. Any errors or misalignments in the board’s hole placement or circuitry can cause serious integration issues and affect the overall quality and performance of the electronic device.

In summary

Identifying the quality of FPC circuit boards is critical to ensuring reliable performance and durability of electronic devices. By examining the appearance and considering specific requirements such as electrical connections, wiring specifications, copper adhesion, and resistance to extreme conditions, one can make an informed decision when selecting an FPC board for their application. Following these guidelines will help you select the correct circuit board that meets the necessary quality standards and ensure optimal performance.

When evaluating the quality of FPC circuit boards, remember to pay attention to the appearance and specific requirements!

Post time: Oct-23-2023

Back